A preparation method of coal tar pitch-based carbon material with controllable microscopic morphology

A technology of microscopic morphology and coal tar pitch, which is applied in the field of preparation of coal tar pitch-based carbon materials, can solve problems such as good structural orientation of carbon materials, low expansion rate, and difficulty in single-segment dispersion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] Example 1 (Comparative Example 1)

[0027] First, take 100g of medium-temperature coal tar pitch, add it to the reaction kettle and heat it up to 180°C, stir and react under nitrogen protection for 0.5h, and cool down to room temperature after the end; Min heating to 1100 ℃, high temperature carbonization for 3 hours, to obtain untreated coal tar-based carbon material, the 002 layer spacing of untreated coal tar-based carbon material XRD is 0.355nm.

Embodiment 2

[0028] Example 2 (Comparative Example 2)

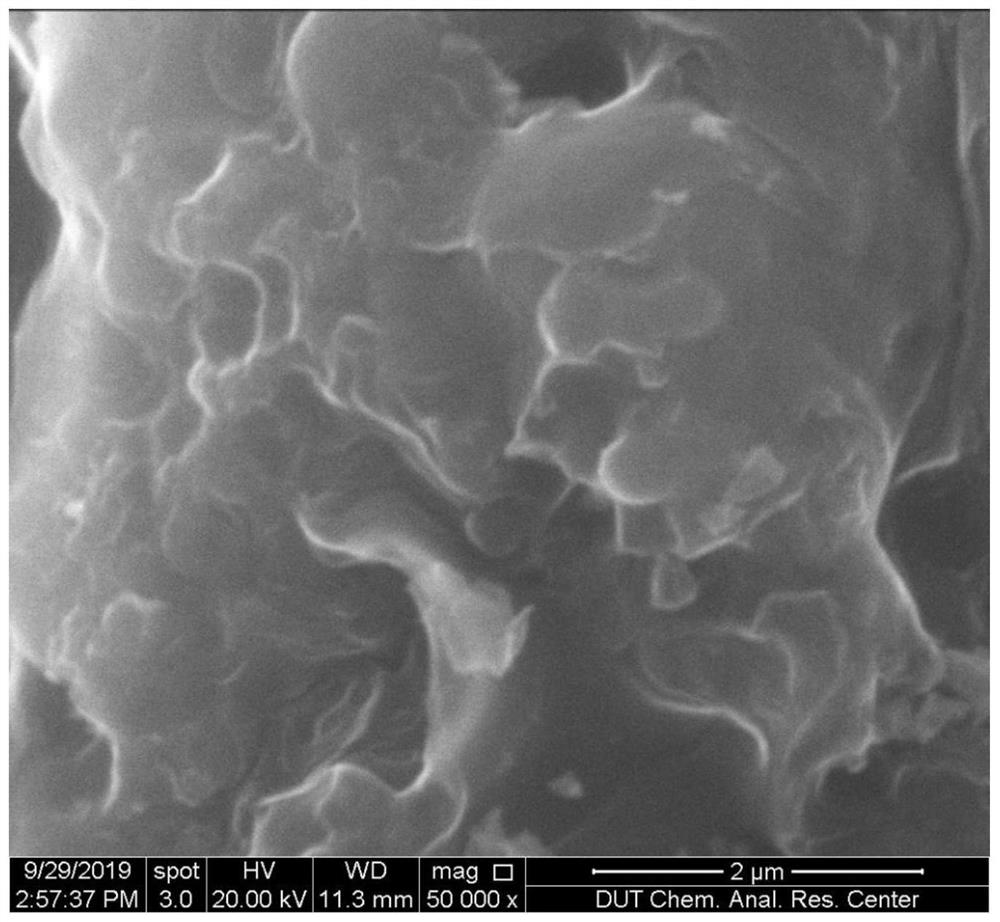

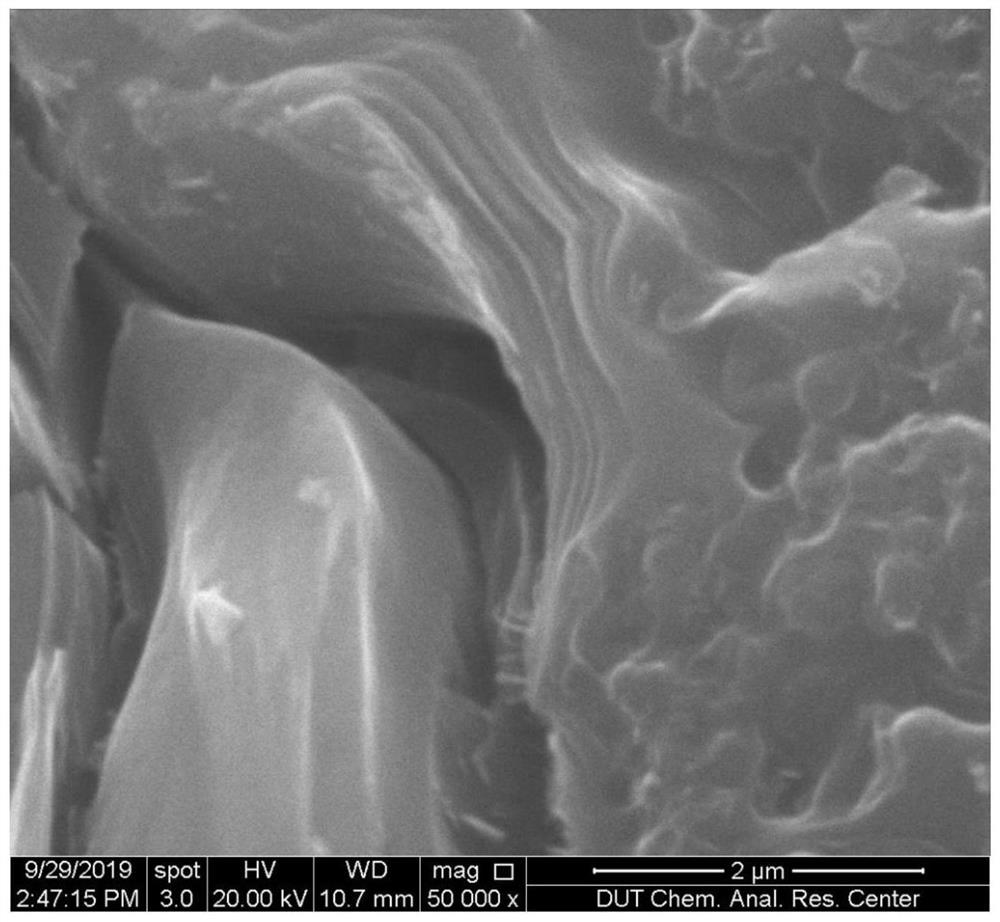

[0029] First, take 0.3 g of naphthenic acid imidazoline and 100 g of medium-temperature coal tar pitch, add them to the reaction kettle and heat up to 180 ° C, stir and react under nitrogen protection for 0.5 h, and then cool to room temperature after completion; put the above-mentioned pretreated coal tar pitch into the carbonization furnace, Under argon atmosphere, the temperature was raised to 1100°C at 0.5°C / min, and carbonized at high temperature for 3 hours to obtain naphthenic acid pretreated coal tar-based carbon material. figure 1 It is the SEM image after carbonization of coal pitch in Example 1, figure 2 This is the SEM image after carbonization of coal tar pitch pretreated with naphthenic acid imidazoline. The morphology of carbon materials before and after treatment has no obvious change, and no layered structure appears. is 0.353nm.

