Smooth cable paying-off device

A pay-off device and cable technology, which is used in transportation and packaging, delivery of filamentous materials, thin material processing, etc., can solve problems such as cable rotation, cable shaft position cannot be adjusted at will, and large labor force to ensure stability The effect of rotation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

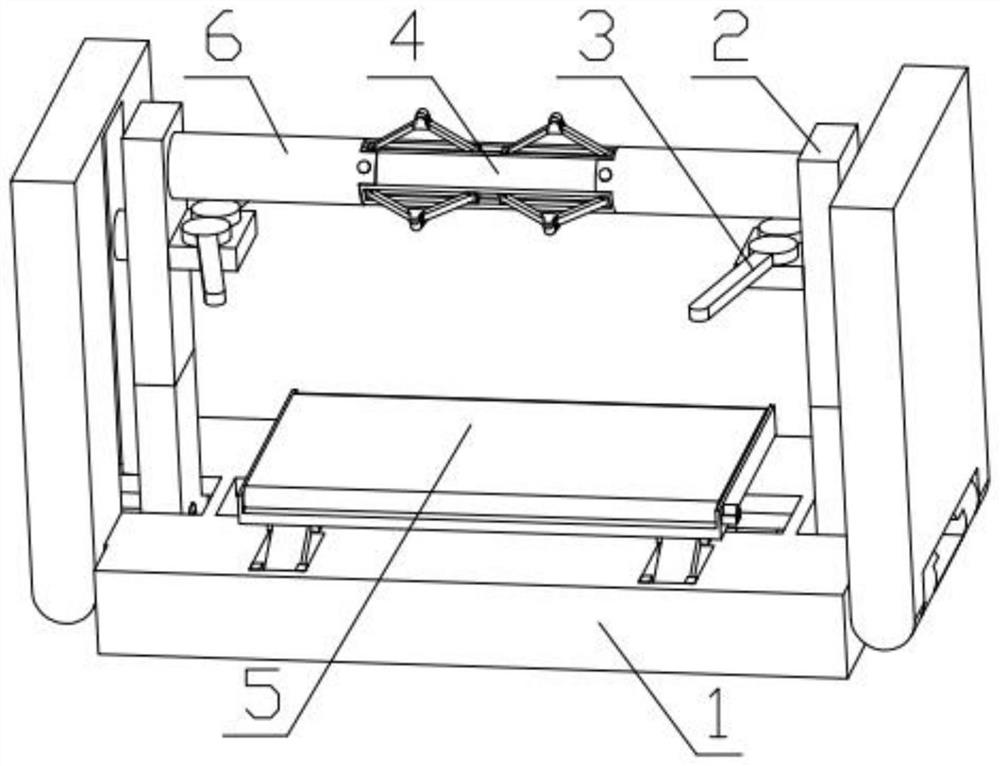

[0036] Combine below Figure 1-15 Describe this embodiment, a cable smooth pay-off device, including a folding base 1, a lifting mechanism 2, a position adjustment mechanism 3, a cable shaft positioning mechanism 4, a wire-releasing anti-jamming mechanism 5 and a connecting mechanism 6, the folding base 1 An anti-jamming mechanism 5 is fixedly installed on the top, and a lifting mechanism 2 is slidably installed in the groove of the folding base 1. A position adjustment mechanism 3 is fixedly installed on the lifting mechanism 2. In the groove, the cable shaft positioning mechanism 4 is slidably installed on the lifting mechanism 2 .

