High-altitude LED lamp automatic replacement method

A technology of LED lamps and LED lamps, which is applied to the loss prevention measures of lighting devices, lighting and heating equipment, testing of machinery/structural components, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

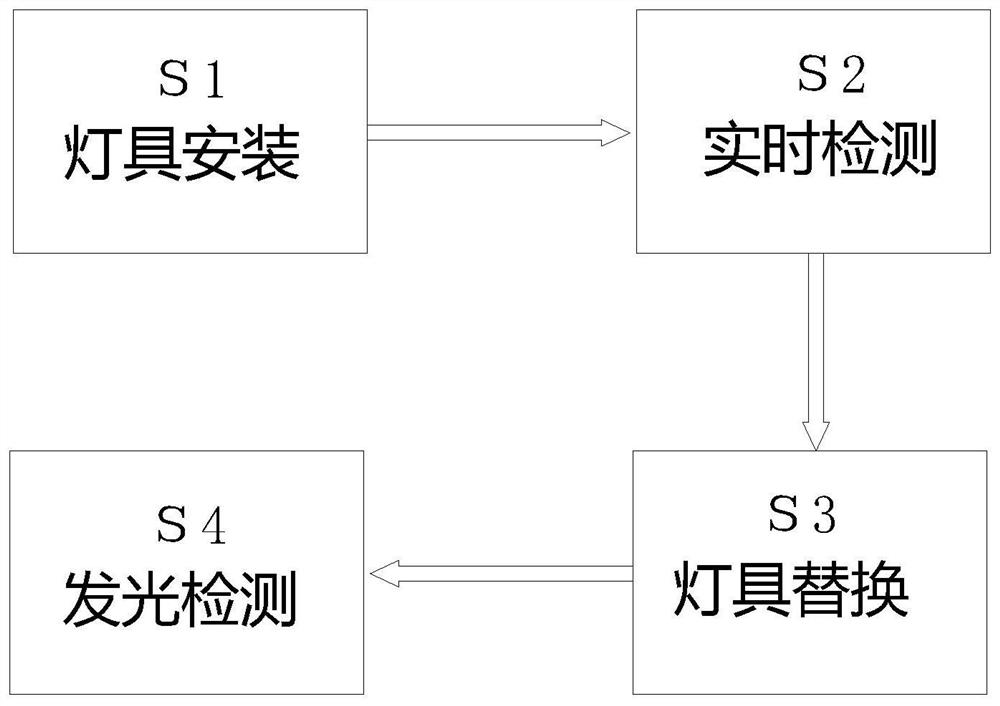

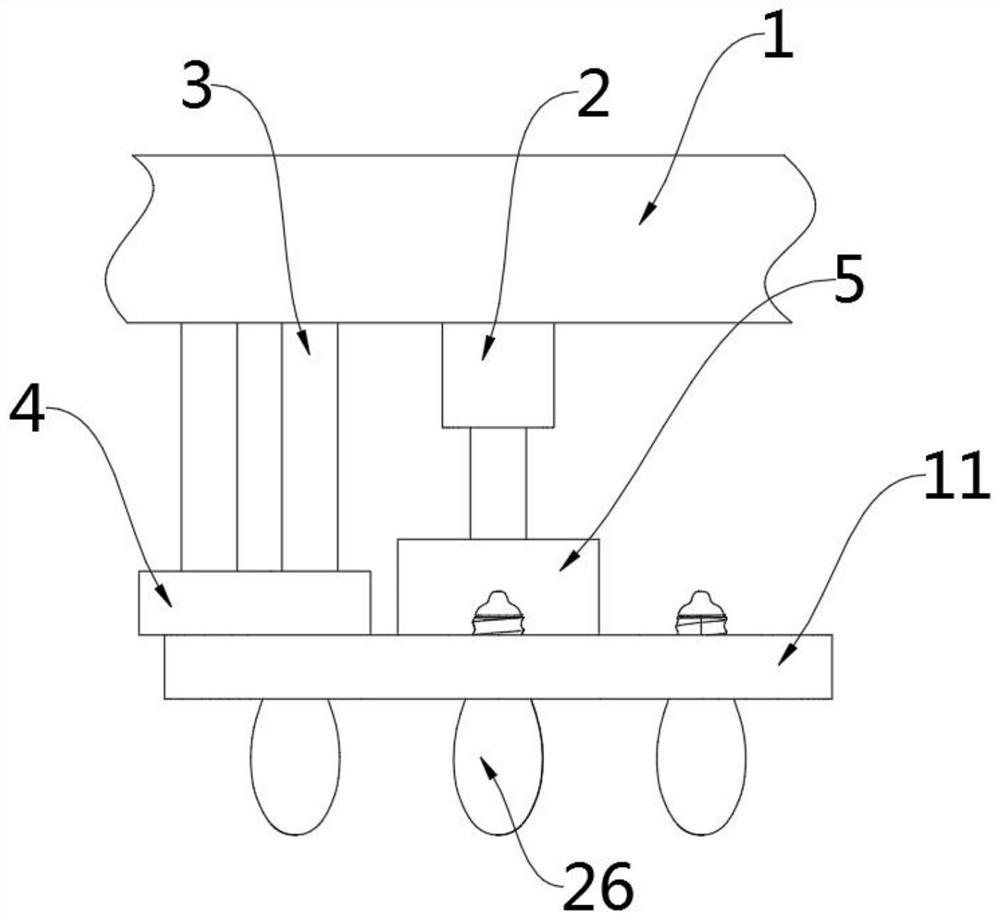

[0046] see Figure 1-9 , according to a method for automatic replacement of high-altitude LED lamps according to an embodiment of the present invention,