Embodiment 3

[0031] Step 1: First, take 0.3 g of naphthenic acid imidazoline and 100 g of medium-temperature coal tar pitch, add them to the reaction kettle and heat up to 180 ° C, stir and react for 0.5 h under nitrogen protection, and cool to room temperature after completion.

[0032]Step 2: Take 50 g of naphthenic acid imidazoline pretreated coal tar pitch and 20 g of styrene, add them into the reaction kettle, heat up to 140°C under nitrogen protection, and after 6 hours of constant temperature reaction, heat up to 200°C and distill under reduced pressure until no monomer remains. , the monomer conversion rate of in-situ polymerization was 50.2%.

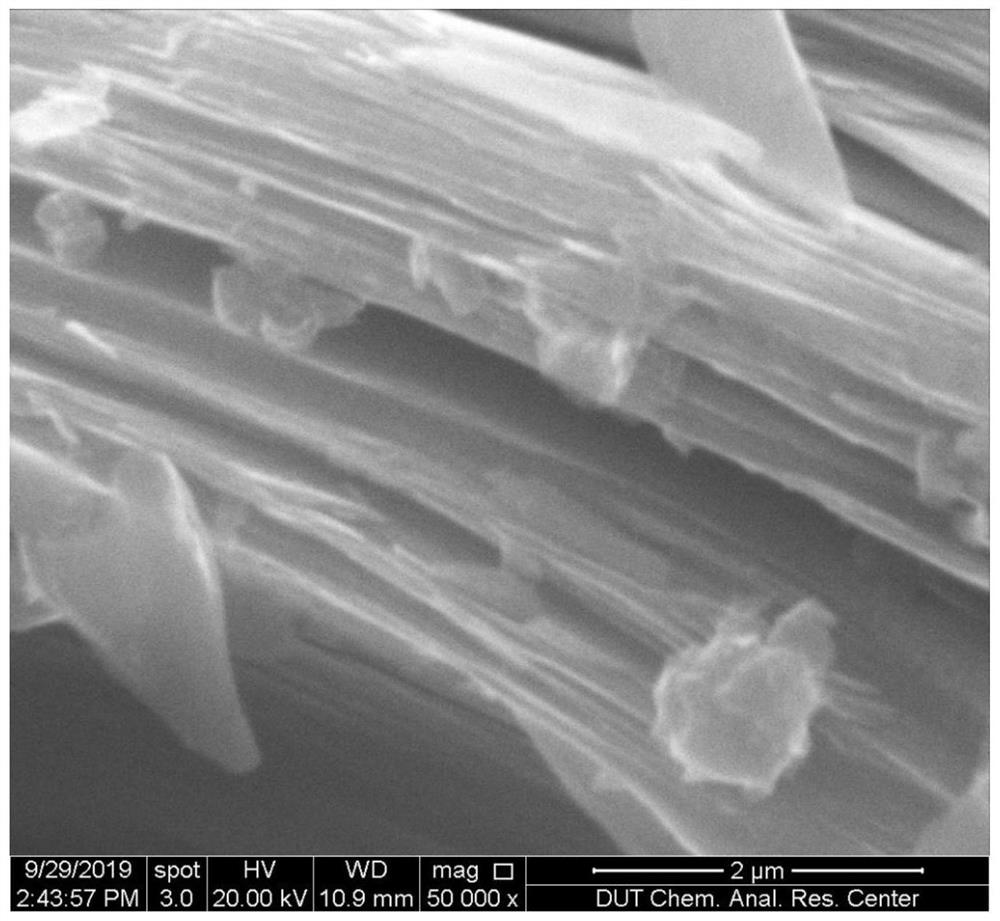

[0033] Step 3: Put the polymer modified coal tar pitch obtained above into a carbonization furnace, raise the temperature to 1100° C. at 0.5° C. / min in an argon atmosphere, and carbonize at high temperature for 2 hours to obtain a polystyrene-modified coal tar pitch-based carbon material. image 3 This is the SEM image of the carbonized pol...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com