Patents

Literature

39results about How to "Convenient winding operation" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Isolation type non-woven fabric textile winding machine and application method

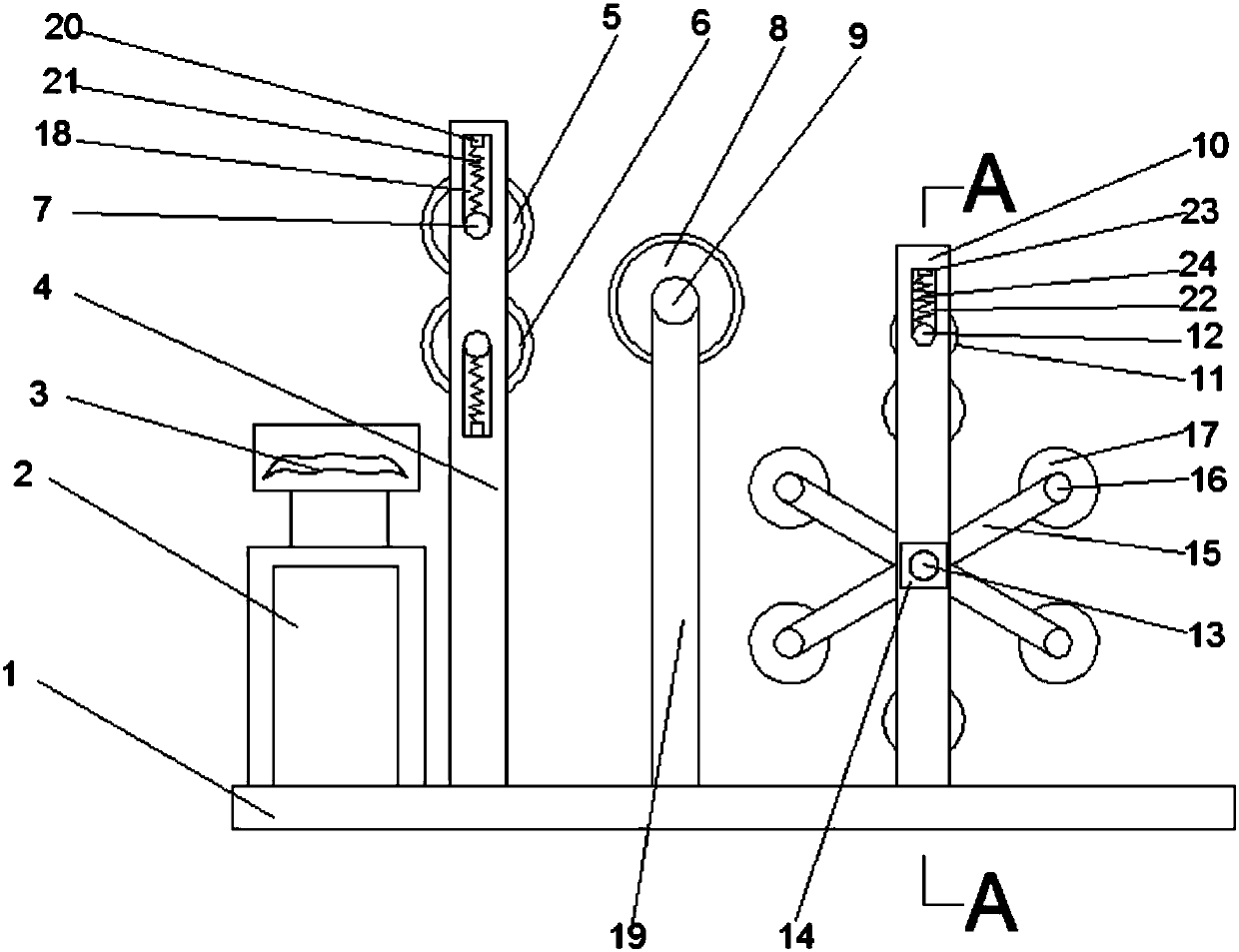

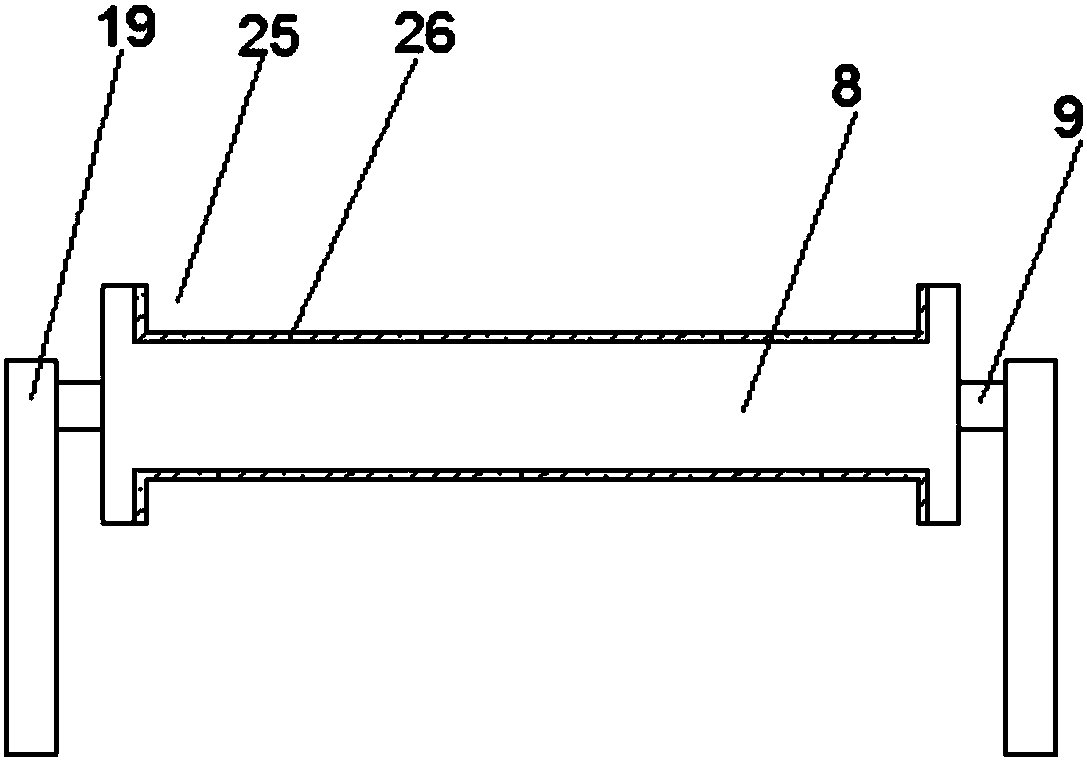

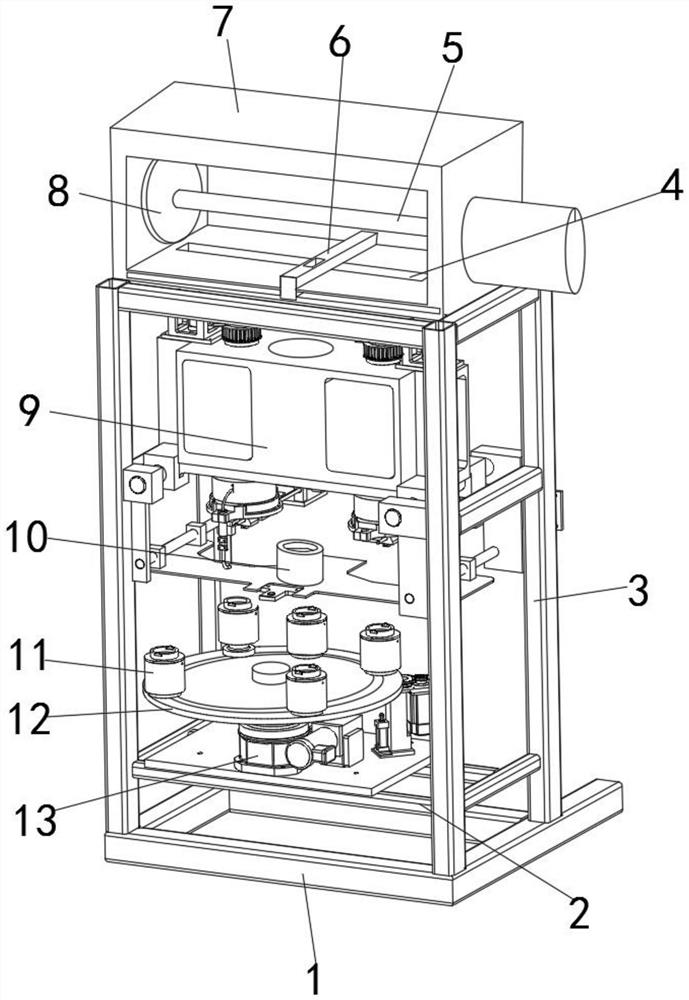

The invention discloses an isolation type non-woven fabric textile winding machine which belongs to the technical field of textile winding. A cooling fan is arranged at the top of a fixed bracket; anupper flattening roller and a lower flattening roller are arranged at the top of a first bracket in sequence from top to bottom; a tensioning roller is arranged at the top of a third bracket; the tensioning roller is connected onto the third bracket through a second connecting shaft; a second through hole is formed in the top of a side wall of a second bracket; a second fixed block is arranged atthe top of the second through hole; a second rigid spring is arranged at the bottom of the second fixed block; a third connecting