Cabin cover automatic welding wire feeding machine head trolley

An automatic welding and hatch cover technology, which is applied in welding equipment, auxiliary welding equipment, welding/cutting auxiliary equipment, etc., can solve the problem of the need to pay attention to the position of the machine head and keep moving, the loss of welding quality monitoring, the impact of welding quality and efficiency, etc. question

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The specific implementation manners of the present invention will be further described below in conjunction with the drawings and examples. The following examples are only used to illustrate the technical solution of the present invention more clearly, but not to limit the protection scope of the present invention.

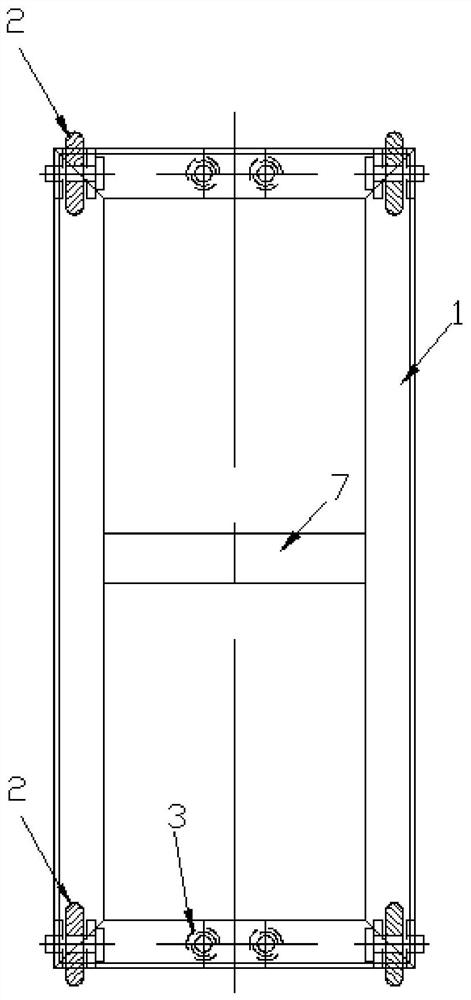

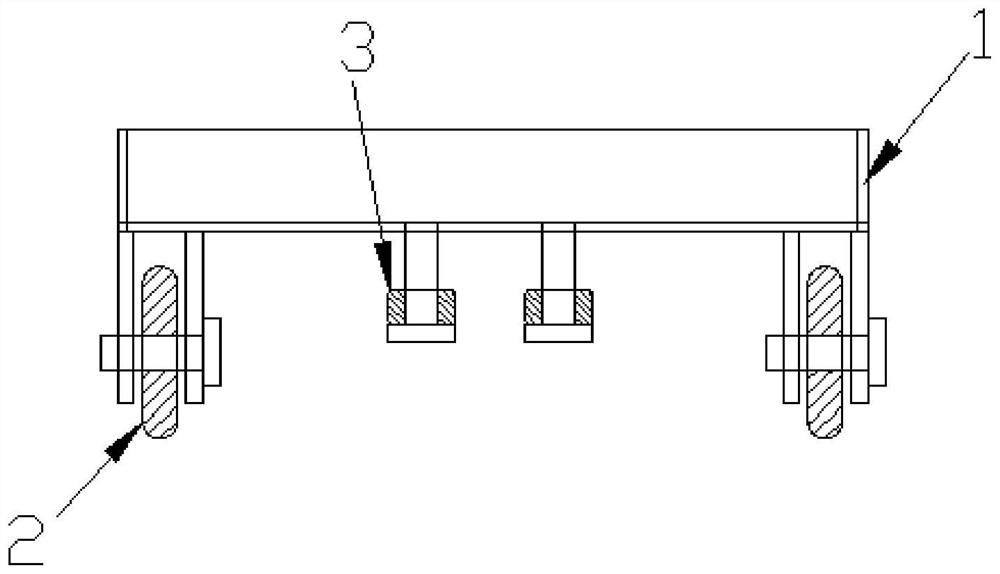

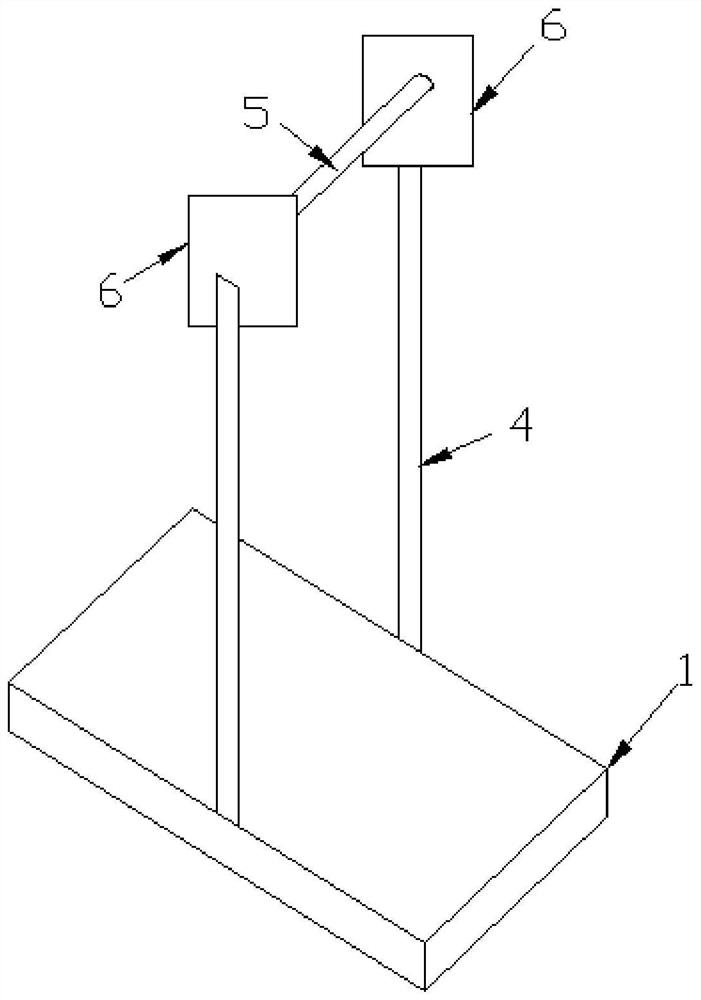

[0017] like Figure 1 to Figure 4 As shown, the present invention is a hatch cover automatic welding wire feeder head trolley, comprising a base 1 in the form of a frame structure, the base 1 is rotatably provided with vertical rollers 2 for the trolley to travel, and the base 1 is also rotatably set to be pressed against the hatch cover. A horizontal roller 3 adapted to the tight strip for guiding and limiting; two uprights 4 are fixedly arranged on the frame, and the top of the uprights 4 is rotatably connected to the support plate 6 of the welding wire reel 5 through a joint bearing, and the welding wire reel 5 is fixedly connected to the support plate 6...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com