Same-floor drainage concentrator without plate descending

A technology of drainage and collectors on the same layer, applied in water supply installations, indoor sanitary pipeline installations, buildings, etc., can solve the problems of large product size requirements, large height space, and the inability of self-contained drainage collectors to improve the performance. The effect of building plane space utilization, reducing the occupation of building plane space, and improving drainage safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

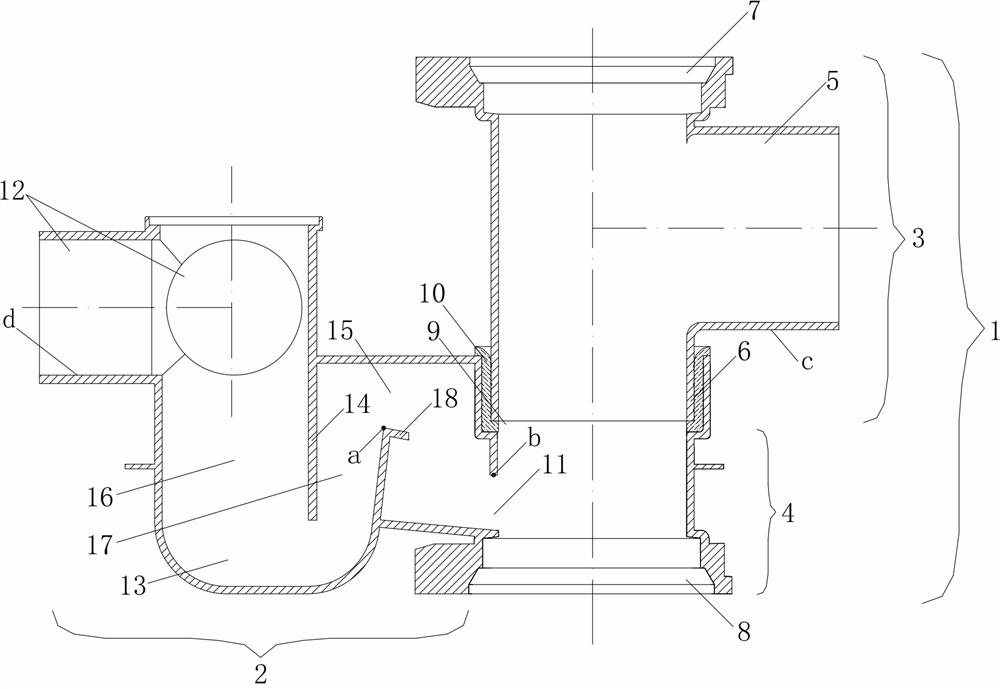

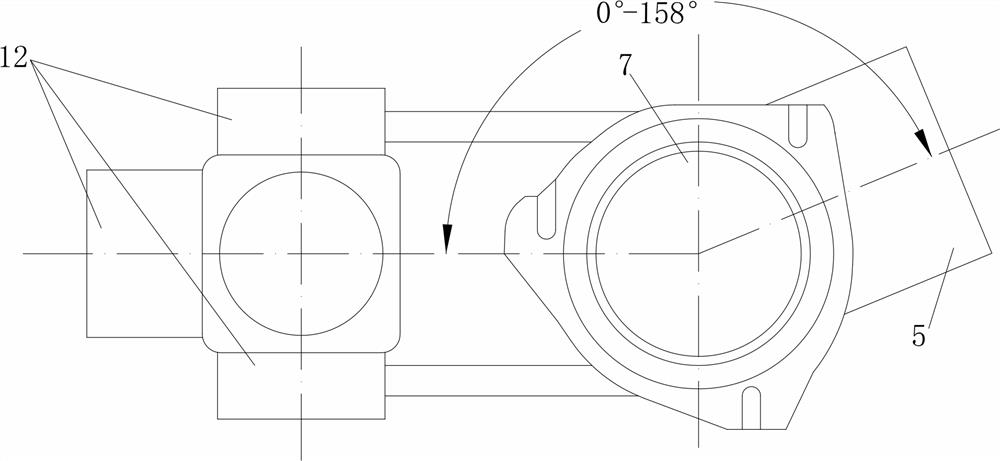

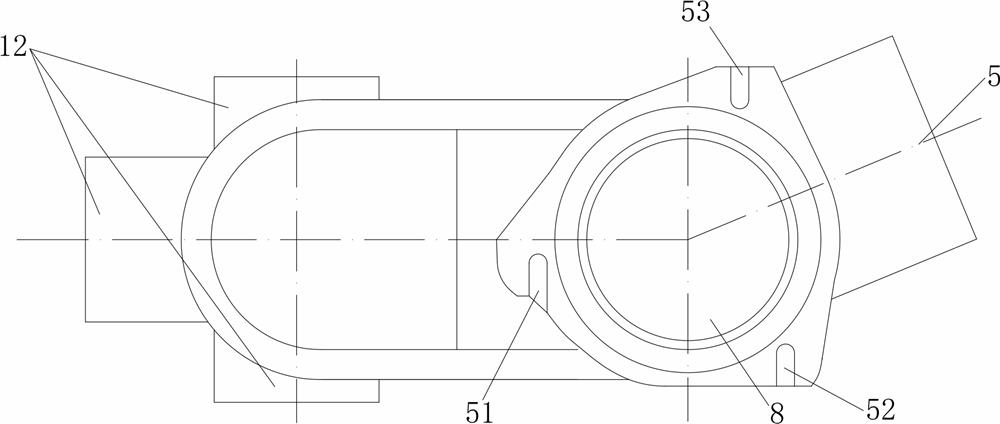

[0040] like figure 1 , 2 , 3, the non-falling board same-floor drainage concentrator according to the present invention is composed of a standpipe drainage connection part 1 and a branch pipe drainage connection part 2. The drainage connection part 1 of the standpipe is connected with the drainage connection part 2 of the branch pipe, and the minimum cross-sectional area of the communication channel is 3000mm 2 , the widest point is 110mm; the riser drainage connection part 1 is connected up and down, and is composed of the sewage drainage connection part 3 and the waste water drainage converging part 4; the sewage drainage connection part 3 is located above the waste water drainage converging part 4. The waste water drainage converging part 4 has a lower port 8 and a communication port 11, and the communication port 11 between the standpipe drainage connection part 1 and the branch pipe drainage connection part 2 is located above the lower port 8 and below the sewage drain...

Embodiment 2

