Visible safety valve

A safety valve and spool technology, applied in the field of safety valves, can solve the problems of being unable to judge whether the equipment is working normally, whether the safety valve is open or not, increasing the work intensity of inspection personnel, etc., achieving high compactness, simple structure, and reduced weight Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

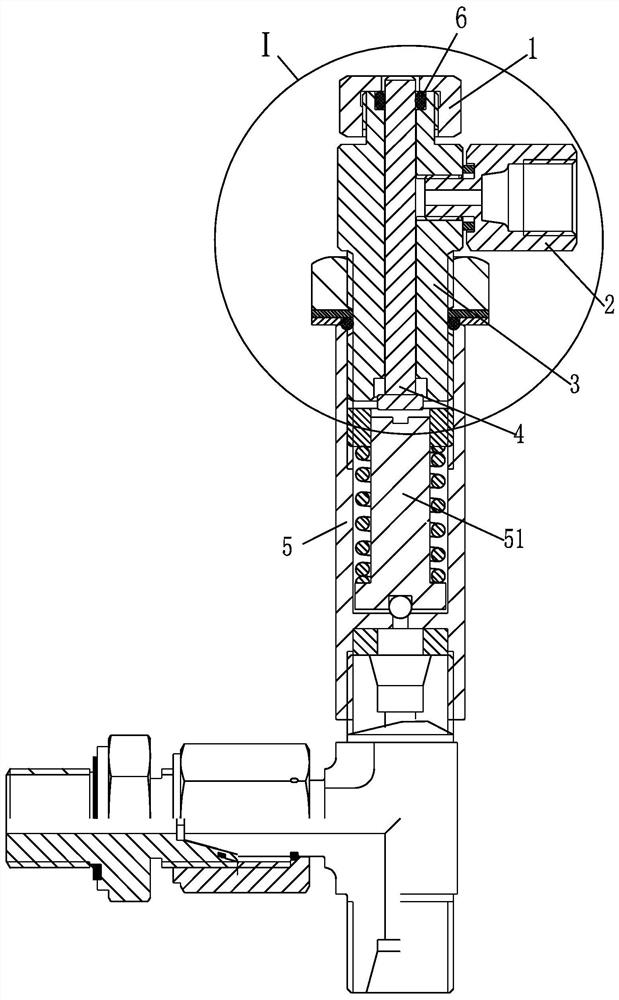

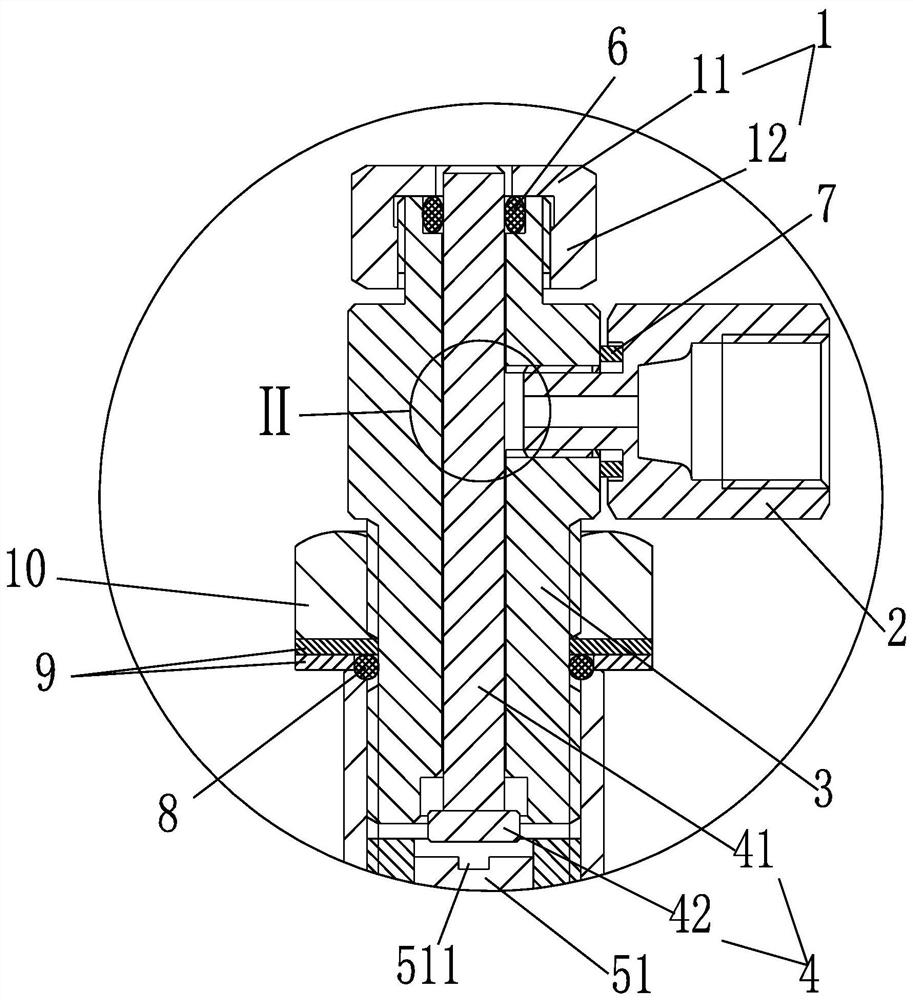

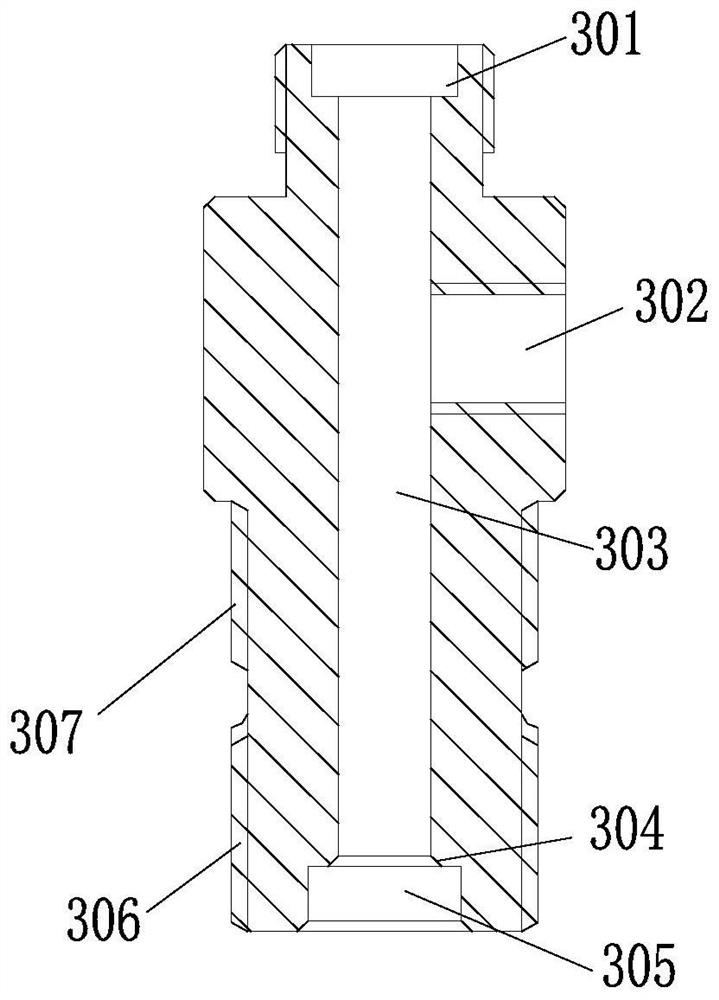

[0022] figure 1 It is a structural schematic diagram of the present invention, figure 2 for figure 1 Schematic diagram of the enlarged structure at I, image 3 It is a structural schematic diagram of the indicator rod seat of the present invention, Figure 4 for figure 2 The schematic diagram of the enlarged structure at II; as shown in the figure, the visible safety valve in this embodiment at least includes a safety valve body 5 and an indicator rod 4, and the indicator rod 4 can be set along the spool 51 of the safety valve body. The fixed direction drive is installed on the safety valve body, so that the opening and closing of the safety valve body can be judged by observing the position of the indicator rod; this structure can not only facilitate the inspection of the working state of the safety valve (safety valve opening / closing), thereby improving The safety of equipment operation also reduces the working intensity of the staff to check the state of the safety va...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com