Double-nozzle concrete printing device and printing method

A printing device and concrete technology, applied in the field of 3D printing, to achieve good industrial application value and fast cleaning effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] The present invention will be described in further detail below in conjunction with the accompanying drawings.

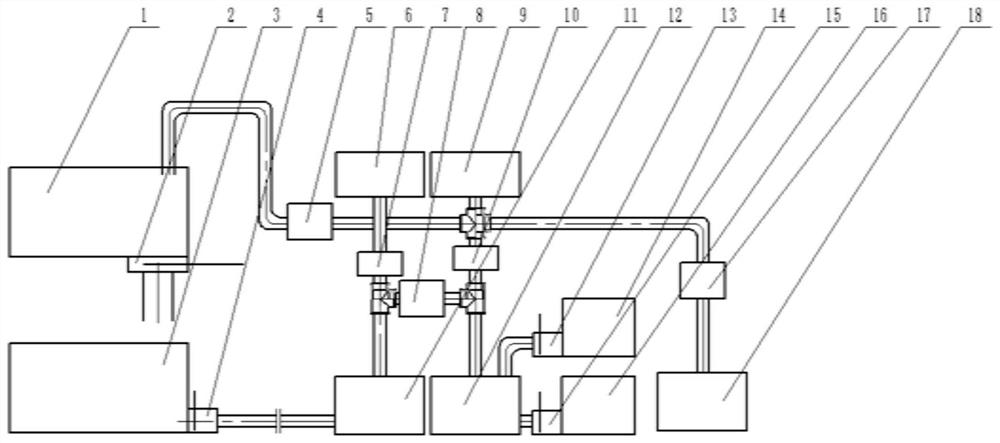

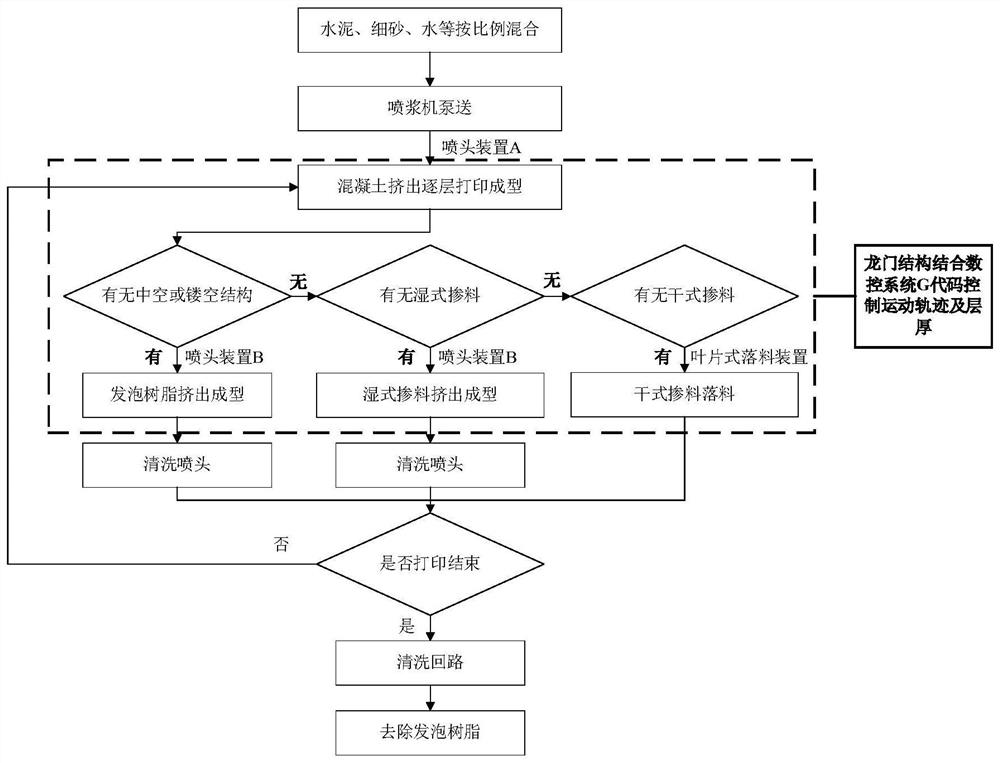

[0039] refer to figure 1 with figure 2 The simplified schematic diagram of the process and structure shown in the present invention includes a double-nozzle concrete printing process, which includes the transmission of concrete slurry, foamed resin or (and) other necessary admixtures, the distribution of the printing process, and the concrete slurry. The transportation and addition of required additives, the printing and modification of building structural parts, the timely cleaning of the nozzles in the printing gap during the printing process, and the cleaning of the pipelines and nozzles after printing. Among them, the transmission of concrete slurry is realized by using the mixer 1 and the spraying equipment 3. After the cement, fine sand and water are fully stirred in the mixer 1, the opening and closing valve 2 is opened and the materials are dropped ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com