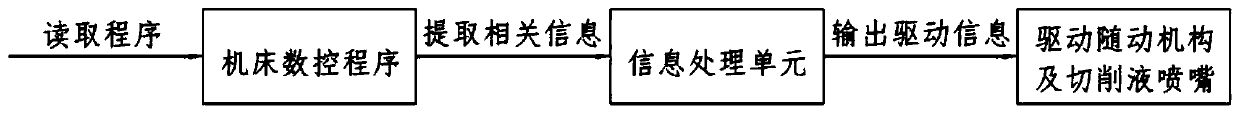

Intelligent cutting fluid follow-up system for machine tool

A follow-up system and cutting fluid technology, applied in metal processing machinery parts, maintenance and safety accessories, metal processing equipment, etc., can solve the problems of complex structure, excessive local liquid supply, waste of cutting fluid, etc., and reduce the temperature in the cabin. , prolong the service life, improve the effect of the working environment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

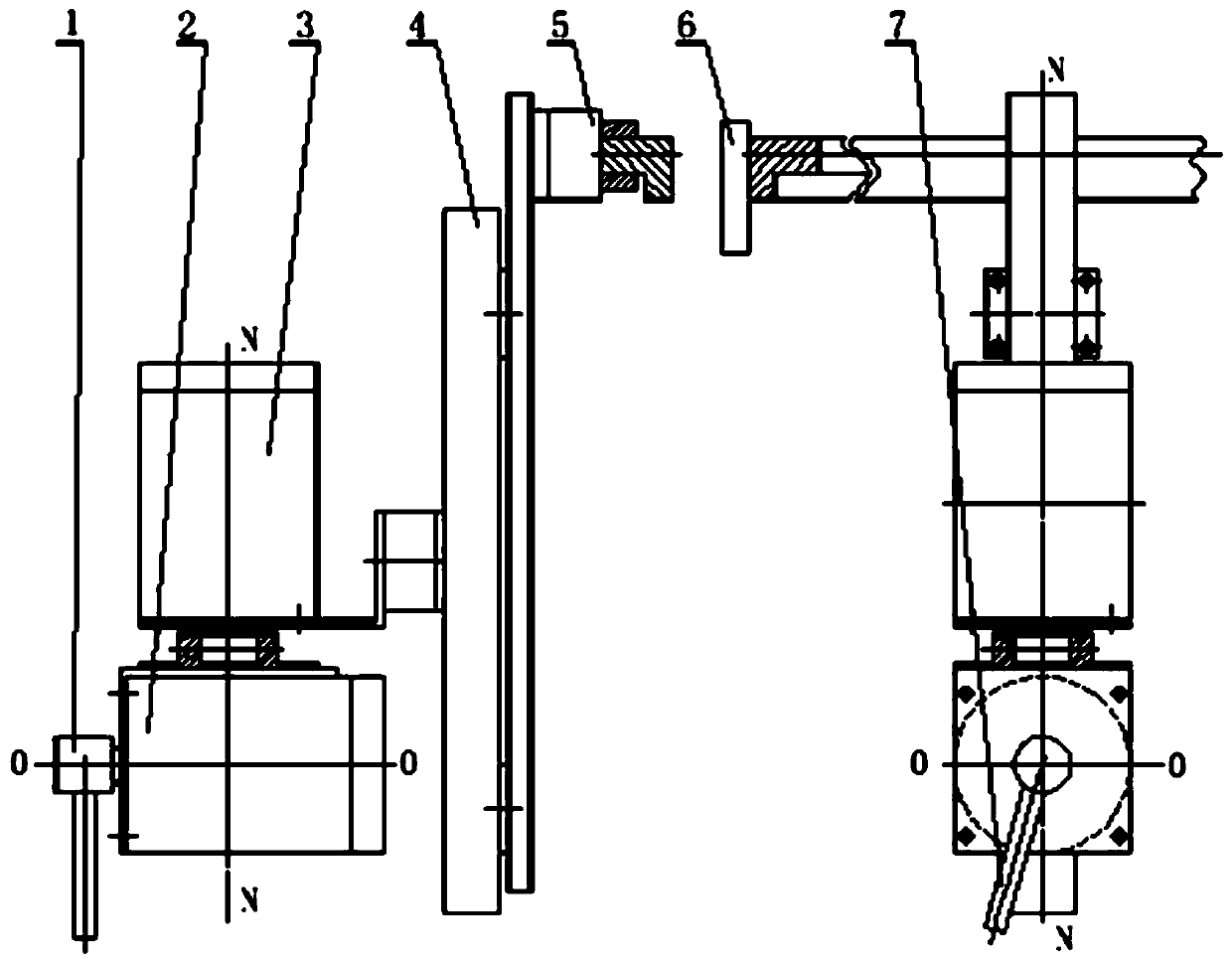

[0024] The present invention will be further described below in conjunction with the accompanying drawings and embodiments, and the present invention includes but not limited to the following embodiments.

[0025] The present invention can automatically select and control the injection target and injection angle of the nozzle of the cutting fluid follower device through manual preset or automatic search for the target area where the cutting fluid is sprayed, and automatically identify the injection position and autonomously adjust the cutting fluid during the machining process of the machine tool Injection pressure and flow rate, real-time feedback cutting fluid injection target area. The invention utilizes intelligent control technology to independently seek, intelligently control, and independently adjust cutting fluid nozzles for machine tools, and belongs to a three-in-one, finely managed machine tool subsidiary subsystem.

[0026] The present invention avoids the traditio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com