[0047] S1. Lamp installation: When installing, first prepare multiple LED lamps, one of which is used as the main light-emitting lamp, and the other ones are used as spare lamps, and the prepared multiple LED lamps are installed and fixed in the high altitude in a certain order On the automatic replacement device of LED lamps;

[0048] S2. Real-time detection: through the high-altitude LED lamp automatic replacement device, one of the main light-emitting lamps is monitored and detected in real time at night;

[0049] S3. Replacement of lamps: When the high-altitude LED lamp automatic replacement device in step S2 detects that the main light-emitting lamp is not on at night, the main light-emitting lamp is removed by the high-altitude LED lamp automatic replacement device, and the one prepared in step S1 is replaced. Other ...

Embodiment 2

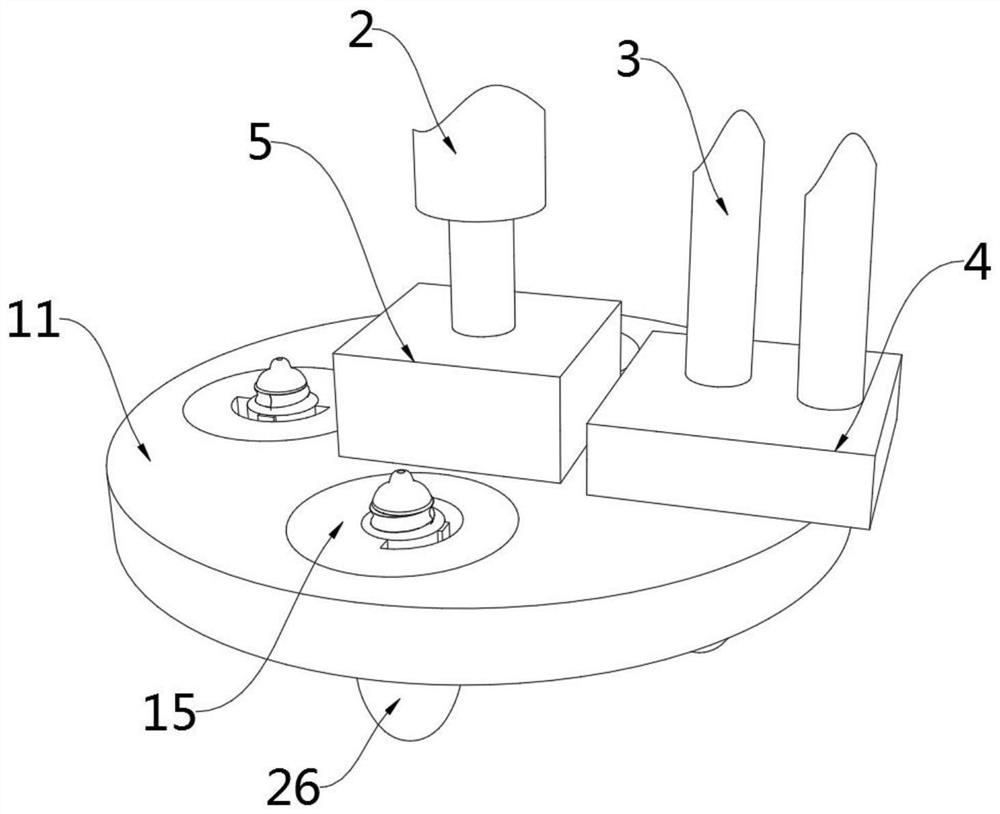

[0066] see Figure 1-7 A first buffer pad 23 is fixed on the side of the push plate 22 away from the rotating shaft 21, a second buffer pad 30 is fixed on the side of the limit groove 24 away from the third motor 18, and the first buffer pad 23 and the second buffer pad The pads 30 are non-slip rubber pads, and the inside of the limit block 19 is provided with a limit hole. The volume of the limit hole matches the volume of the limit rod 20, and the limit rod 20 slides inside the limit block 19 through the limit hole. Connection, the peripheral side of the LED lamp 26 is fixed with a reinforcing column 28, and the volume of the limiting groove 24 matches the volume of the reinforcing column 28, the volume of the chute 27 matches the volume of the second worm wheel 25, and the second worm wheel 25 Through the chute 27, the rotating disk 11 is internally rotated and connected, and the side of the push plate 22 near the first buffer pad 23 is provided with an arc-shaped groove, a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com