A self-resetting shear-constrained buckling type damage controllable assembled beam-column joint

A technique for constraining buckling, beam-column joints, applied to building types, protected buildings/shelters, buildings, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

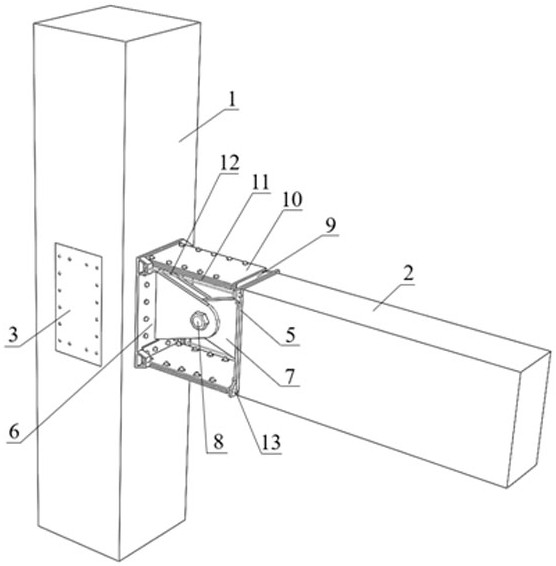

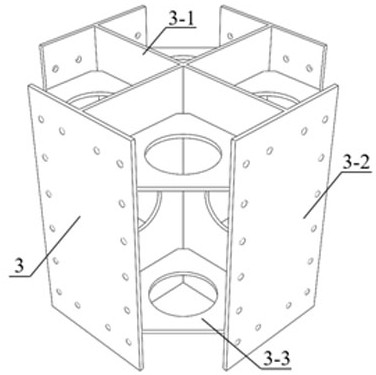

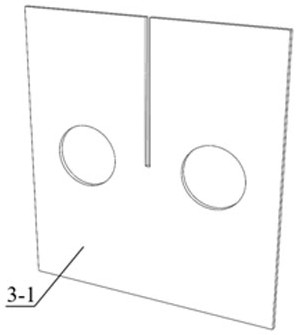

[0015] like Figure 1 ~ 10 , The present invention is a self-resetting Shear - constrained controlled flexion injury column Joint assembly, comprising prefabricated columns 1, prefabricated beams 2, pin 8, shearing - bending plate 9 and the elastic member 12, bis 3 comprises a steel drum -shaped web 3-1, 3-2 stiffening flange plate 3-3, the preform embedded within a core region 1 column-shaped duplex steel cylinder 3, at the ends of the beam preform 2 4 embedded steel anchor, the anchoring steel beam end portion 4 welded beam end plate 5; double T flanges of the post web first riser 6-1 and duplex steel cylinder shaped 3- 2 secured by bolts, the T-beam web a second riser 7-1 and the beam end plate 5 is secured by a bolt, the T-shaped posts double web plate first lug and the beam T 6-2 the second plate-shaped connection plate lug is connected by a pin 8 hinged 7-2; the shear - buckling restraint plate 9 by a bolt 10 between the first and the second constraint plate binding plate 11,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com