A variable inductor with continuously adjustable inductance

An inductor and variable technology, which is applied in the direction of continuously variable inductors/transformers, variable inductors, inductors, etc., can solve the problems that the inductance cannot be continuously adjusted and intermittently adjusted, and achieve It is convenient for manual winding, maintains continuity, and has the effect of high precision of inductance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0044] Please refer to Figure 1 to Figure 14 , Embodiment 1 provided by the present invention is:

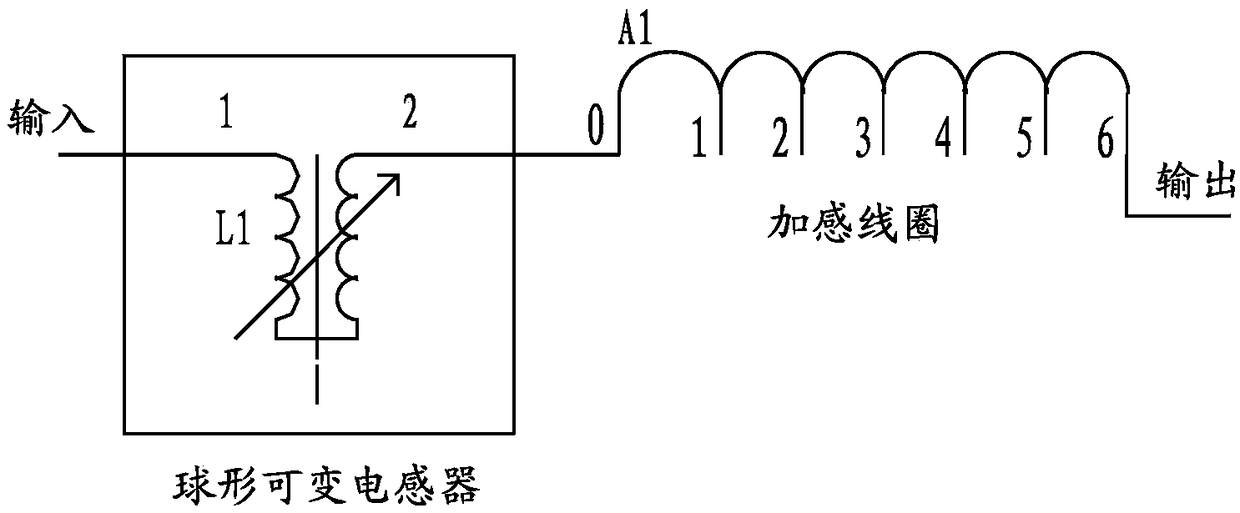

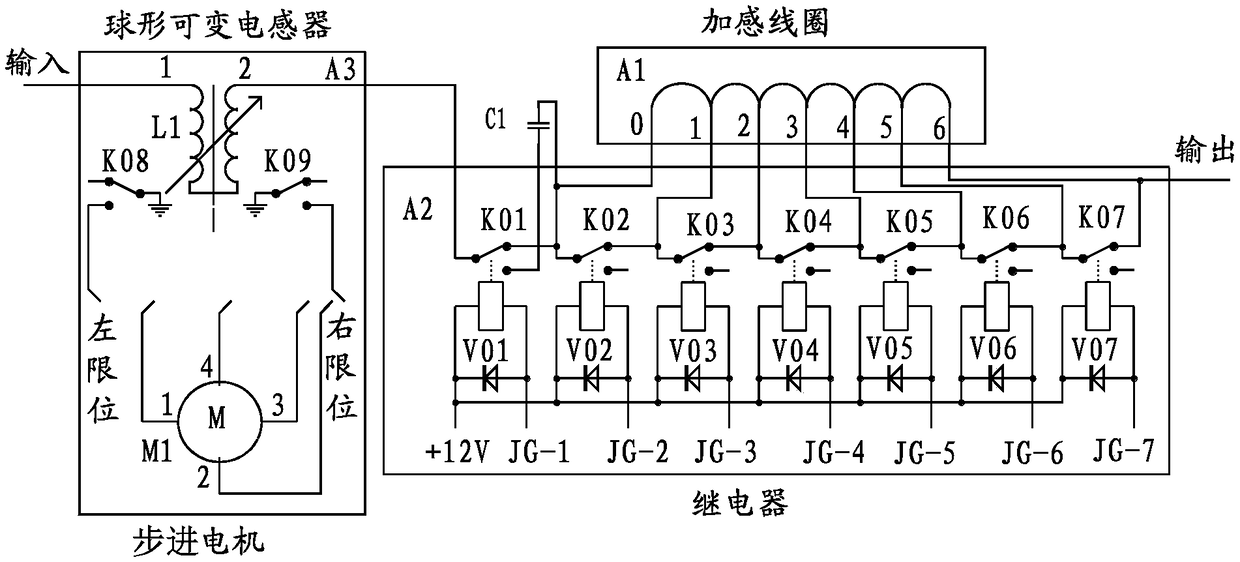

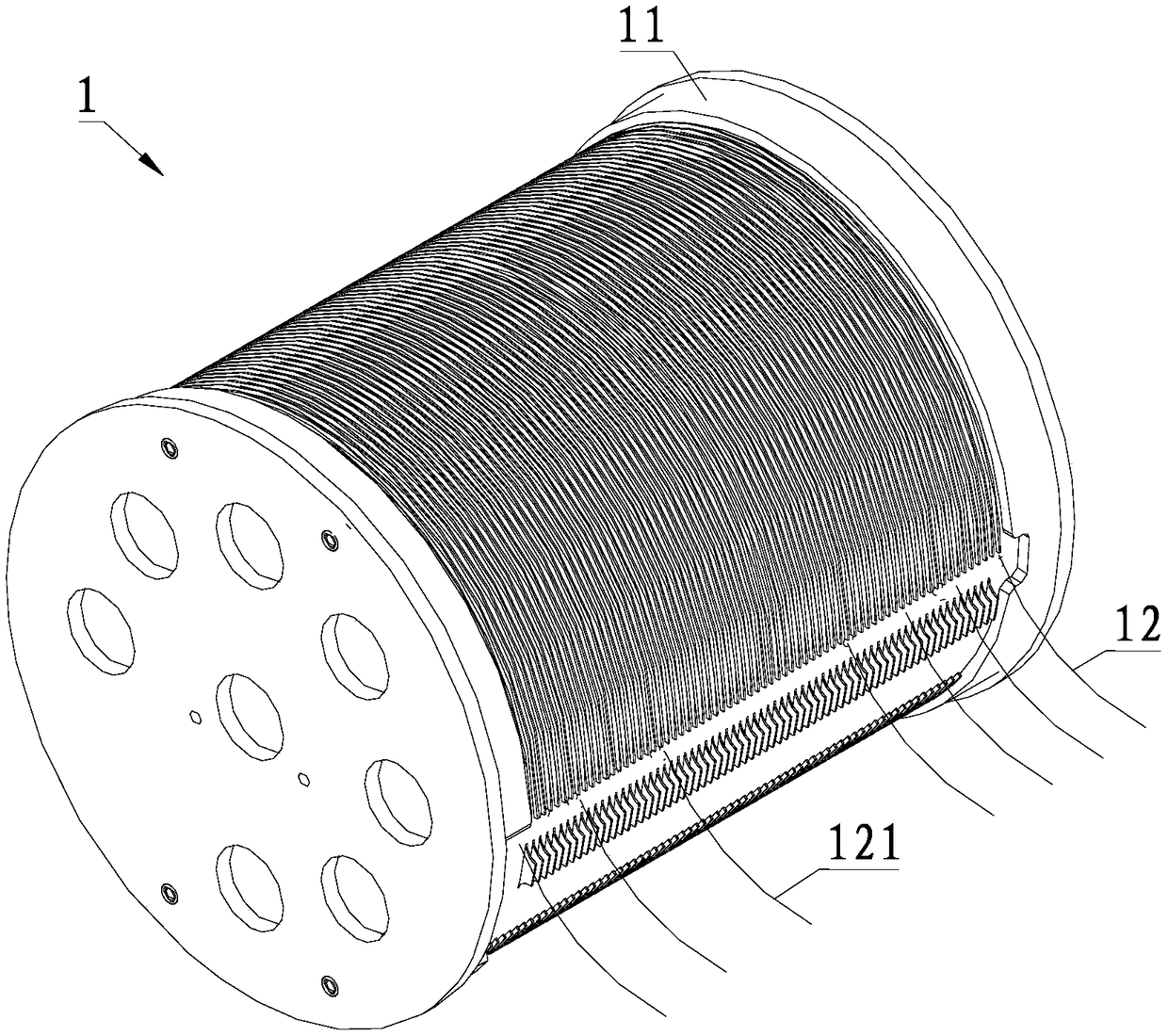

[0045] A variable inductor with continuously adjustable inductance, comprising a first variable inductor 1 and a second variable inductor 2, the first variable inductor 1 includes a loading coil 12, the The loading coil 12 includes at least one tap 121; the second variable inductor 2 includes a spherical variable inductor 21, and the spherical variable inductor 21 includes a rotor core 211, a rotor coil, a stator core 212, stator coil, rotor bracket 213 and stator bracket 214, the rotor core 211 is spherical, the spherical surface of the rotor core 211 is distributed with helical first grooves 2111, and the rotor coil is wound on the first In a groove 2111, the stator core 212 is hollow spherical, and the spherical surface of the stator core 212 is distributed with helical second grooves 2121, and the stator coil is wound in the second groove 2121, The rotor core 211 is insta...

Embodiment 2

[0050] Embodiment two provided by the present invention is:

