Fabricated partition wall formwork

A prefabricated and formwork technology, which is applied in the direction of walls, buildings, building components, etc., can solve the problems of poor sealing performance of partition wall formwork, and achieve the effect of improving sealing and tight connection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] The following is attached Figure 1-8 The application is described in further detail.

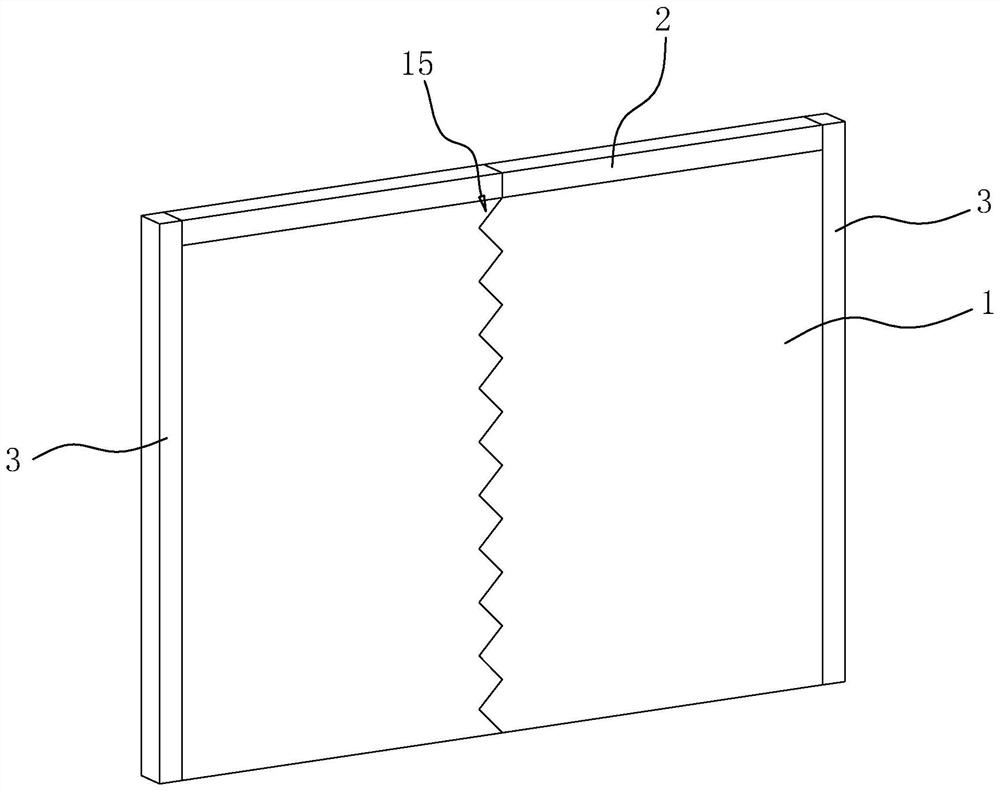

[0040] The embodiment of the present application discloses a prefabricated partition wall template. refer to figure 1 , a prefabricated partition wall template includes a number of splicing templates 1 that are spliced with each other along the horizontal direction, side edge banding panels 3 are respectively arranged on the left and right sides of the splicing template 1, and side edge panels 3 are respectively arranged on the upper side of each splicing template 1. Upper edge panel 2.

