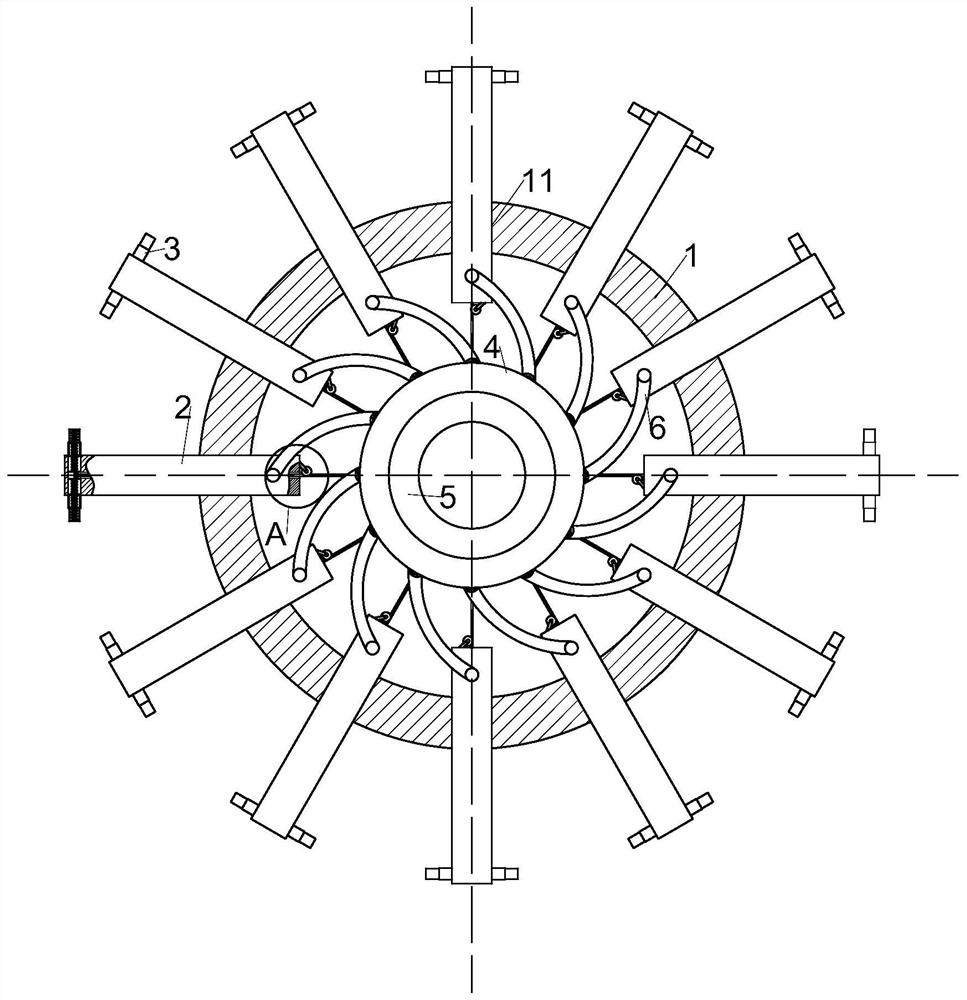

Direct-current permanent magnet motor iron core

A permanent magnet motor and iron core technology, applied in the field of motor iron core, can solve problems such as inconvenience and achieve the effect of reducing resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