[0051] On the basis of the first embodiment, further, the first variable inductor 1 further includes a bobbin 11, the loading coil 12 is wound on the bobbin 11, and the bobbin 11 is provided with There are a plurality of clamping projections 111 arranged side by side in the circumferential direction, the distance between adjacent clamping projections 111 is adapted to the diameter of the loading coil 12, and the height of the clamping projections 111 is and the width are smaller than the diameter of the loading coil 12, and each of the clamping protrusions 111 is provided with a routing opening 1111, and the loading coils 12 are alternately stacked and wound on the bobbin 11. The loading coil 12 on the bottom layer is wound on both sides of the clamping protrusion 111, and the loading coil 12 on the top layer is wound close to and wound between two adjacent turns of the loading coil 12 on the bottom layer. During w...

Embodiment 3

[0055] Embodiment three provided by the present invention is:

[0056] On the basis of the second embodiment, further, each of the clamping protrusions 111 is provided with a retaining protrusion 1112, and the height of the retaining protrusion 1112 is greater than or equal to the diameter of the loading coil 12 2 times, the wire retaining protrusion 1112 is in contact with the wire routing opening 1111, and the wire retaining protrusion 1112 is located at the front end of the wire routing opening 1111 along the wire winding direction.

[0057] The wire retaining protrusion 1112 can not only position the loading coil 12 on the bottom layer, but also position the loading coil 12 on the top layer, thereby further improving the winding precision of the loading coil 12 in length and facilitating manual winding. During the process of manufacturing the loading coil 12, the loading coil 12 located on the top layer can be accurately positioned, which is convenient for manual mass prod...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com