Self-resetting shearing-constrained buckling damage-controllable fabricated beam-column joint

A technology to constrain buckling and beam-column joints, applied in building types, protected buildings/shelters, building components, etc., to achieve the effects of reducing residual deformation, easy disassembly and replacement, and easy guarantee of joint connection quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

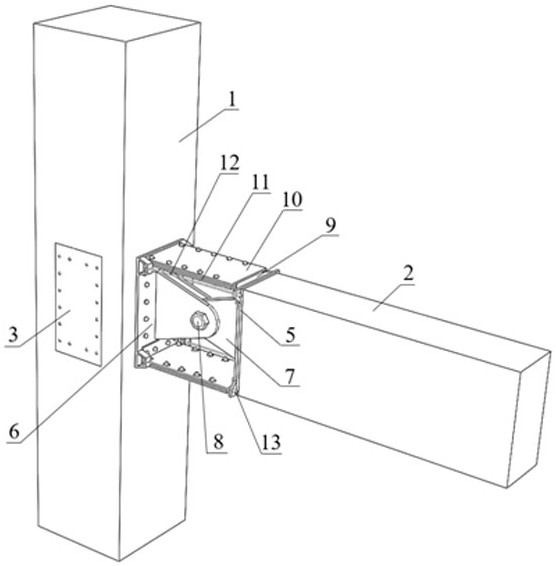

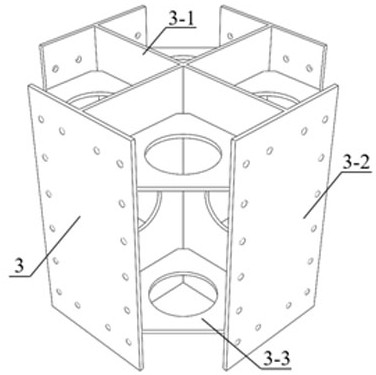

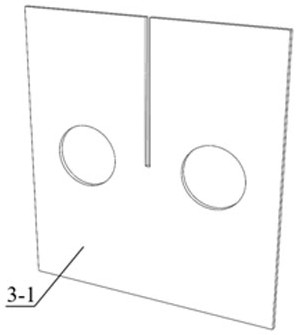

[0015] Such as Figure 1 to Figure 10 As shown, the present invention is a self-resetting shear-constrained buckling type damage-controllable assembled beam-column joint, including a prefabricated column 1, a prefabricated beam 2, a pin 8, a shear-buckling plate 9 and an elastic member 12, double The I-shaped steel cylinder 3 includes a web 3-1, a flange 3-2 and a stiffening plate 3-3. The prefabricated column 1 pre-embeds a double I-shaped steel cylinder 3 in the core area, and the prefabricated beam 2 is at the end Pre-embed the anchoring section steel 4, the anchoring section steel 4 is welded to the beam end plate 5 at the end of the beam; the first vertical plate 6-1 of the double T-shaped connecting plate of the column and the flange 3-1 of the double I-shaped steel cylinder 2 through bolts, the second vertical plate 7-1 of the beam T-shaped connecting plate and the beam end plate 5 are fixed through bolts, and the first ear plate 6-2 of the column double T-shaped connec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com