A kind of equipment for scraping off the glue on the surface of tempered glass

A glass surface, viscose technology, applied in chemical instruments and methods, cleaning methods and utensils, cleaning methods using tools, etc., can solve problems such as damage, time-consuming and laborious, and achieve improved convenience, uniform scraping, and scraping work. smooth effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

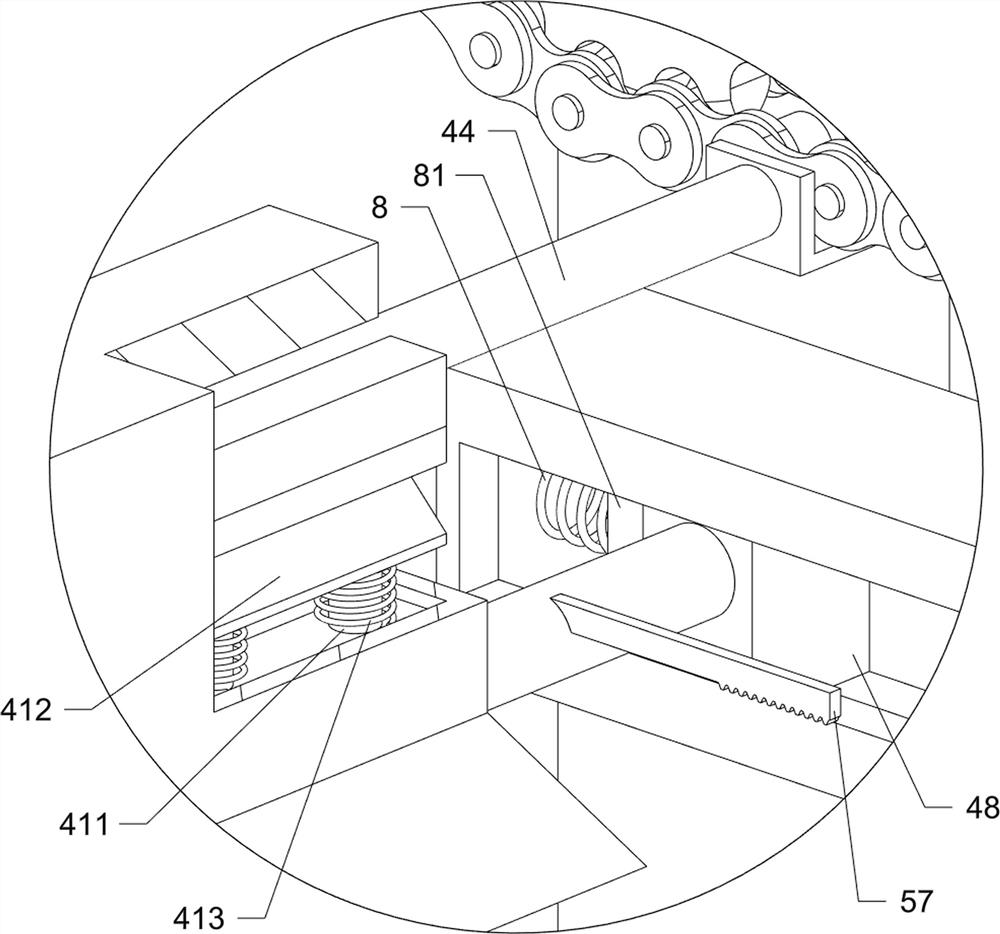

[0029] A device for scraping off tempered glass surface viscose, such as figure 1 , figure 2 , image 3 , Figure 5 , Image 6 with Figure 8 As shown, it includes a base 1, a gear motor 2, a clamping assembly 3 and a rubber scraper assembly 4. A gear motor 2 is provided on the left rear side of the base 1, and a clamping assembly 3 is provided in the upper middle of the base 1. The gear motor 2 and the base 1 is provided with scraper assembly 4.