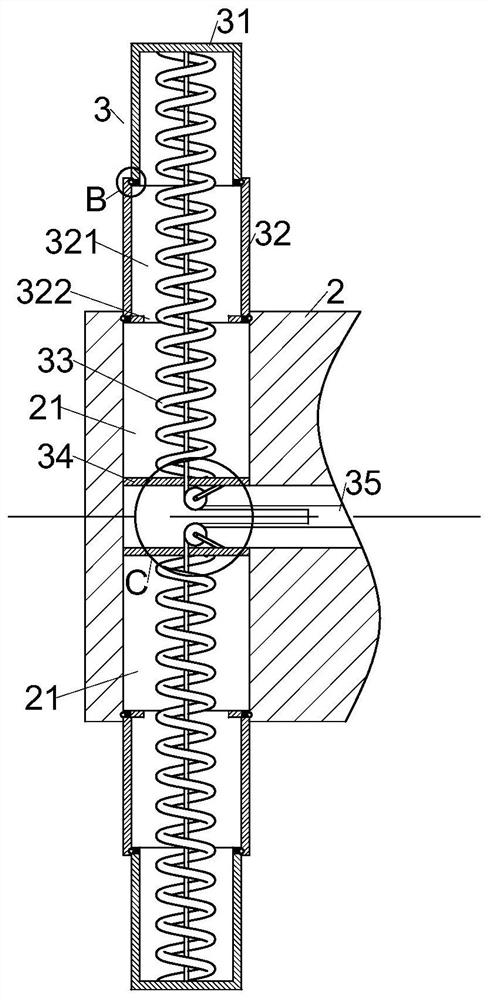

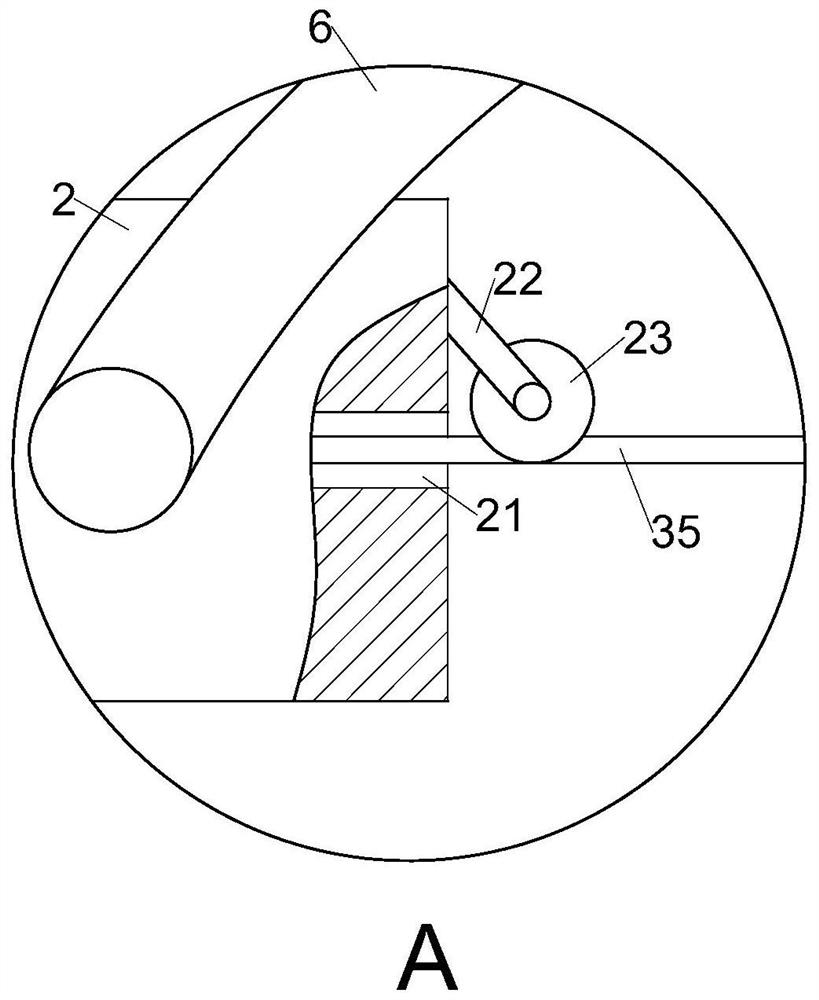

[0032] As a specific embodiment of the present invention, the inner wall of the bottom end of No. 1 telescopic rod 31 and No. 2 telescopic rod 32 is provided with No. 2 groove 323, and the No. 2 groove 323 of No. 1 telescopic rod 31 and No. 2 telescopic rod 32 All be provided with clamping ball 311 and clamping spring 312 in the groove 323, clamping ball 311 is positioned at the outside of No. One end away from the stuck ball 311 is all fixedly connected with the side inner wall of the No. 1 telescopic rod 31 and the No. 2 telescopic rod 32 and the second groove 323, and the inner surface of the No. 2 telescopic rod 32 and the winding plate 2 are all provided with the inner surface of the stuck ball. 311 is matched with the card slot 313.

[0033] When the sleeve 4 rotates counterclockwise, it drives the steel wire rope 35 to move to move the limit rod 3 to the direction of the winding plate 2. When the sleeve 4 rotates, the limit rod 3 makes the No. No. 32 telescopic rods 32...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com