A wiring method and wiring device implementing the method

A wiring method and technology for wiring equipment, which are applied in the directions of cable laying equipment, cable installation, electrical components, etc., can solve the problems that cables are not easy to pass through, and are prone to breakage, and achieve the effect of reducing the inconvenience of wiring.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

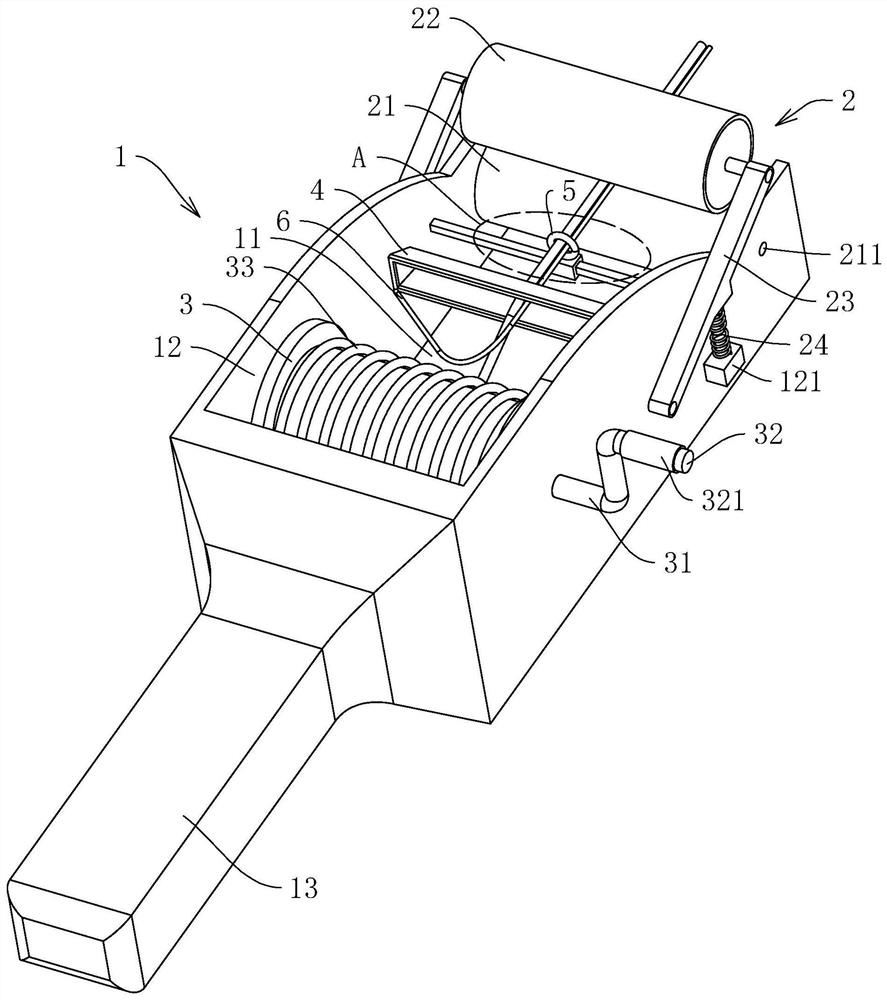

[0040] Attached to the following Figure 1-4 This application will be described in further detail.

