Electric current transducer capable of being installed on line and manufacturing method

A technology of current sensor and manufacturing method, which is applied in the direction of measuring current/voltage, instrument, measuring device, etc., can solve the problems of low accuracy and resolution of current transformer and current transformer, and achieve convenience for manual winding, high measurement accuracy, The effect of high measurement accuracy and resolution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

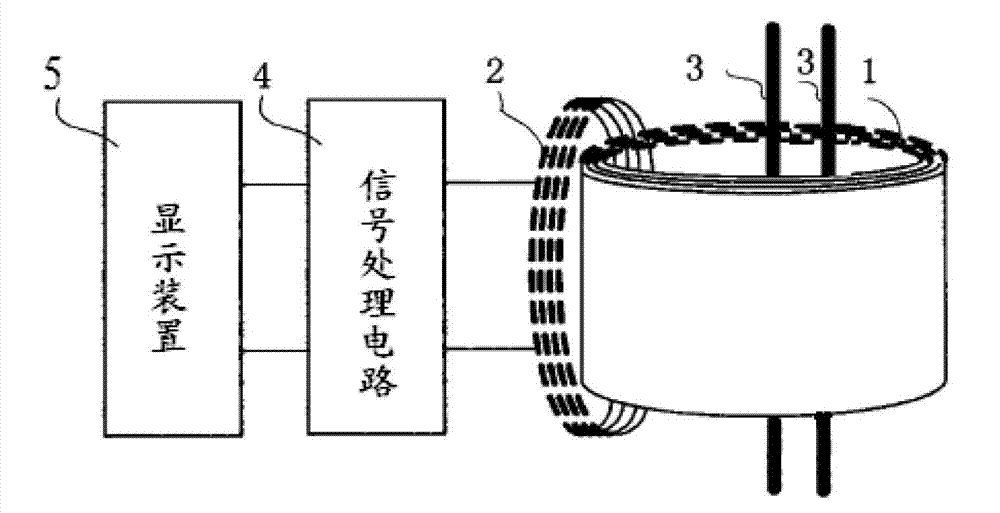

[0037] Such as figure 1 As shown, it is the structure of a current sensor that can be installed online according to an embodiment of the present invention. A current sensor that can be installed online according to an embodiment of the present invention includes:

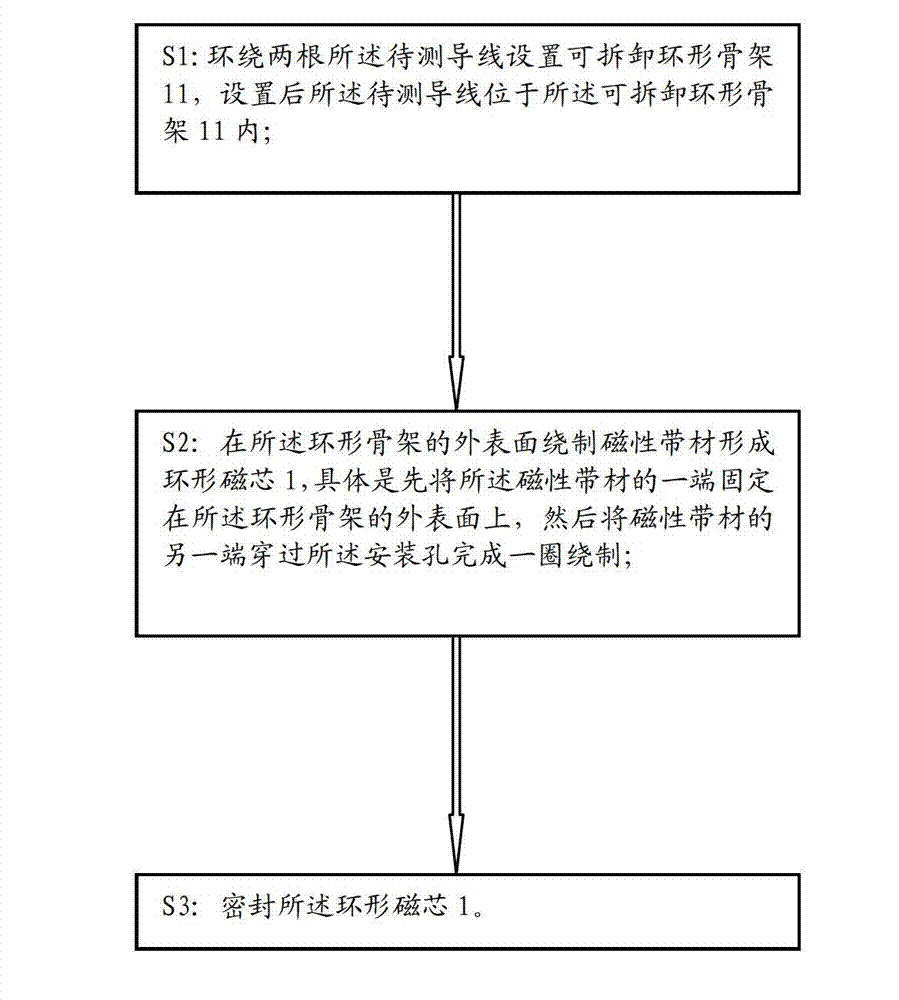

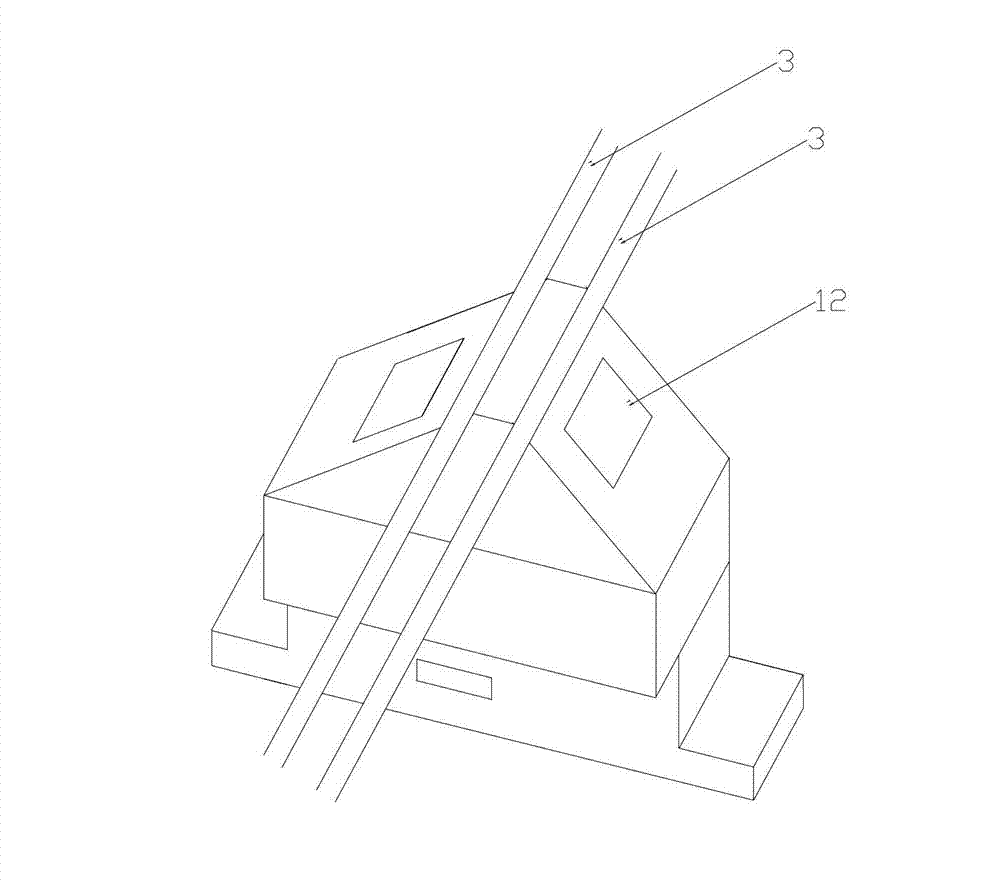

[0038] The annular magnetic core 1 is used to induce the magnetic field around the two wires 3 to be tested; wherein, the annular magnetic core 1 is wound on-site by a magnetic strip around the wires 3 to be tested, and after winding, the wires 3 to be tested are all located at In the annular magnetic core 1; in the present embodiment, the two wires 3 to be tested are two DC wires flowing into and out of the same electrical equipment, and the space of the two wires under the condition of no leakage Synthetic electromagnetic field is zero; As a specific embodiment, the magnetic strip is a slope film alloy strip with a thickness between 8um-10um; the thickness of the slope film alloy strip is between 8um-10um, which e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com