shaft is provided with a tracking roller; six groups of winding rollers with the same structure are arranged below the tracking roller; the winding rollers are connected with a connecting frame through a fourth connecting shaft; a ratchet wheel mechanism which is matched with a mounting groove is arranged at the left end of a fifth connecting shaft. The winding machine disclosed by the invention is reasonable in structural design and high in automation degree; simple and convenient textile winding work can be ensured and the winding effect of the fabric is remarkable.

Owner:宁夏中恒创越新材料科技有限公司

Convenient-to-disassemble/assemble/repair cable winding device

InactiveCN108639872AEasy to disassemble and replaceRealize winding operationEngineeringConductor Coil

The invention discloses a convenient-to-disassemble / assemble / repair cable winding device. The cable winding device comprises a base, a winding drum, a guide movable pulley, an elastic support component, a locking sleeve and a guide fixed pulley, wherein a fixed sleeve is fixedly mounted on a bracket located at the front end of the base, a guide slider is arranged in the fixed sleeve in a sliding manner, a clamping spring is arranged in the fixed sleeve, a support presser rod is also arranged on the fixed sleeve in a sliding manner and penetrates through the fixed sleeve, one end of the supportpresser rod is in rotating connection with the guide slider, a connecting sleeve is fixedly mounted at the other end of the support presser rod, and the connecting sleeve and the support rod are in detachable connection through a connecting bolt. The structure is simple and reasonable, the winding effect is great, the quality is high, and the use is flexible and convenient due to the adjustable pretension force of the elastic support component. The two ends of the winding drum are both fixedly mounted by adopting a detachable connecting mode, so that the disassembly, assembly and change of the winding drum are facilitated, and the cable winding operation is facilitated. The cable winding device is suitable for popularization and use.

Owner:贵港市鼎金电子产品有限公司

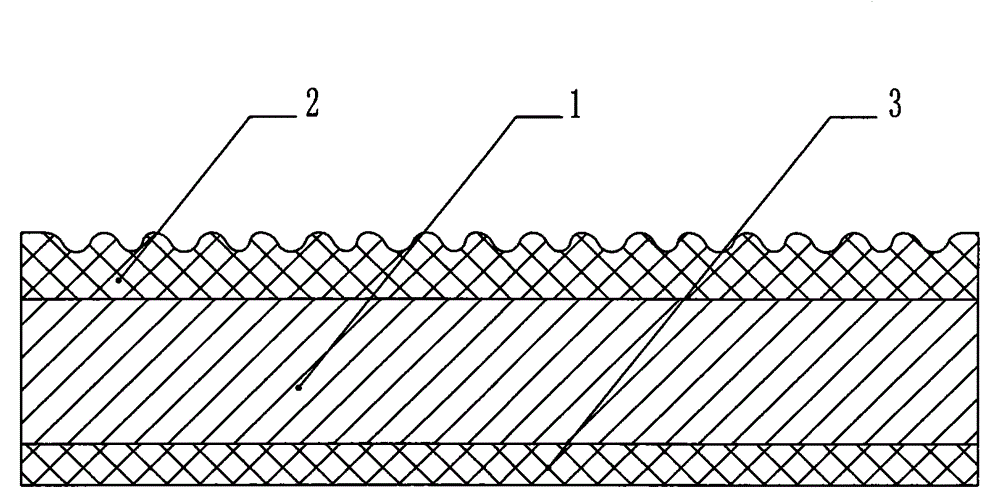

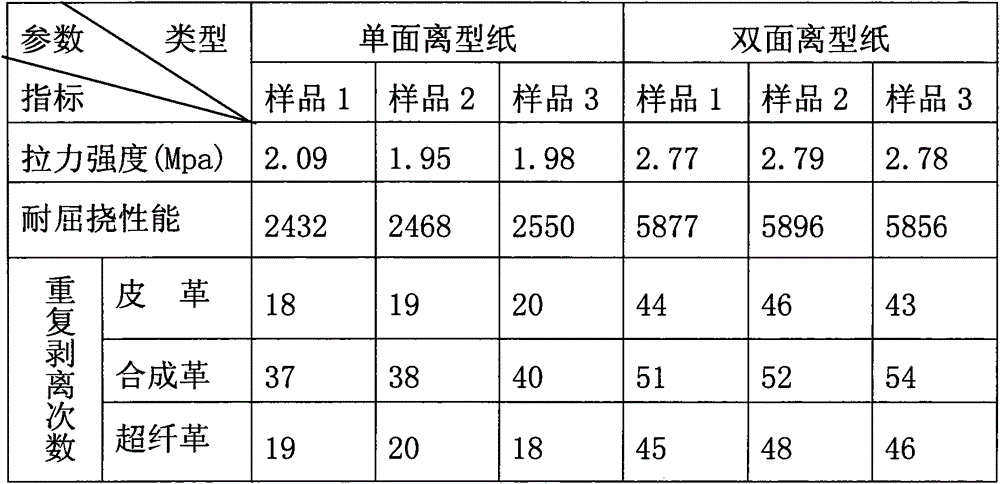

Two-sided release paper and production method thereof

InactiveCN104097377AHigh tensile strengthImprove flex resistanceSynthetic resin layered productsLaminationPaper basedPulp and paper industry

The invention relates to a piece of two-sided release paper. The two-sided release paper comprises a raw paper base layer; a pattern resin layer is arranged on the surface of the raw paper base layer; the pattern resin layer is arranged on the right side of the raw paper base layer; a balance resin layer is arranged on the back side of the raw paper base layer. The two-sided release paper has the benefits that filming and coating the pattern resin layer and the balance resin layer on the right side and the back side of the raw paper base layer respectively can be utilized to greatly improve the tensile strength and the flexural property of the release paper, so that the release frequency of the release paper can be greatly increased, the recycling rate of the release paper can be greatly improved, the production cost of copying patterns on leather products can be reduced, and dependence on foreign products can be avoided; besides, during the process of copying the patterns and drying and releasing leather surface materials, the release paper curls due to the reduction of the edge parts of the release paper, so that the release paper is convenient for releasing, rolling operation and recycling utilization; moreover, the paper ration of raw paper can be lowered appropriately, and the production cost of the release paper can be reduced maximally.

