Inward mouth folding device for bag body

A bag body and folding technology, which is applied in the field of automatic production equipment for bag bodies, can solve the problems of time-consuming, labor-intensive, and time-consuming production processes for manual folding and sewing, and saves time and labor costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The technical means adopted by the present invention to achieve the intended creation purpose are further described below in conjunction with the accompanying drawings and preferred embodiments of the present invention.

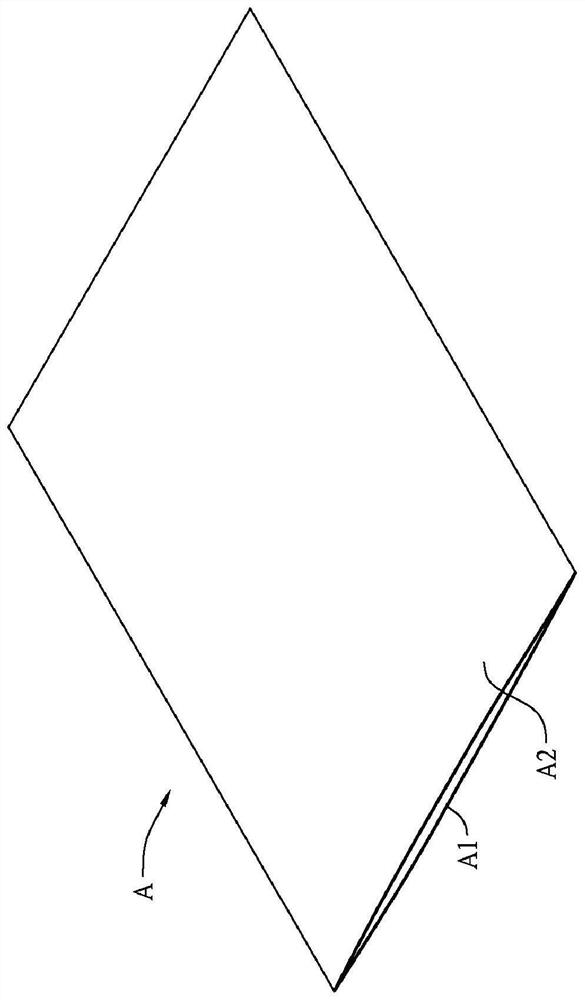

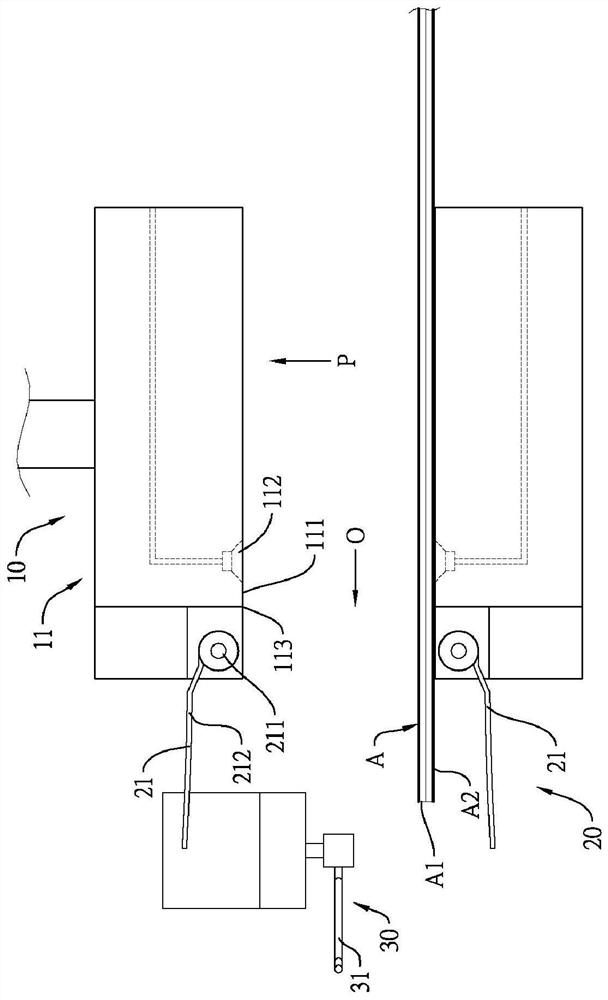

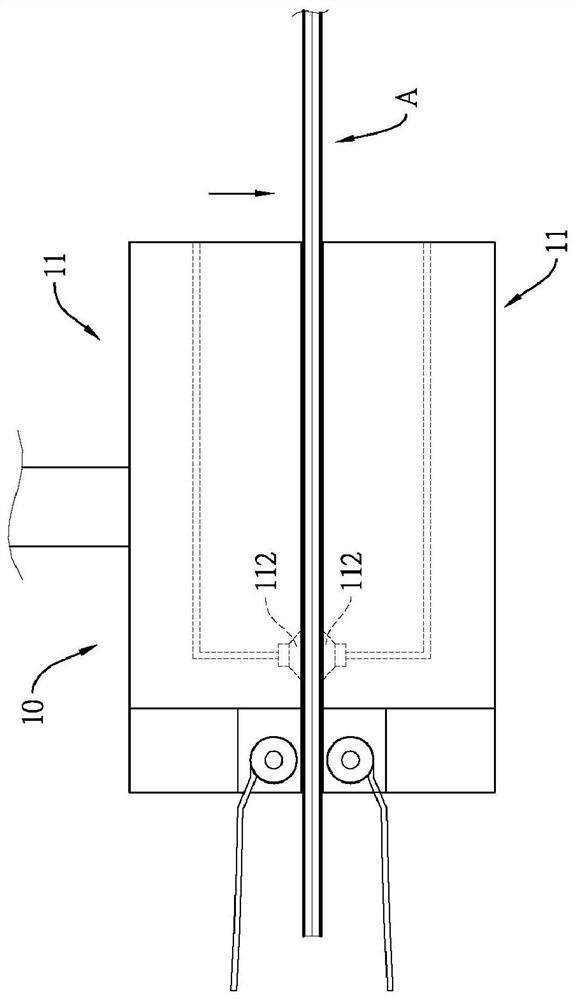

[0030] see figure 2 , Figure 6 and Figure 8 As shown, the folding device in the bag of the present invention is used to make a bag body A made of a flat plastic material (such as figure 1 As shown) the cutting opening A1 and the folding portion A2 adjacent to the periphery of the cutting opening A1 are folded toward the inside of the bag body A together, and in this embodiment can be further folded inward to the folding portion inside the bag body A A2 is welded and fixed on the inner wall surface of the bag body A (the state where the folded part A2 is welded and fixed is as follows: Figure 10 shown), the bag body A is preferably a plastic woven bag; the folding device in the bag includes a bag opening mechanism 10, a first folding assembly 20 ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap