System and method for calibrating 3D printer

A 3D printer, printer technology, applied in 3D object support structures, coating devices, manufacturing tools, etc., can solve problems such as poor layer-to-layer adhesion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] Reference will now be made in detail to exemplary implementations of the present teachings, examples of which are illustrated in the accompanying drawings. Wherever possible, the same reference numbers will be used throughout the drawings to refer to the same, like or like parts.

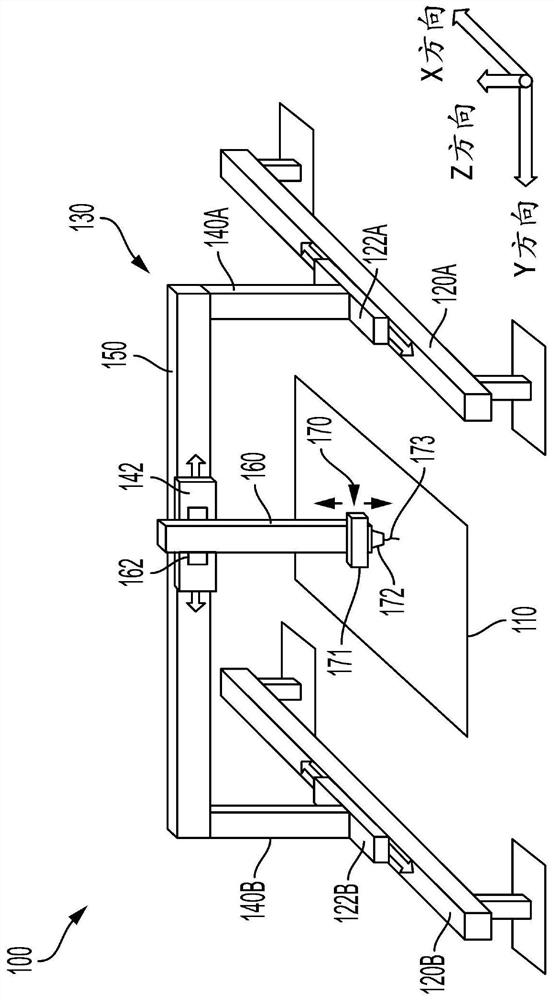

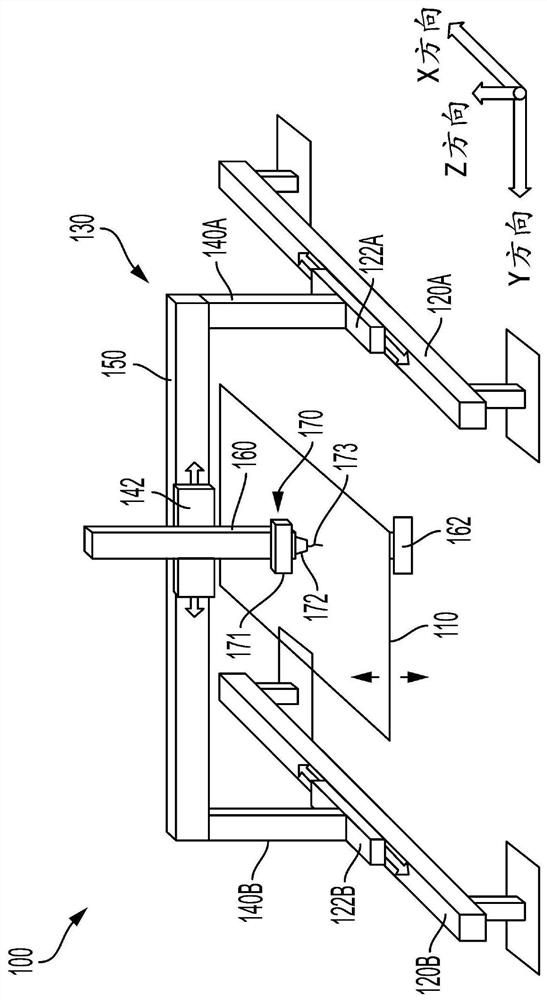

[0014] figure 1 A perspective view of a 3D printer 100 according to one embodiment is shown. As described below, printer 100 may be configured to move in three dimensions to print 3D objects on substrate 110 . Printer 100 may include one or more tracks (two shown: 120A, 120B). The rails 120A, 120B may be substantially parallel and extend along the X-axis.

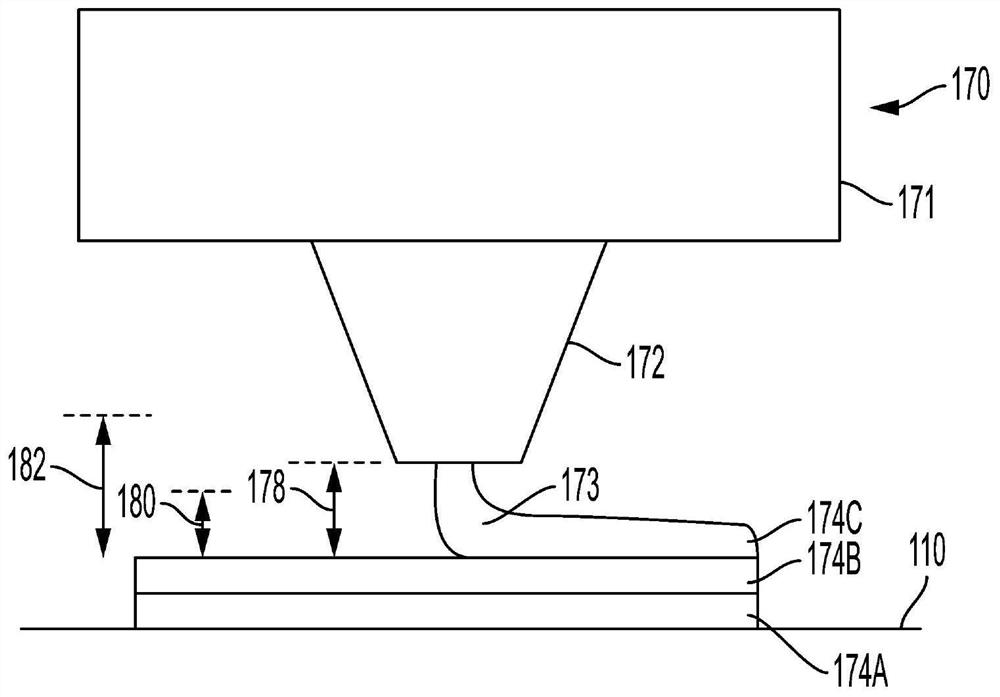

[0015] The printer 100 may also include a frame 130 . The frame 130 may be coupled to the rails 120A, 120B and configured to move relative to the rails 120A, 120B. Frame 130 may include one or more legs (two legs shown: 140A, 140B). The legs 140A, 140B may be coupled to the rails 120A, 120B and configured to move relative to the rail...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com