[0030] People place the tempered glass that needs to be scraped off the surface glue in the clamping assembly 3, fix the tempered glass through the clamping assembly 3, start the reduction motor 2, and the output shaft of the reduction motor 2 will drive the scraping assembly 4 to work, thereby Scrape off the glue on the surface of the toughened glass. After the work is completed, turn off the reduction motor 2 and take out the toughened glass.

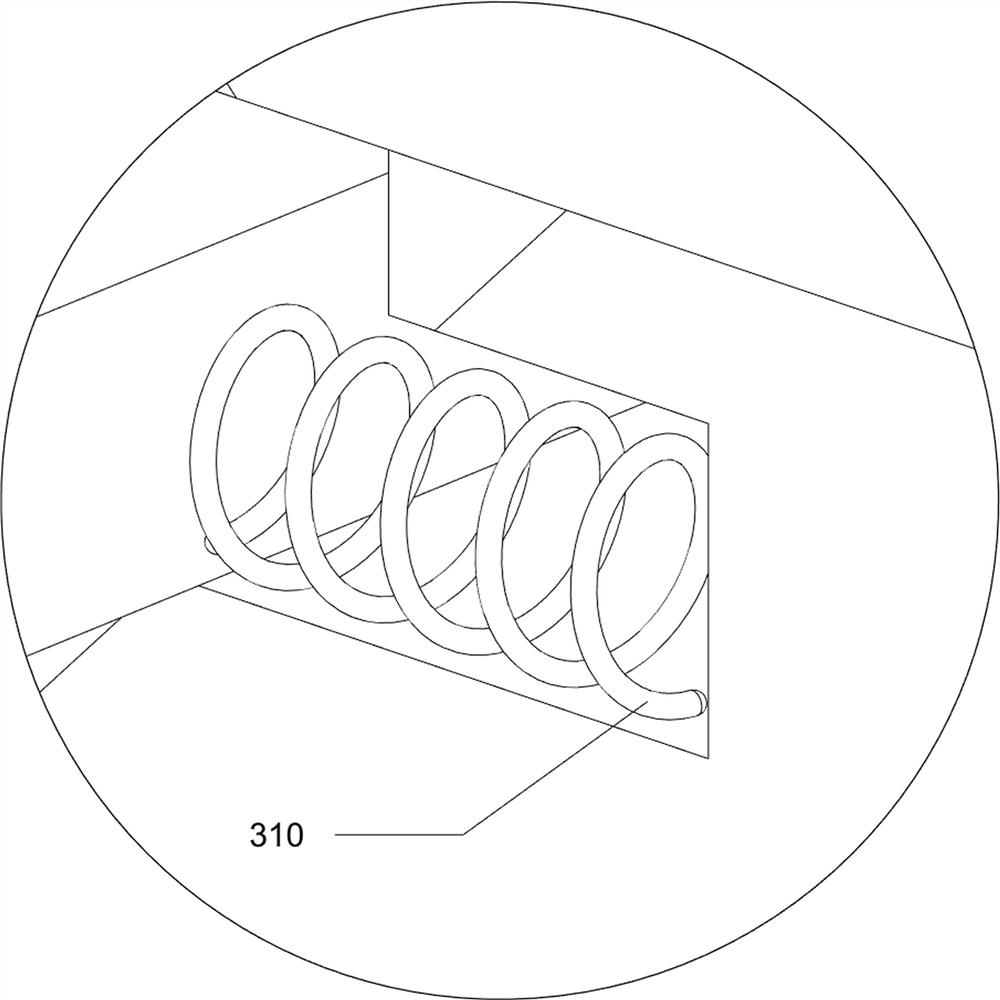

[0031] The clamping assembly 3 includes a first support plate 31, a bearing plat...

