Mirror with double-damping structure and implementation method thereof

A damping structure and mirror technology, which is applied in the field of mirrors, can solve problems such as uneven strength, wear and tear of lifting rods, and jamming, and achieve the effect of reducing light loss and solving rotation jamming

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

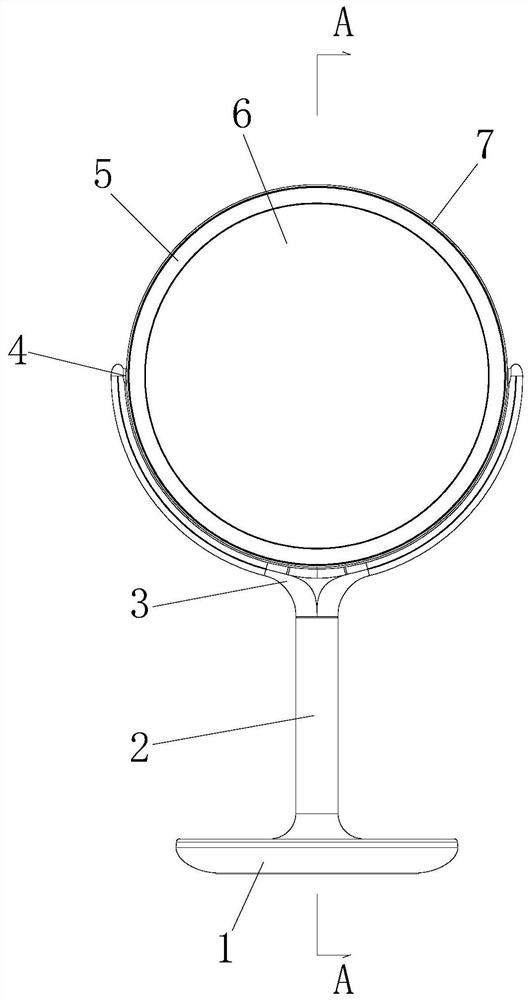

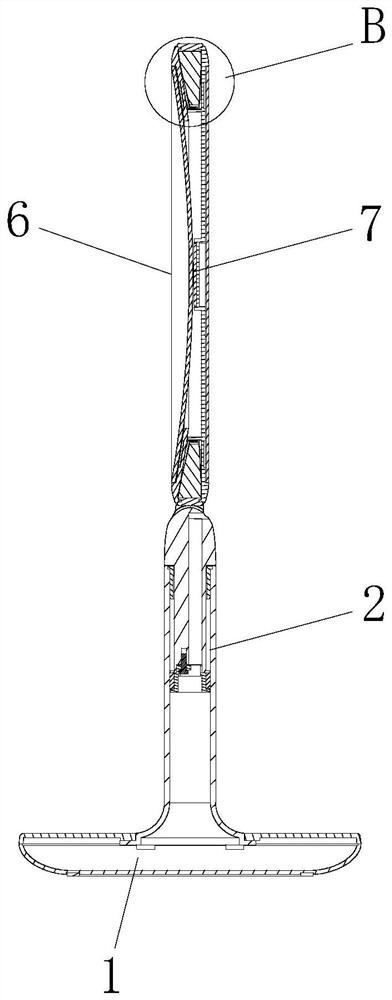

[0040] see Figure 1-7 , the present invention provides the following technical solutions: a mirror with a double damping structure, including a mirror base 1, a lifting damping rod 2 is connected above the mirror base 1, a bracket 3 is connected above the lifting damping rod 2, and the upper end of the bracket 3 passes through The rotating damping shaft 4 is connected with a mirror frame 7, the front surface of the mirror frame 7 is connected with a lens 6, and the circumference of the mirror frame 7 is provided with a light-emitting mirror 5;