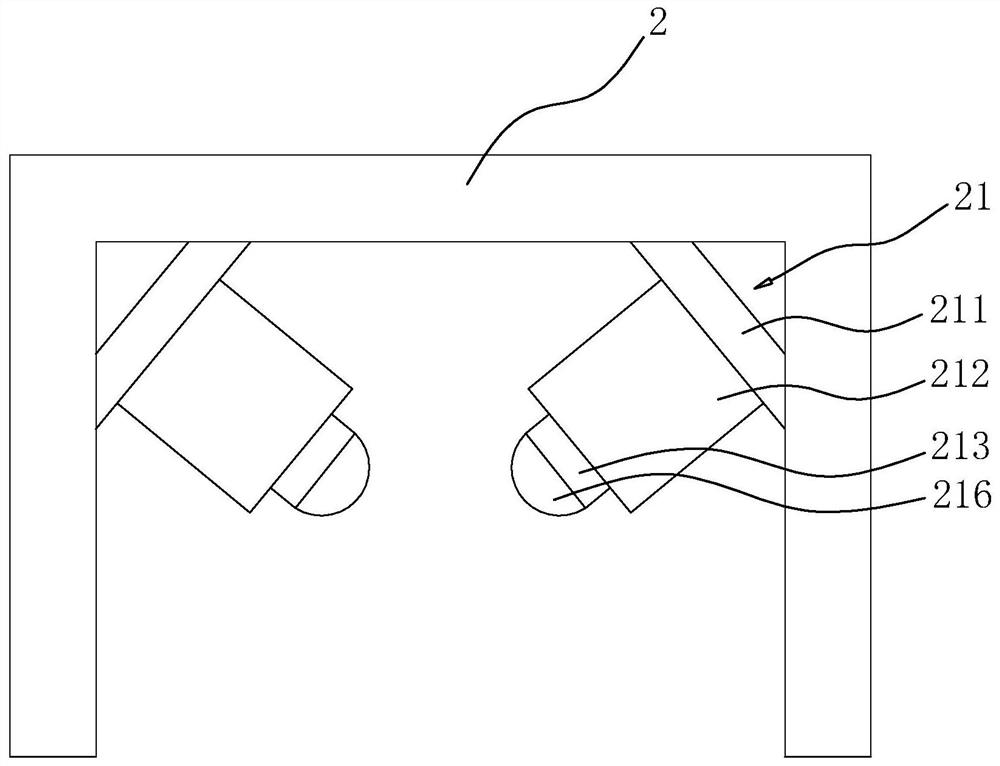

[0041] refer to figure 2 , the side edge banding plate 3 and the upper edge banding plate 2 are rectangular hollow structures, and the side walls of the side edge banding plate 3, the upper edge banding plate 2 and the splicing formwork 1 are all open.

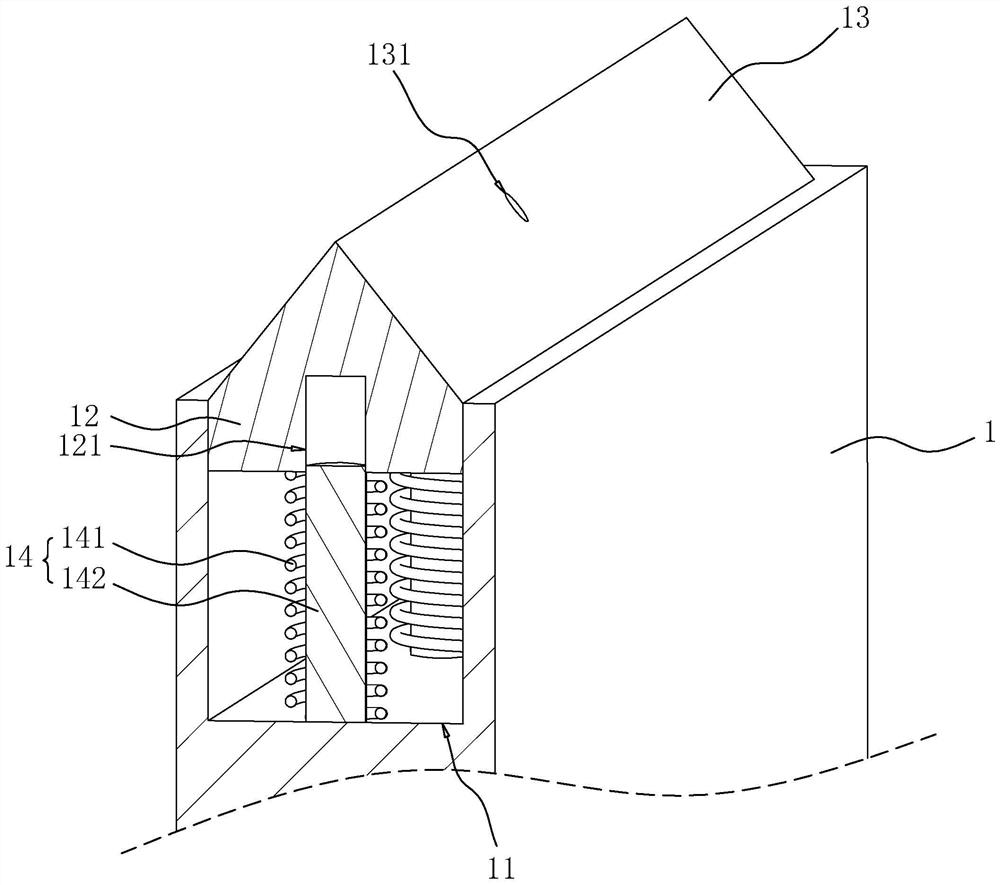

[0042] refer to image 3, on the side walls of the splicing formwork 1 connected with the side edge plate and the upper edge plate 2, there...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap