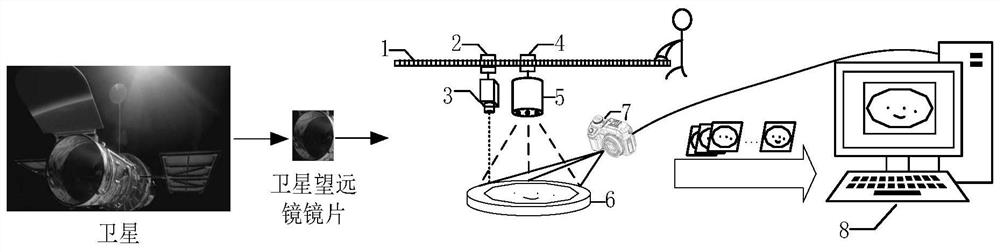

A system and method for detecting the surface defect contour of a satellite telescope lens

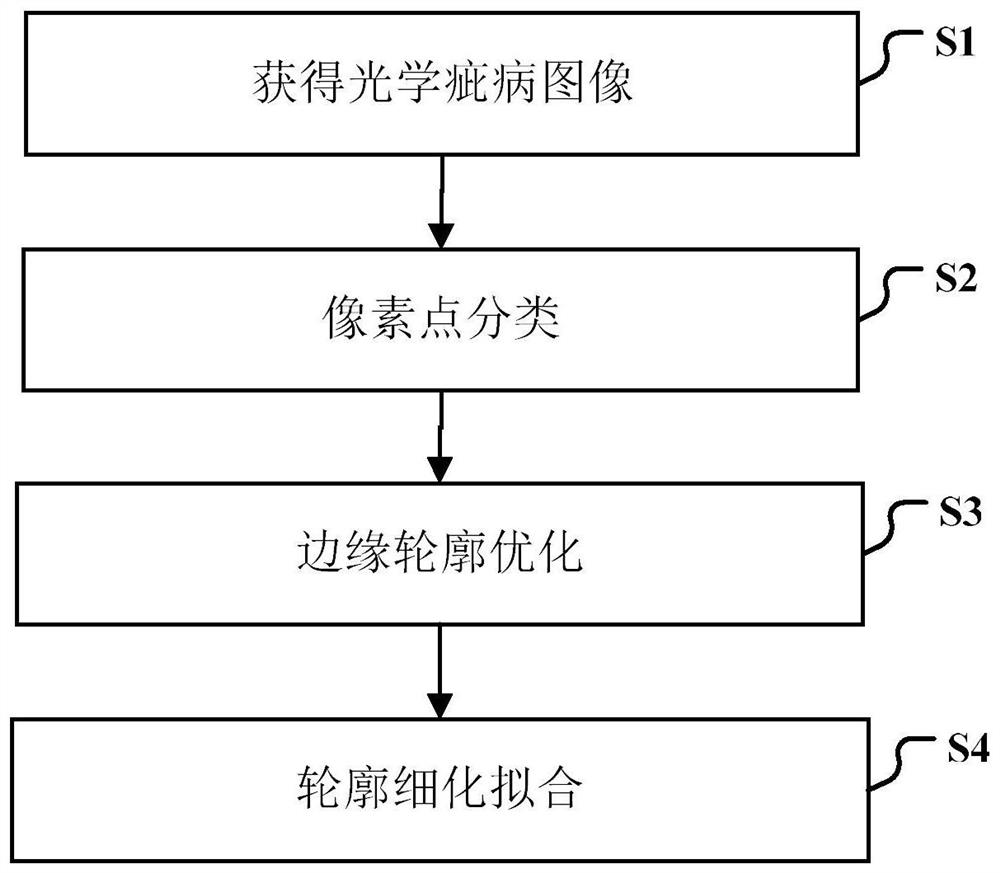

A contour detection and telescope technology, which is applied in the direction of measuring devices, optical testing flaws/defects, instruments, etc., can solve the problems of limited size of detection optical components, high cost, and complicated equipment assembly, so as to improve the fitting accuracy and enhance the intensity information The effect of features

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example

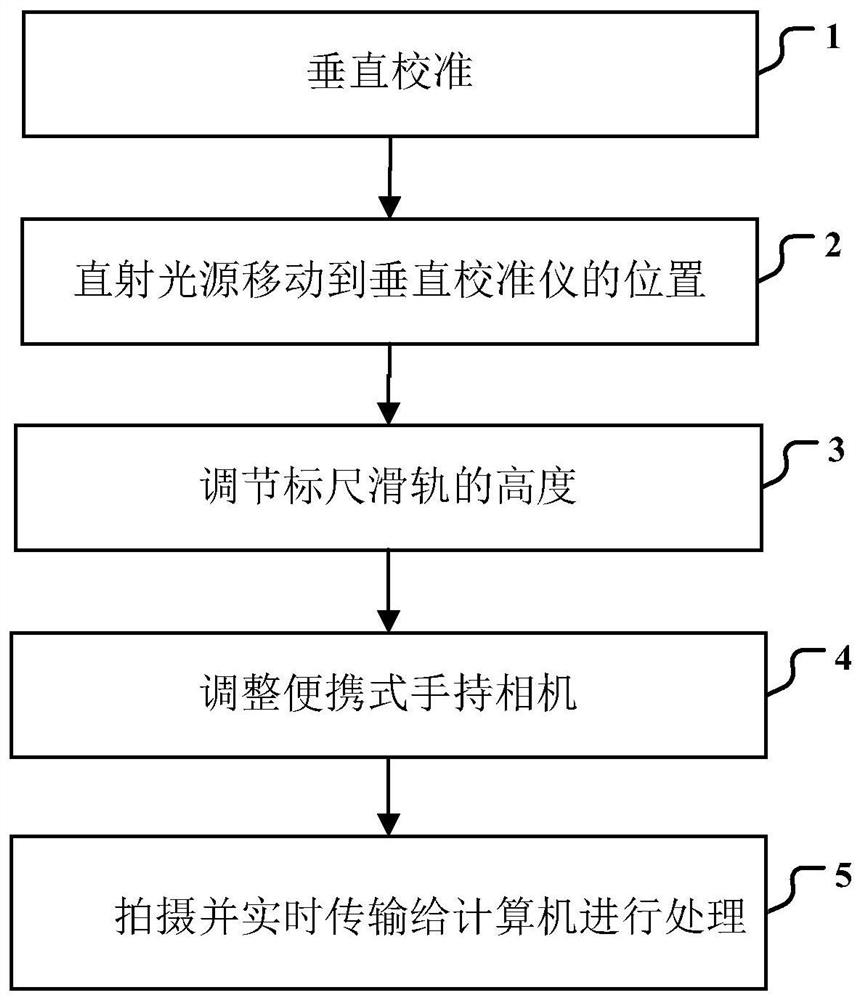

[0129] In this example, there are scratches on the mirror surface of the satellite telescope, Figure 6 There is a scratch at the upper left edge of the center, and particles formed by gas solidification adhere to the lens, and they are randomly and scatteredly distributed. use figure 1The surface flaw detection system of the satellite telescope lens shown in the figure collects the image of the surface flaw of the satellite telescope lens, turns on the vertical collimator, and makes the laser point irradiate the geometric center of the lens under test placed horizontally, so as to ensure that the vertical collimator is consistent with the lens of the satellite telescope under test. vertical. Adjust the position of the sliding assembly on the scale rail, move the direct light source to the position of the vertical calibrator, so that the center of the direct light source and the center of the lens to be tested are on the same axis. Adjust the height of the ruler slide rail s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com