Rapid replacement device for RG-RH vacuum degassing furnace tank car drag chain

A vacuum degassing furnace, RG-RH technology, applied in the direction of lifting device, lifting frame, etc., can solve the problems of difficult replacement, heavy pipeline weight, difficult replacement operations, etc., to achieve good promotion value, save manpower, and improve efficiency. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

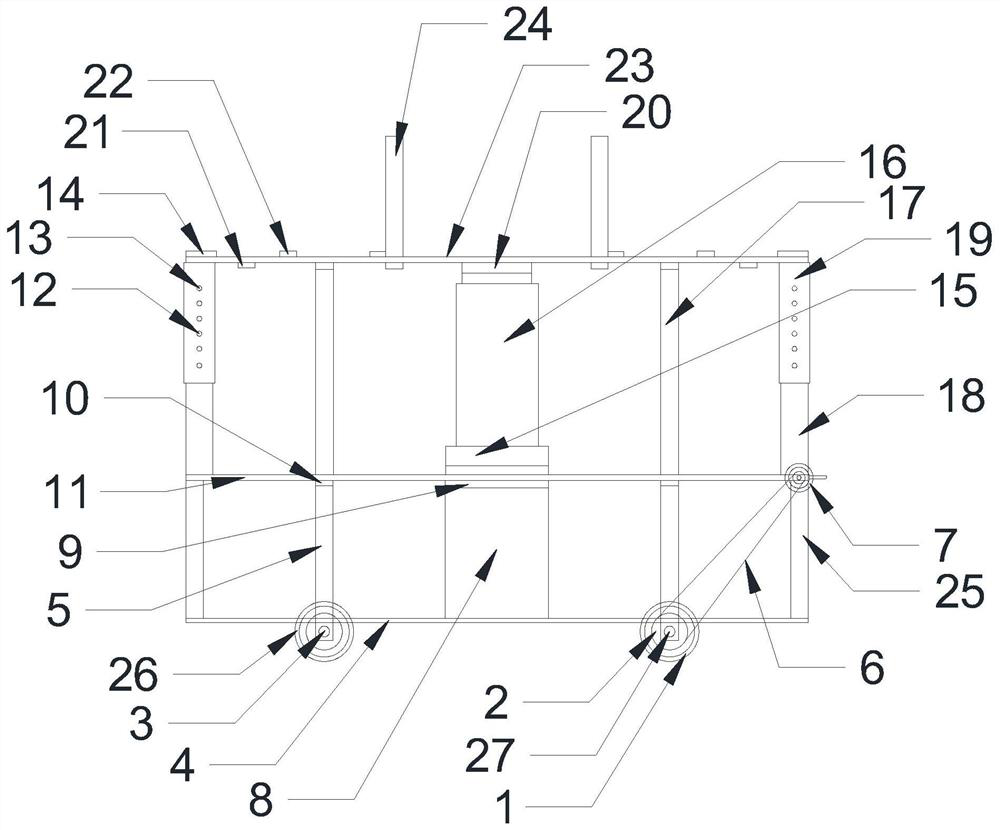

[0011] The present invention is described in further detail now in conjunction with accompanying drawing.

[0012] Such as figure 1 As shown, a RG-RH vacuum degassing furnace tank car drag chain quick replacement device, including a base plate 4, is characterized in that: the upper end of the base plate 4 is provided with support plates 25 on both sides, and the upper ends of the two support plates 25 are provided with two layers. There are lifting devices around the upper end of the board 11 and the second floor board 11. The upper end of the lifting device is provided with a jacking frame beam 23. The upper end of the jacking frame beam 23 is provided with frame side beams 14 on both sides, and the upper middle of the bottom plate 4 is provided with a support beam. 8. The upper end of the support beam 8 is provided with a bottom beam 9, and the bottom beam 9 passes through the second-layer board 11 and the upper end is provided with a base 15, the upper end of the base 15 is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com