Car body and rail vehicle of a drum car

A drum-shaped vehicle and vehicle body technology, which is applied in the field of rail vehicles, can solve the problems of large bulge in the vertical direction, increase the space of the waist, and difficulty in processing and manufacturing, so as to achieve loose space, easy processing and manufacturing, and simple structure Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

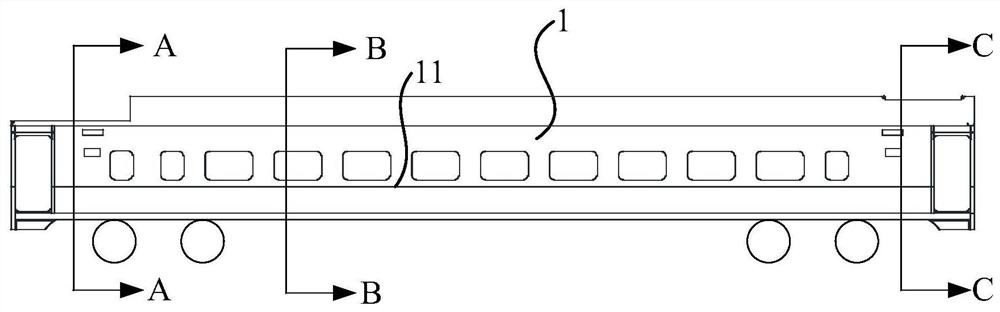

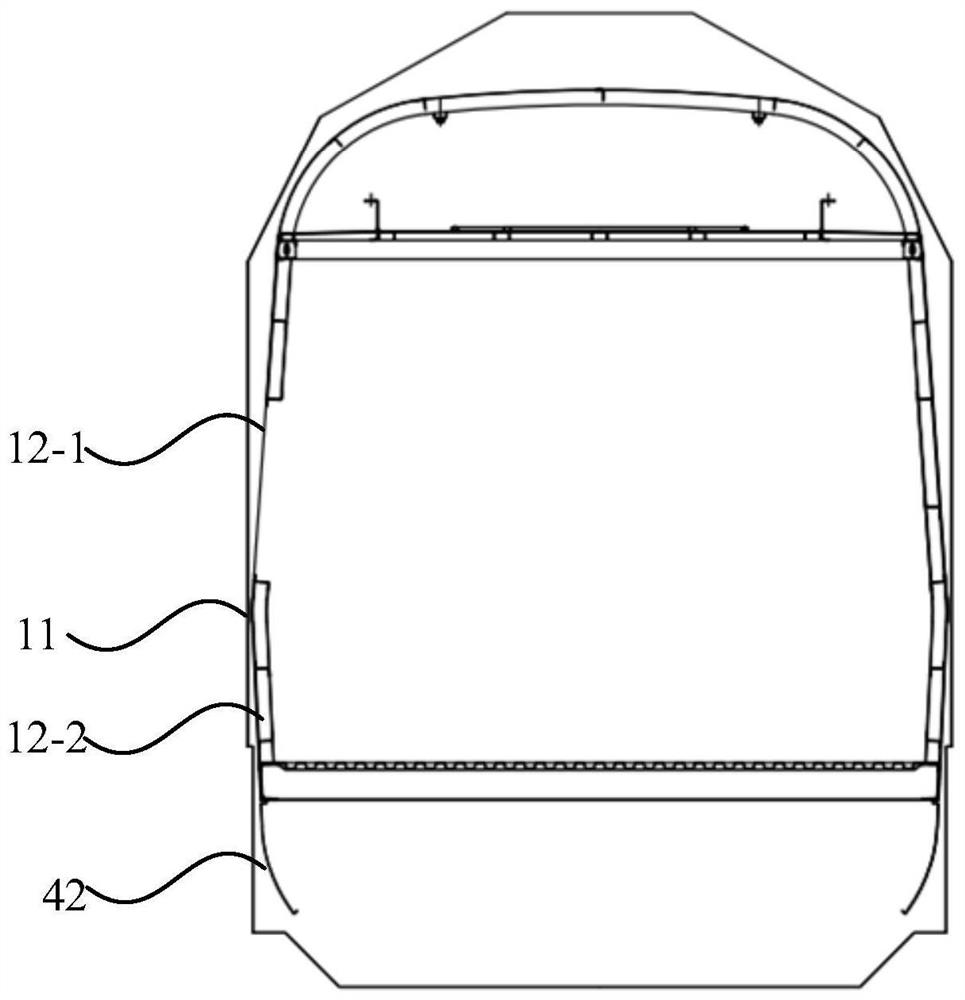

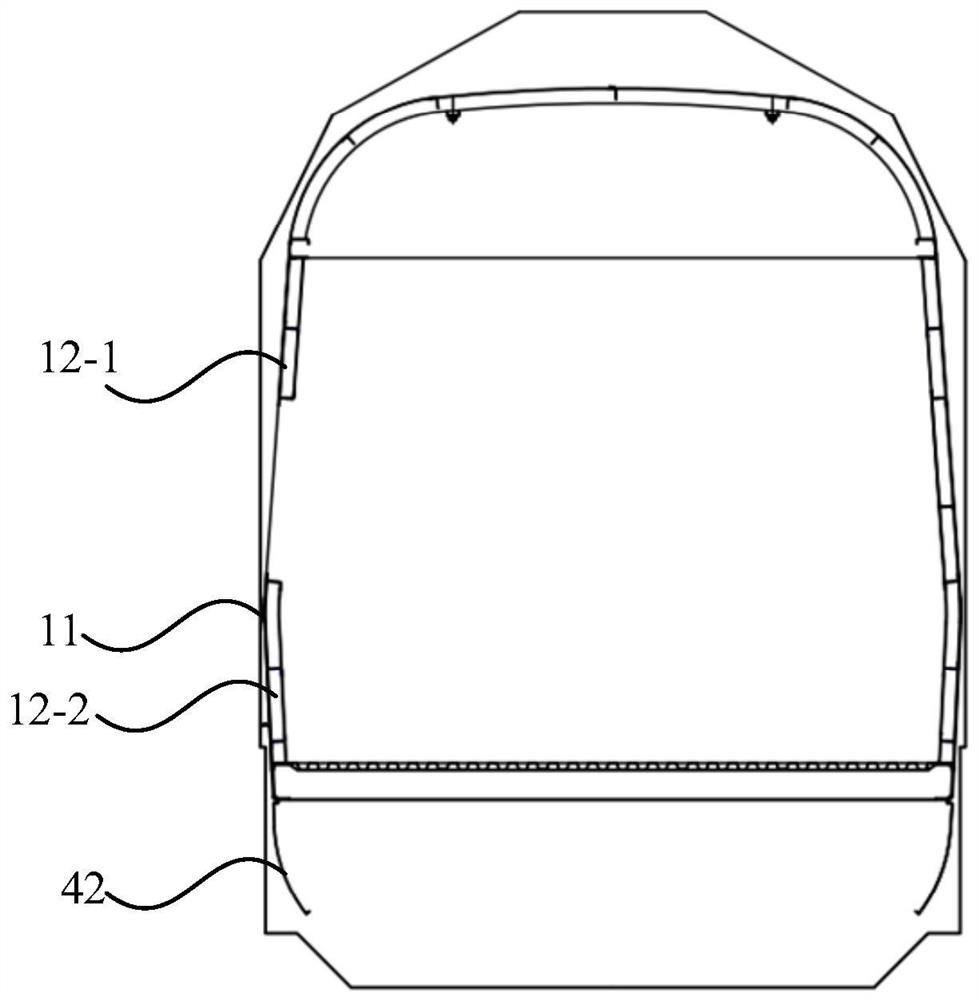

[0059] Such as figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 with Image 6 As shown, the car body of the drum-shaped car of the embodiment of the present application includes a side wall 1, and the side wall 1 includes:

[0060]Recessed part 11, described recessed part 11 is recessed in described car body and protrudes outside described car body, and the opening of described recessed part 11 faces described car body, and the height of described recessed part 11 is above described side wall Below the lower edge of the window; wherein, the recessed portion 11 is used to accommodate the elbow of the passenger sitting on the seat;

[0061] An upwardly inclined flat portion 12-1, the lower edge of the upwardly inclined flat portion 12-1 is fixed to the upper edge of the recessed portion 11, and the upwardly inclined flat portion is inclined toward the vehicle body;

[0062] A downwardly inclined flat portion 12-2, the upper edge of the downwardly inclined flat porti...

Embodiment 2

[0133] The body of the drum-shaped vehicle in the embodiment of the present application has the following characteristics on the basis of the first embodiment.