[0042] like Figure 7-10 As shown, the non-falling plate same-floor drainage collector of the present invention is composed of a riser drainage connection part 1 and a branch pipe drainage connection part 2 . The drainage connection part 1 of the standpipe is connected with the drainage connection part 2 of the branch pipe, and the minimum cross-sectional area of the communication channel is 3200mm 2, the widest part is less than 110mm; the riser drainage connection part 1 is connected up and down, and is composed of the sewage drainage connection part 3 and the waste water drainage converging part 4; the sewage drainage connection part 3 is located above the waste water drainage converging part 4. The waste water drainage converging part 4 has a lower port 8 and a communication port 11, and the communication port 11 between the standpipe drainage connection part 1 and the branch pipe drainage connection part 2 is located above the lower port 8 and below the sewage drainage ...

Embodiment 3

[0044] like figure 1 , 2 , 3, and 4, the non-falling board same-floor drainage concentrator according to the present invention is composed of a standpipe drainage connection part 1 and a branch pipe drainage connection part 2. The drainage connection part 1 of the standpipe is connected with the drainage connection part 2 of the branch pipe, and the minimum cross-sectional area of the communication channel is 3200mm 2 , the widest part is less than 110mm; the riser drainage connection part 1 is connected up and down, and is composed of the sewage drainage connection part 3 and the waste water drainage converging part 4; the sewage drainage connection part 3 is located above the waste water drainage converging part 4. The waste water drainage converging part 4 has a lower port 8 and a communication port 11, and the communication port 11 between the standpipe drainage connection part 1 and the branch pipe drainage connection part 2 is located above the lower port 8 and below ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com