specific Embodiment approach 2

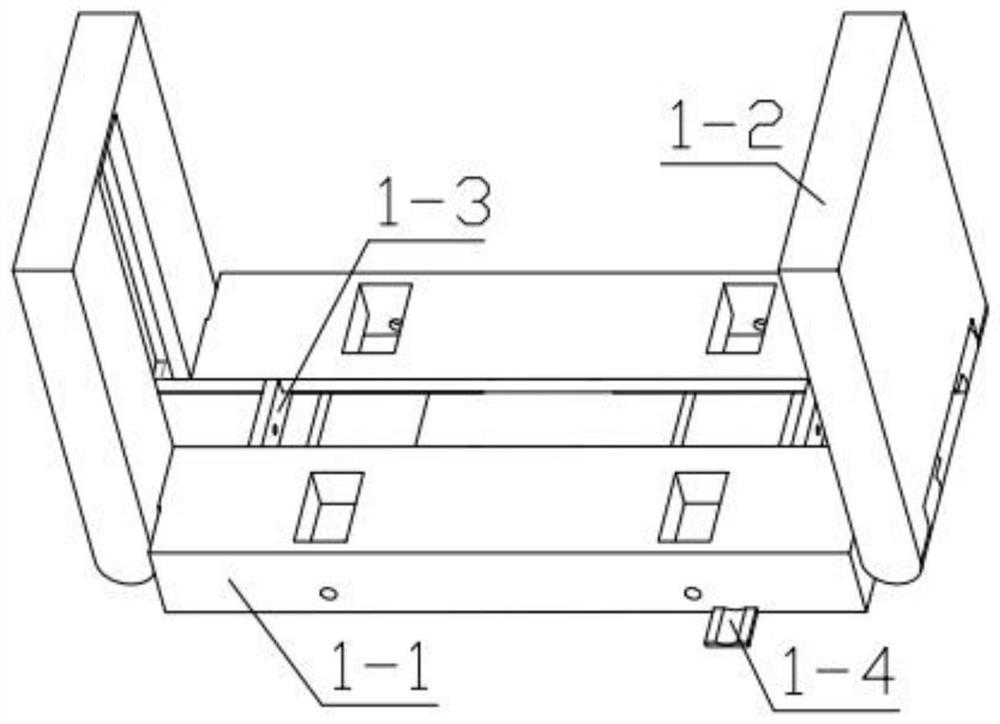

[0038] Combine below Figure 1-15 This embodiment will be described. This embodiment will further explain Embodiment 1. The folding base 1 includes a main base plate 1-1, a side slideway plate 1-2, a positioning plate 1-3, and a motor fixing plate 1-4. The two ends of the base plate 1-1 are respectively hinged with side slideway plates 1-2, the two sides of the main base plate 1-1 are fixedly installed with a positioning plate 1-3, and the main base plate 1-1 is fixedly installed with a motor fixing plate 1-4 .

specific Embodiment approach 3

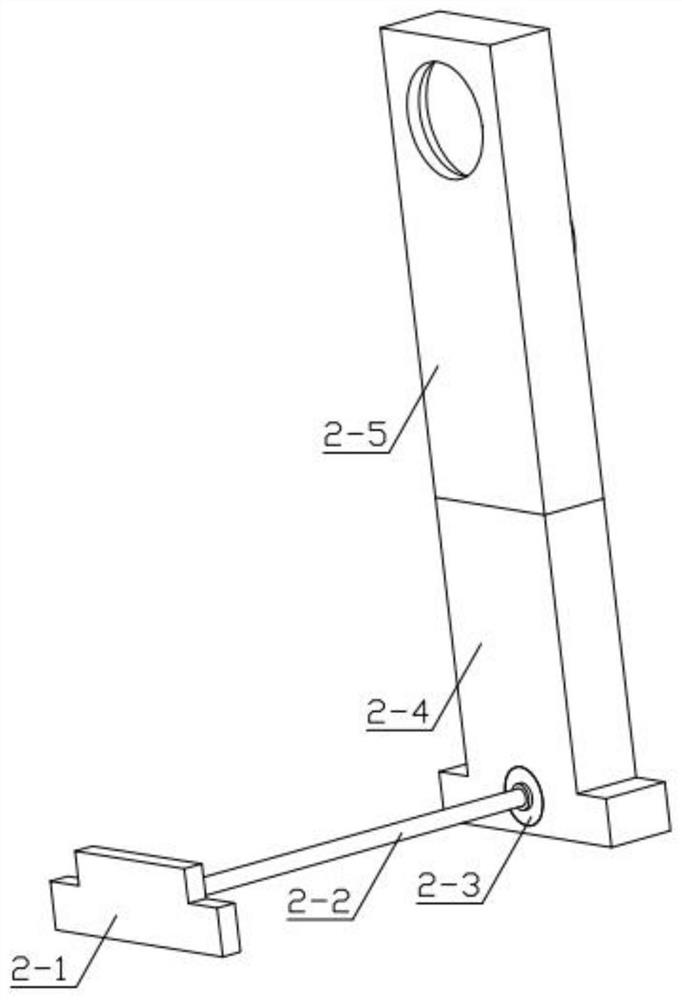

[0040] Combine below Figure 1-15 Describe this embodiment, this embodiment will further explain the second embodiment, the lifting mechanism 2 includes a limit slider 2-1, a displacement threaded rod 2-2, a displacement motor 2-3, a sliding base 2-4, Upper connecting piece 2-5, shaft rotating motor 2-6, gear for rotation 2-7, limit rod 2-8, hydraulic rod 2-9, limit slider 2-1 is slidably installed on the main base plate 1-1 In the groove provided above, one end of the displacement threaded rod 2-2 is rotated and installed in the groove provided on the limit slider 2-1, and the other end of the displacement threaded rod 2-2 is fixedly mounted on the displacement motor 2-3. At the output end, the displacement motor 2-3 is fixedly installed in the groove provided on the sliding base 2-4, and the sliding base 2-4 is slidably installed in the groove provided on the main base plate 1-1, and the concave groove of the sliding base 2-4 The hydraulic rod 2-9 is fixedly installed in th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com