Method for producing tray for storing aneurysm clips, and tray for storing aneurysm clips

A technology for aneurysm clips and trays, which is applied in the manufacture of tools, wound clips, medical science, etc., can solve the problems of high cost and troublesome tray manufacturing, and achieve the effect of easy disinfection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

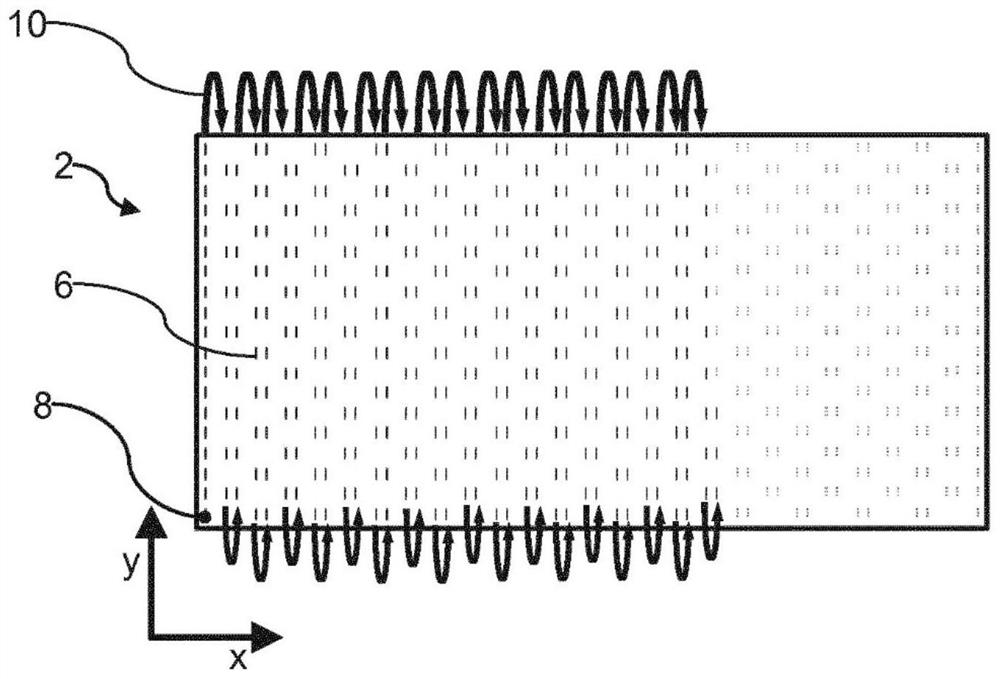

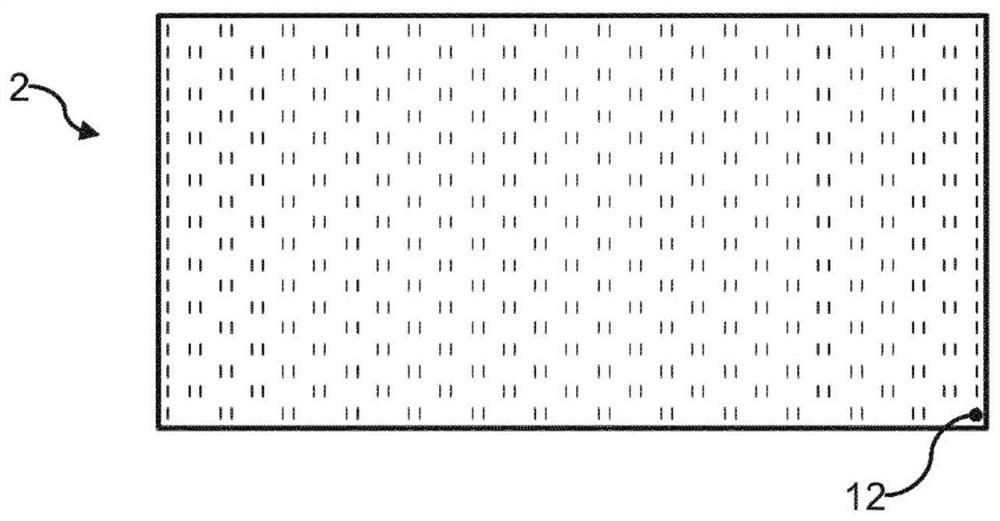

[0038] figure 1 is a plan view of a metal plate 2 with a substantially rectangular outline. In order to provide the plate 2 with a perforation 4 (see Figure 5 ), the first edge or interface 6 of the perforation 4 is first cut into the plate 2 by means of a (not shown) laser (see figure 2 and 3). A common feature of the first interfaces 6 is that they all extend in one direction y. In order to cut the first interface 6 as efficiently as possible, the laser cutting is started at the starting point 8 in the corner of the sheet 2 and the laser is controlled by pulsed to cut each first interface 6 .

[0039] After all of the first interface 6 has been cut and the laser is positioned at the intermediate point 12, the second edge or interface 14 is cut. A common feature of the second interfaces 14 is that these interfaces all extend along a direction x perpendicular to the direction y. Starting from an intermediate point 12 , which is likewise located in a corner of the shee...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com