[0134] Figure 4 for figure 1 The C-C sectional view of the above is a sectional view of the car body at the position where the water tank is installed, and a water tank movable roof structure is arranged at the position where the water tank is installed.

[0135] Figure 22 Shown in is a top view structural diagram of a water tank movable roof structure provided by an embodiment of the present application;

[0136] Figure 23 shown in Figure 22 A-A sectional view of ; Figure 24 shown in Figure 23 Partial enlarged view of part A in the middle; Figure 25 shown in Figure 22 B-B sectional view; please refer to Figure 22-Figure 25 .

[0137] This embodiment provides a water tank movable roof structure 300, which is adapted to the water tank openings on the compartment roof 410 and the side roof 420, and is...

Embodiment 3

[0156] This embodiment provides a compartment, which includes a roof and a side roof, the roof and the side roof are provided with a water tank opening, and the water tank opening is provided with the movable roof structure of the water tank as described in the first embodiment above.

[0157] Since the compartment of this embodiment adopts the movable roof structure of the water tank described in the first embodiment above, the outer contour of the movable roof and the outer contour of the top plate are located in the same plane or arc surface, which is beneficial to reduce the resistance when the vehicle is running , to reduce the energy consumption of vehicle operation, and at the same time, it is also conducive to reducing the noise generated when the vehicle is running at high speed, and improving the passenger experience.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com