Direct type panel lamp

A panel lamp, direct type technology, which is applied in the direction of flat light source, cooling/heating device of lighting device, lighting and heating equipment, etc., can solve the problems of high price of light guide plate and high production cost of panel lamp, and achieve high cost performance and heat dissipation effect. Good, good irradiation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The application will be described in further detail below in conjunction with the accompanying drawings.

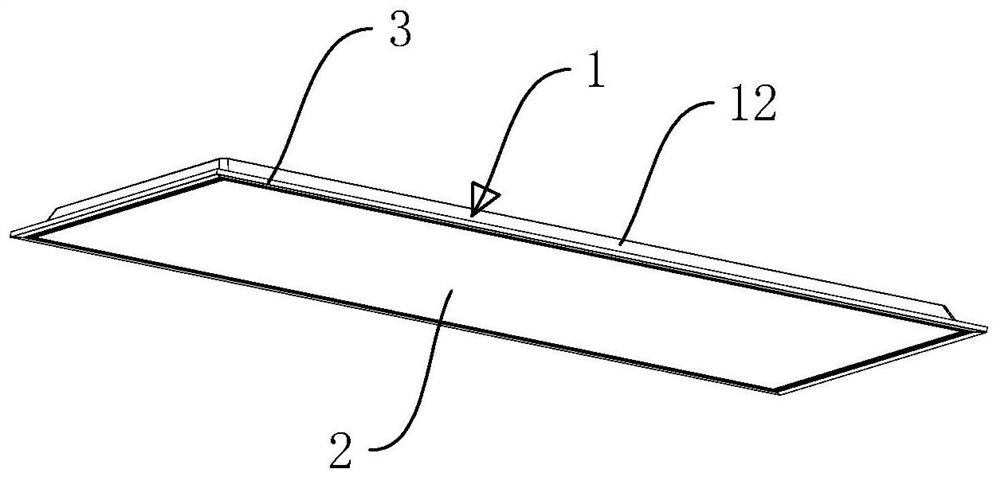

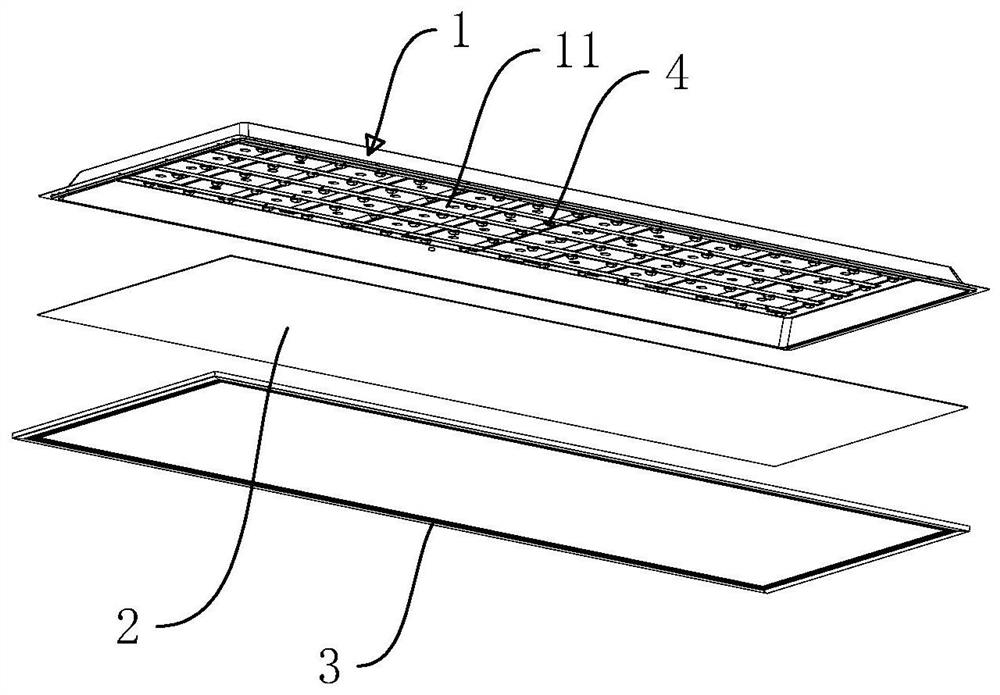

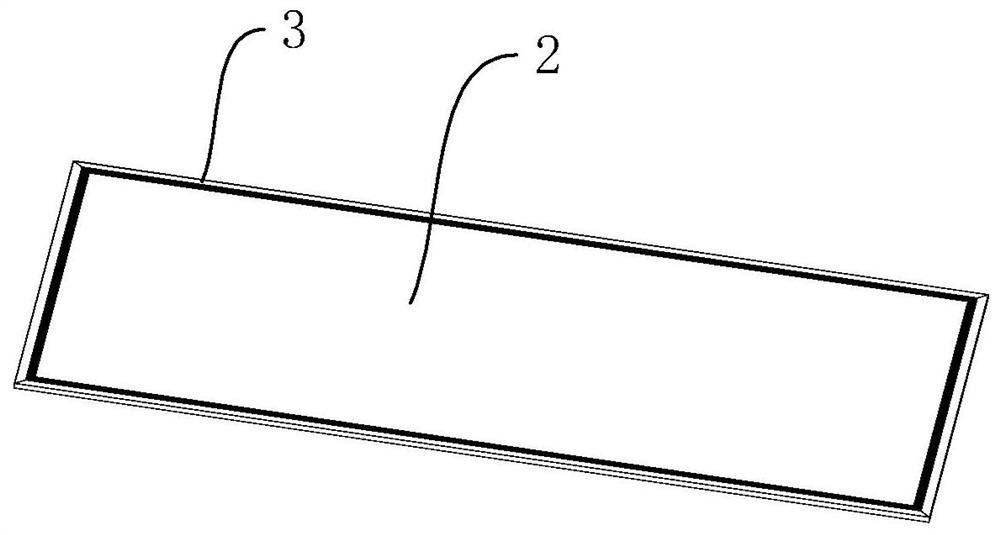

[0033] refer to figure 1 and figure 2 , the embodiment of the present application discloses a direct type panel light, which includes an installation housing 1, a rectangular diffuser plate 2, a rectangular fixed frame 3 and a light source. The mounting shell 1 includes a mounting plate 11 and four bent plates 12 disposed on the outer periphery of the mounting plate 11 and bent downward relative to the mounting plate 11 . The mounting plate 11 is a rectangular plate, and the bending plate 12 is a trapezoidal plate. Each bending plate 12 and the mounting plate 11 form a mounting cavity with an opening at the lower end, and the opening of the mounting cavity is flared. The fixing frame 3 fixes and blocks the diffuser plate 2 at the opening of the installation cavity.

[0034] refer to image 3 and Figure 4 , the mounting plate 11 is provided with a sinking gro...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com