Multi-mode precise defrosting start-stop management method and system for air source heat pump

An air source heat pump, multi-mode technology, applied in the heating system, heating method, space heating and ventilation, etc., can solve the problems of the evaporator heat transfer coefficient decline, insufficient heating time, system energy efficiency decline, etc., to achieve stability Running status, improving defrosting accuracy, and improving the effect of accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

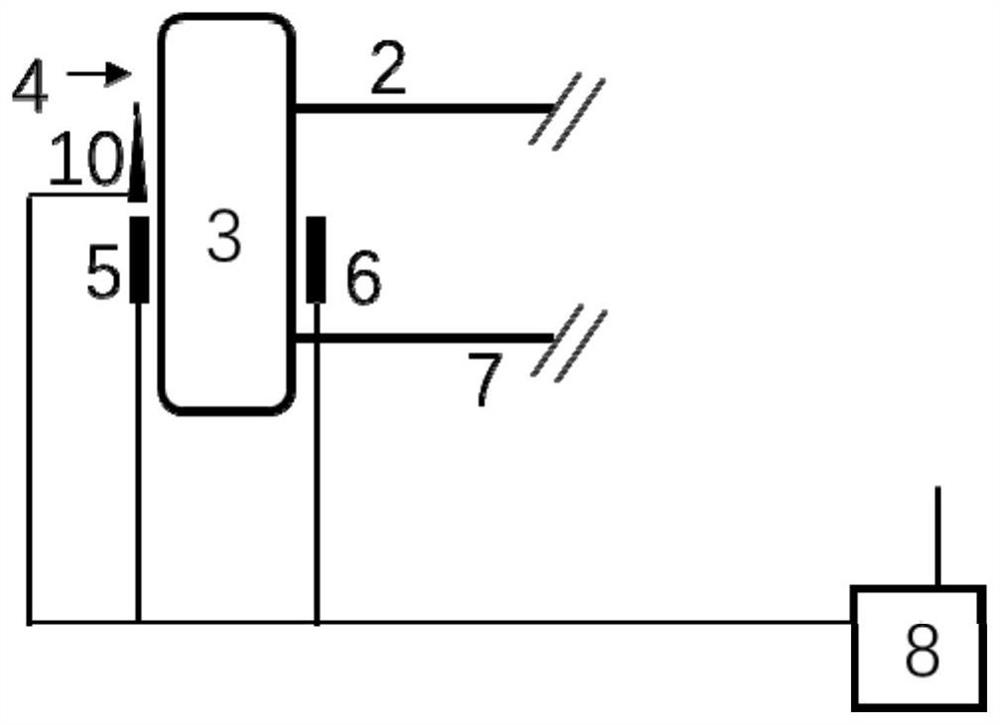

[0050] like figure 1 As shown, the air source heat pump defrosting start-stop management method is applied to an air source heat pump system, including an air source heat pump main body 1, an evaporator 3 and a heating end, and the air source heat pump main body 1 is connected with the working fluid pipelines 2 and 7 through the working fluid pipelines 2 and 7. The evaporator 3 is connected, and the heating end can be provided with a fan coil unit or a heat sink. The inlet side of the evaporator is provided with an inlet temperature sensor 5, and the outlet side is provided with an outlet temperature sensor. Both the inlet temperature sensor 5 and the outlet temperature sensor 5 are connected to the data processing device 8, and the data processing device 8 is connected to the heat pump main body 1 is connected.