Embodiment 2

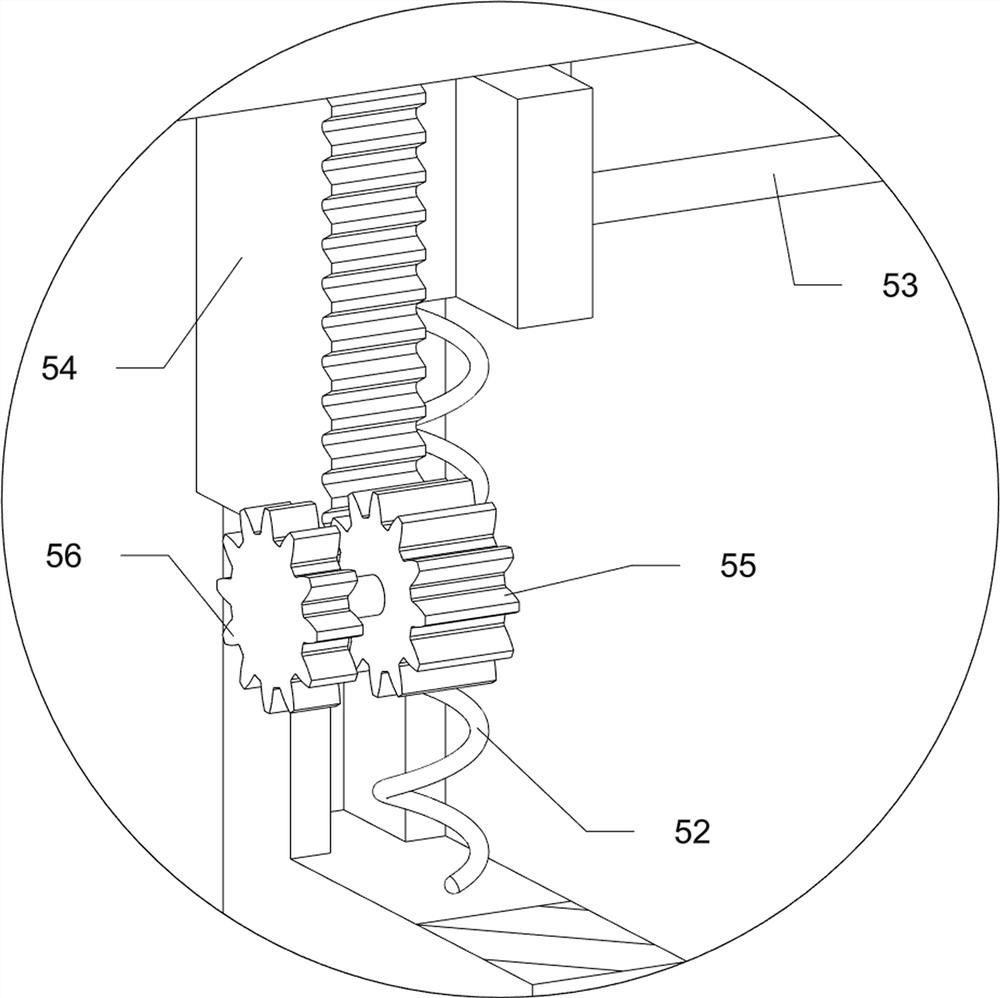

[0036] On the basis of Example 1, such as figure 2 , Figure 4 , Figure 5 , Image 6 , Figure 7 with Figure 8 As shown, it also includes a glue-taking assembly 5, and the glue-taking assembly 5 includes a fourth support plate 51, a fourth spring 52, a second knife block 53, a first rack 54, a first gear 55, a second gear 56, The second rack 57 and the material storage frame 58, the base 1 is provided with a fourth support plate 51 on the left and right sides of the upper front part, and the second knife block 53 is provided slidingly between the fourth support plate 51 top, and the second knife block 53 A fourth spring 52 is connected between both sides and the fourth support plate 51, a first gear 55 is rotatably provided on the outside of the fourth support plate 51, a first rack 54 is provided on both sides of the second knife block 53, and a first rack 54 is provided on both sides of the second knife block 53. A gear 55 meshes with the first rack 54, the first gea...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com