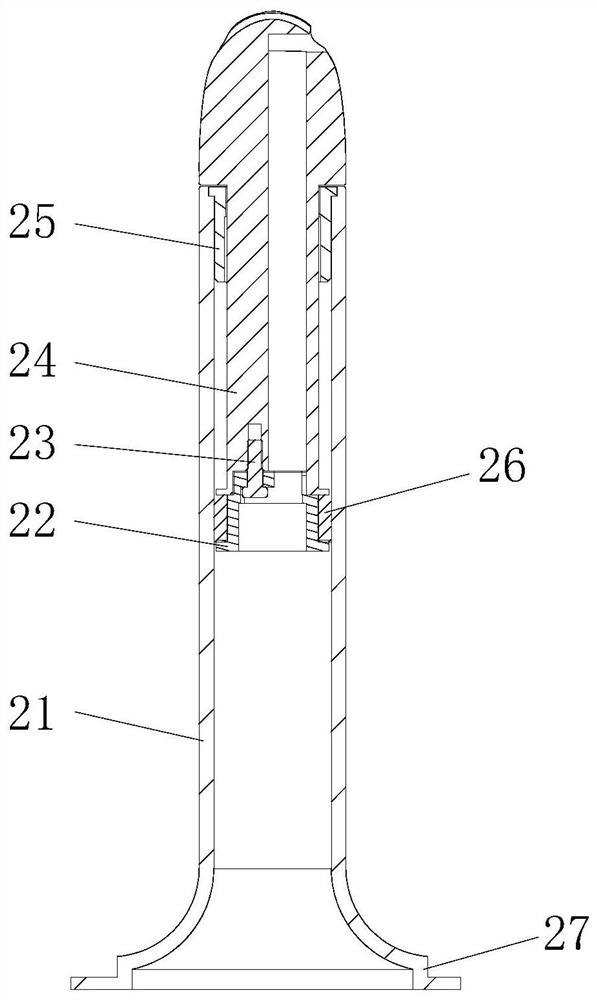

[0041] Further, the lifting damping rod 2 includes a sleeve 21, and the inside of the sleeve 21 is embedded with a lifting rod 24. The bottom of the lifting rod 24 is connected with a lower hanging buckle 22, and the lower hanging buckle 22 and the lifting rod 24 are connected by a screw 23. A friction block 26 is sheathed on the circumference of the lower hanging buckle 22 , and an upper stopper 25 is connected to the upper end of th...

Embodiment 2

[0047] The difference between this embodiment and Embodiment 1 is that further, the rotary damping shaft 4 includes a shaft bracket 41, on which a rotation bracket 45 is rotatably connected, and a washer 44 is provided on one side of the rotation bracket 45, and the washer 44 is far away from the rotation One side of the bracket 45 is provided with a nut 43 , and the nut 43 is engaged with the shaft bracket 41 through thread engagement.

[0048] By adopting the above technical solution, the force during rotation can be adjusted by adjusting the tightness of the nut 43, so that the lens 6 can be stably stationary at any angle.

[0049] Further, the washer 44 is a nylon member, and damping oil is applied between the washer 44 and the rotating bracket 45 .

[0050] By adopting the above technical solution, the gasket made of nylon itself is a friction-resistant material and has a self-lubricating effect on the surface, which can play a good role in friction resistance and damping...

Embodiment 3

[0054] The difference between this embodiment and Embodiment 1 is that further, the light-emitting mirror 5 includes a light guide mirror 8 and an LED light source 9, wherein the LED light source 9 is arranged inside the circumference of the mirror frame 7, and the light guide mirror 8 is arranged on the LED light source. 9 outside.

[0055] Further, the light guide mirror 8 includes a light entrance surface 81 and a light exit surface 82, wherein the inner circle of the light guide mirror 8 is the light entrance surface 81, the side surface of the light guide mirror 8 circumference is the light exit surface 82, and the light guide mirror 8 is transparent Acrylic components, and the light guide mirror 8 is provided with white paint on the sides except the light entrance surface 81 and the light exit surface 82, and the light entrance surface 81 and the light exit surface 82 are both high-gloss surfaces.

[0056] By adopting the above-mentioned technical scheme, the light emitt...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com