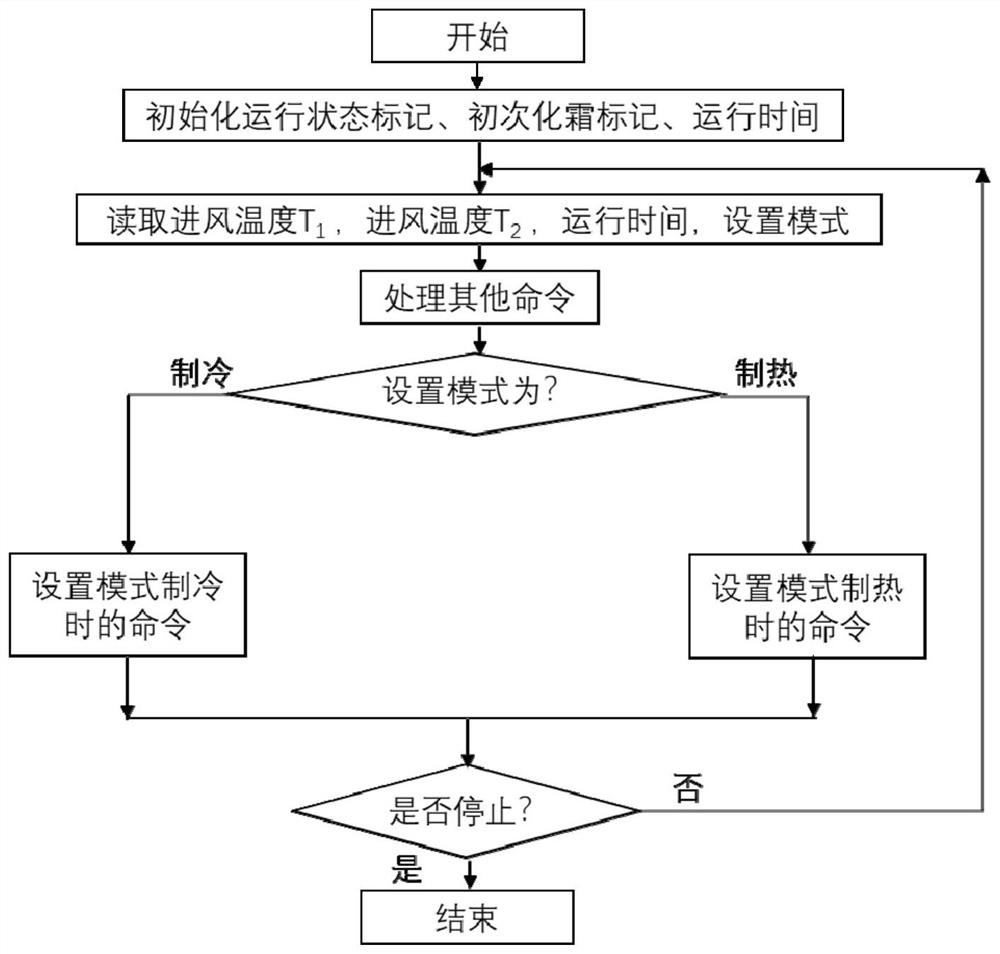

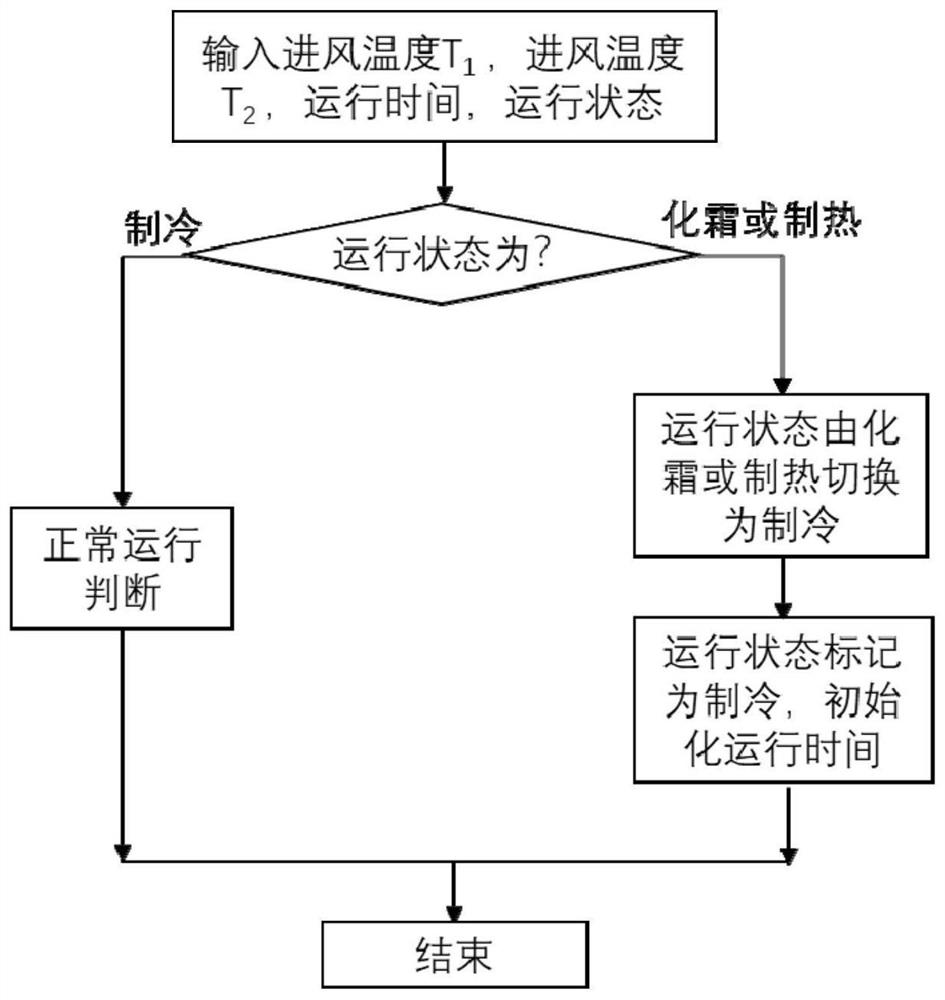

[0051] Before starting the defrosting start-stop management, it is necessary to set the heat pump defrosting operation parameter threshold and the defrosting start ...

Embodiment 2

[0084] The air source heat pump multi-mode precise defrosting start-stop management method described in this embodiment is different from Embodiment 1 in that a tube temperature sensor 9 is also provided at the inlet of the evaporator working fluid pipeline, such as Figure 7 As shown in the figure, the inlet and outlet air temperatures of the auxiliary evaporator jointly determine the defrosting start and stop timing, so as to avoid the problem of inaccurate measurement of the air temperature sensor due to the instantaneous wind force, resulting in the problem of misjudgment of defrosting.

[0085] In step S1, the defrosting operation parameter threshold value further includes the first threshold value T of the inlet pipe temperature of the evaporator. d and evaporator inlet pipe temperature second threshold T e , the initial defrost start conditions also include the evaporator inlet pipe temperature T 7

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com