Ship plate groove diagram drawing method and device based on CAD

A groove and ship plate technology, which is applied in the field of CAD-based ship plate groove drawing method and device, can solve the problems of low efficiency, cumbersome process, error-prone and so on.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

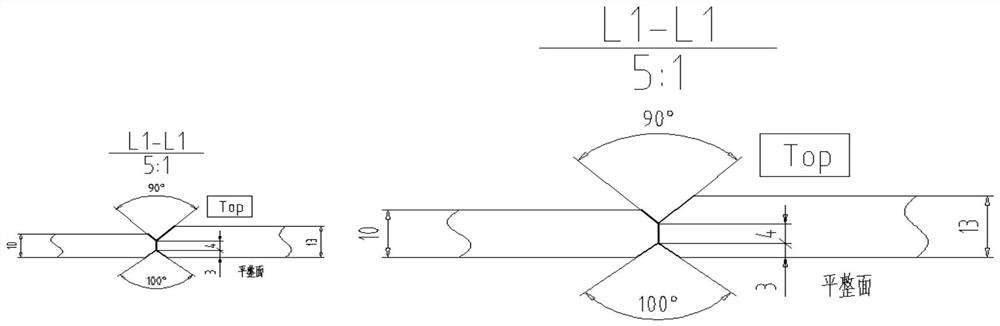

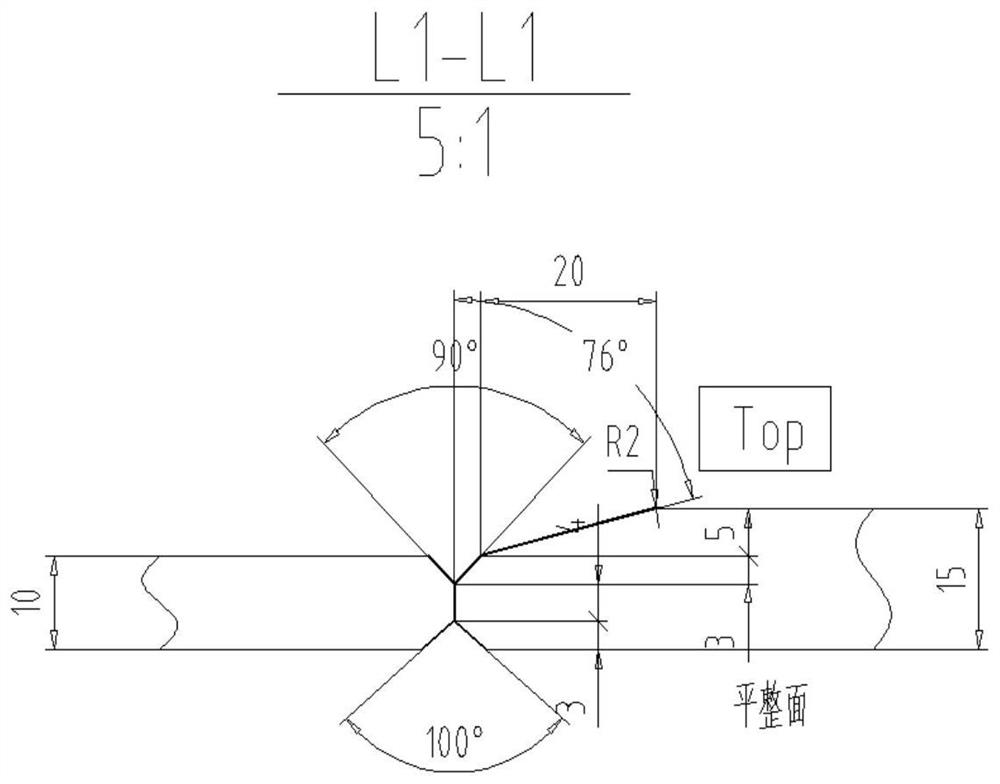

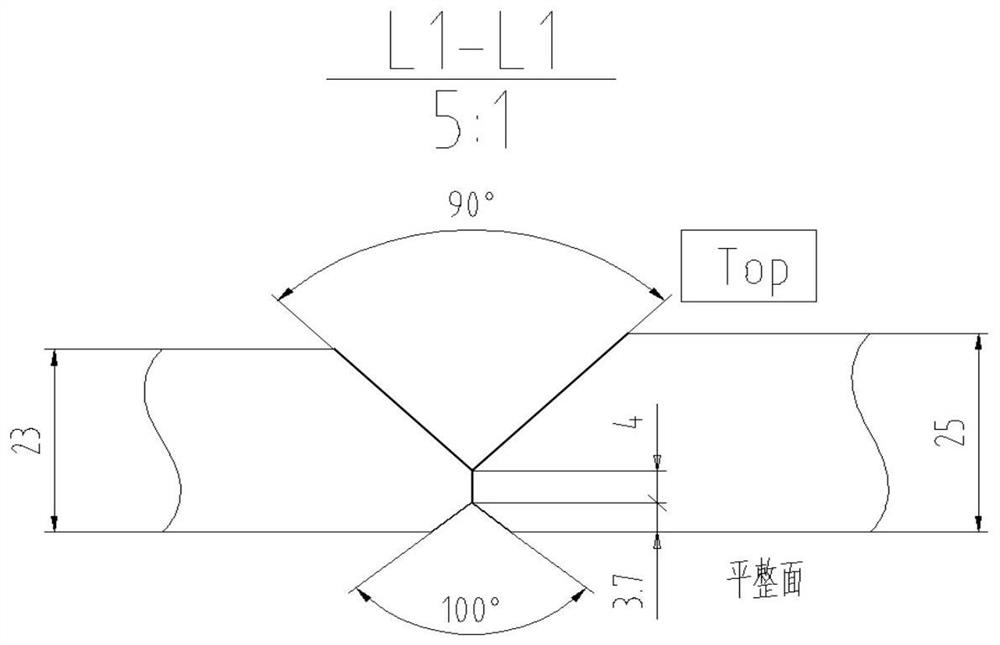

[0031] The invention relates to a CAD-based method for drawing ship plate groove diagrams, which is used for automatically drawing different groove diagrams. Among them, there are many ways to connect the groove, such as the groove connection between two plates, and the groove is provided at one end of a plate. The present invention can replace manual and automatic drawing of the groove pattern and improve the efficiency.

[0032] First of all, four drawing rules are introduced for left thin and right thick, wherein the four drawing rules are prepared in advance by welding technicians and can be called directly in this embodiment. The 4 drawing rules correspond to 6 different groove application diagrams, including all situations used in daily work. The 6 groove application diagrams are drawn and saved in advance as callable elements, which is convenient for subsequent drawing and calling.

[0033] Among them, in practical applications, the groove is divided into two types, one...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com