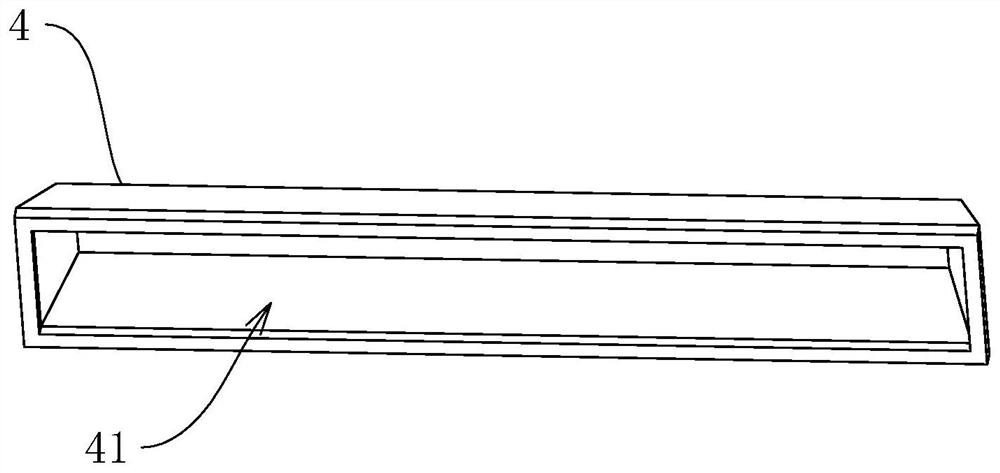

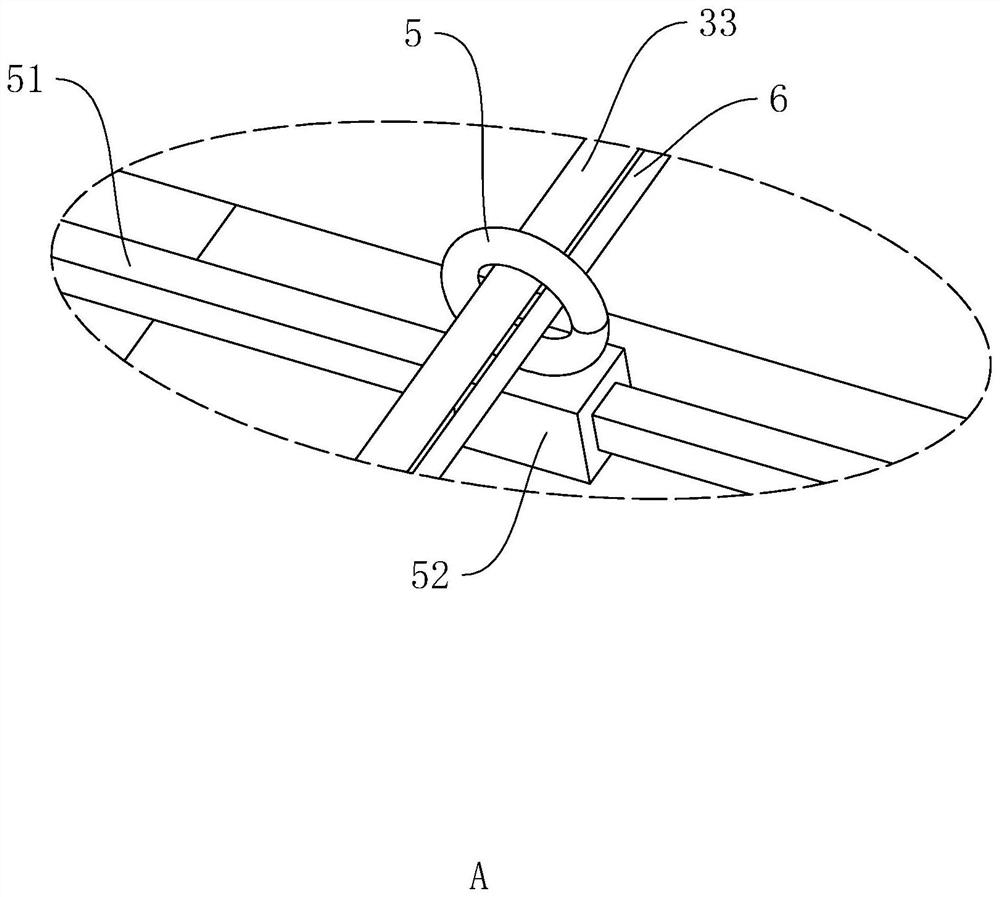

[0041] The embodiment of the present application discloses a wiring method. Including wiring equipment, the wiring equipment includes a rack 1, the rack 1 is provided with a wire tray 3, the wire tray 3 is wound with a guide wire 33, and the frame 1 is also provided with a compression guide wire 33 and a compression cable 6 component 2. Include the following steps:

[0042] (1) Guide wire laying: lead the guide wire 33 from the wire tray 3 and pass through the compression assembly 2. The guide wire 33 has a certain rigidity. Manually drag the guide wire 33 out and send it into the inlet of the pre-laid pipe , the guide wire 33 advances along the pre-laid pipe, and the end of the guide wire 33 extends out of the outlet of the pre-laid pipe;

[0043] (2) Binding cables: the cables 6 are passed through the wiring equipment and are arranged in parallel with the guide wires 33, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com