A cable core recovery separator

A separator and cable core technology, applied in the field of cable core recovery separators, can solve the problems of cumbersome and slow cables

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

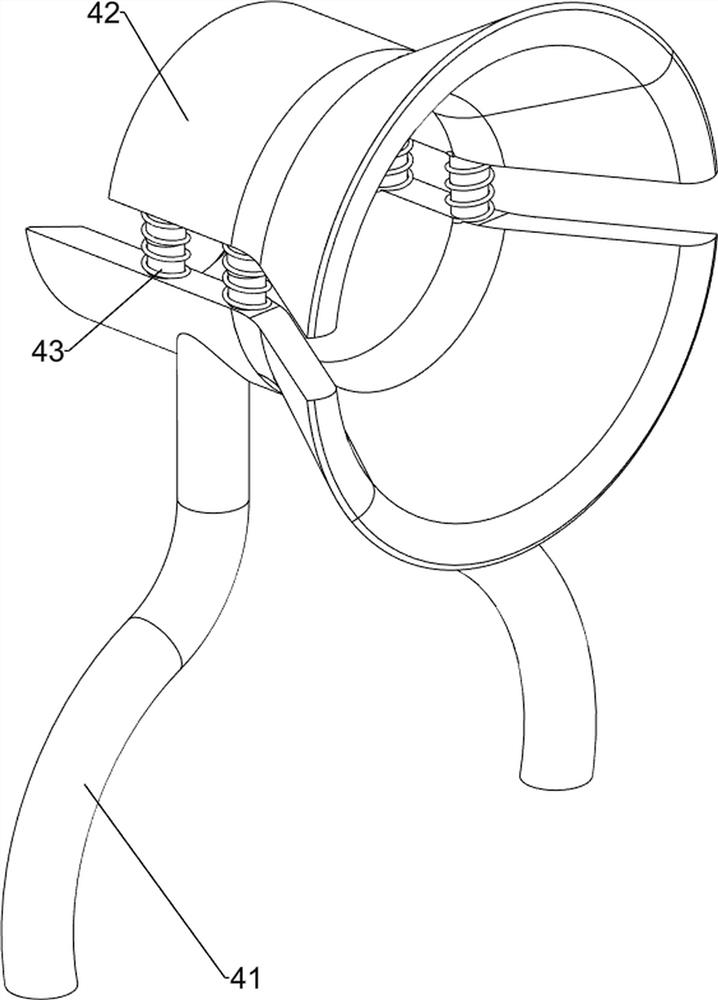

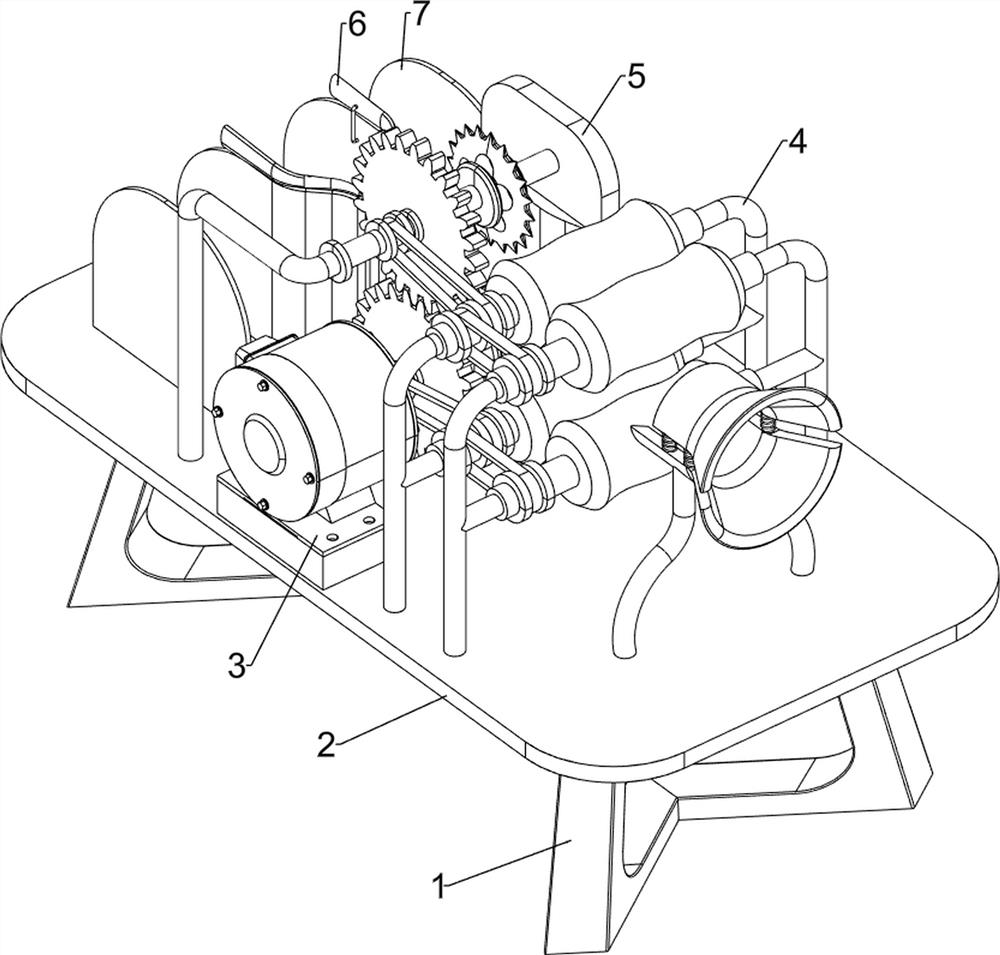

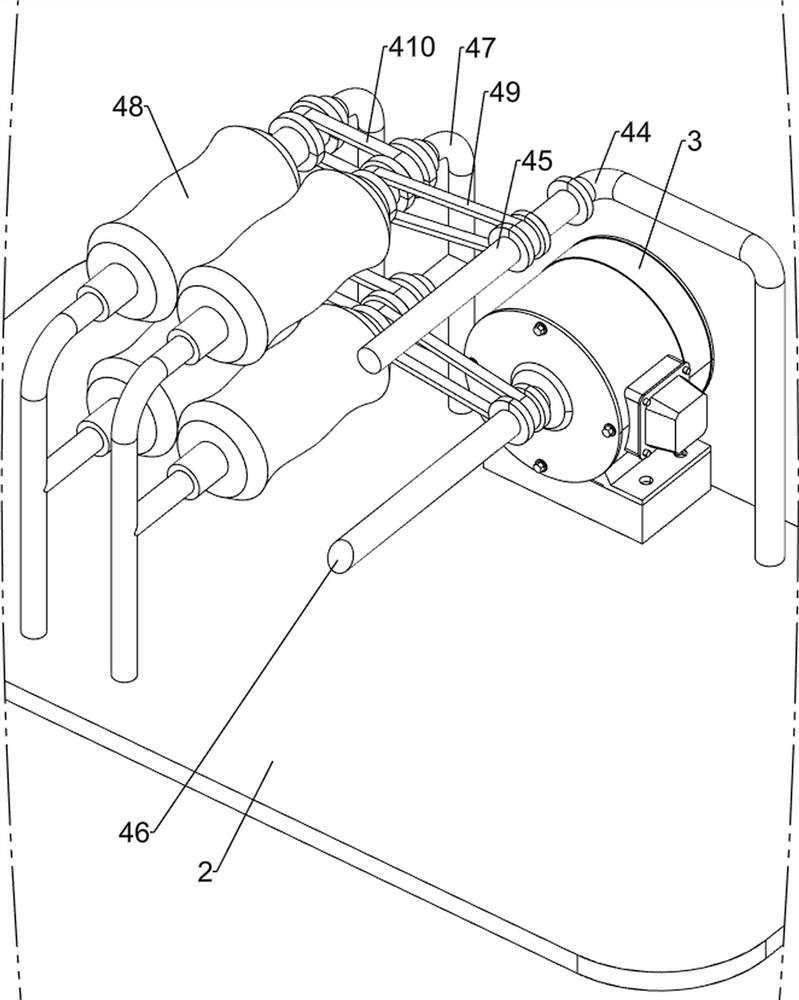

[0022] A cable core recovery separator, such as Figure 1-5 As shown, it includes a fixed bracket 1, a worktable 2, a motor 3, a transmission mechanism 4 and a cutting mechanism 5. The fixed bracket 1 is provided with a worktable 2, a motor 3 is installed on the front side of the top of the worktable 2, and a right side of the top of the worktable 2 is installed. A transmission mechanism 4 is provided on the side, and a cutting mechanism 5 is provided in the middle of the top side of the worktable 2 , and the cutting mechanism 5 cooperates with the transmission mechanism 4 .

[0023] Waste cables are harmful to the social environment and need to be recycled for a second time. However, the process of manually separating cables is cumbersome and complicated, and the separation speed is slow. This equipment can reduce the burden on workers. First, people insert the cables into the transmission mechanism 4, and then start the motor. 3. The rotation of the output shaft of the motor...

Embodiment 2

[0029] On the basis of Example 1, as figure 1 and Figure 5 As shown, it also includes a separation column 6 and a transmission isolation plate 7 , a transmission isolation plate 7 is symmetrically arranged on the left side of the top of the workbench 2 , and a separation column 6 is arranged on the inner top of the transmission isolation plate 7 .

[0030]After people insert the cable, start the motor 3, and when the cable starts to be divided, the separation columns 6 on the front and rear sides are inserted into the front and rear sides of the cable respectively. The inner cores are separated, the cable shell falls into the two transmission isolation plates 7, and the cable inner core falls between the two transmission isolation plates 7. If people still need to cut and separate the cables, they can continue to insert the cables. The motor 3 can be turned off for cutting. After the cutting knife 53 stops moving, people collect the cable cores. If the device needs to be use...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com