Owner:ZHEJIANG HAOBO SHOES MATERIAL

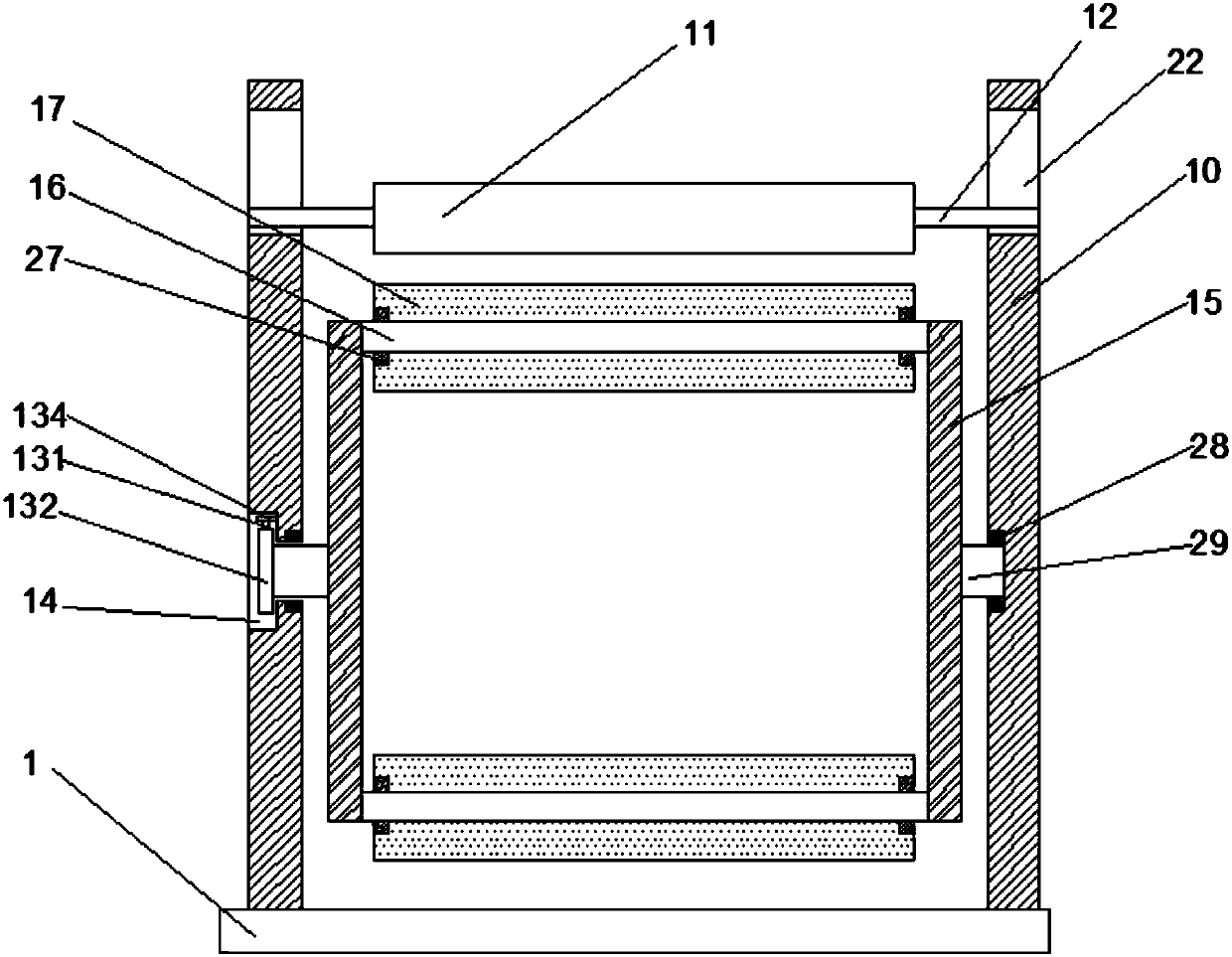

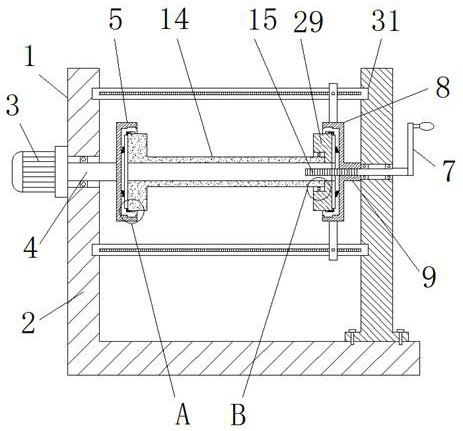

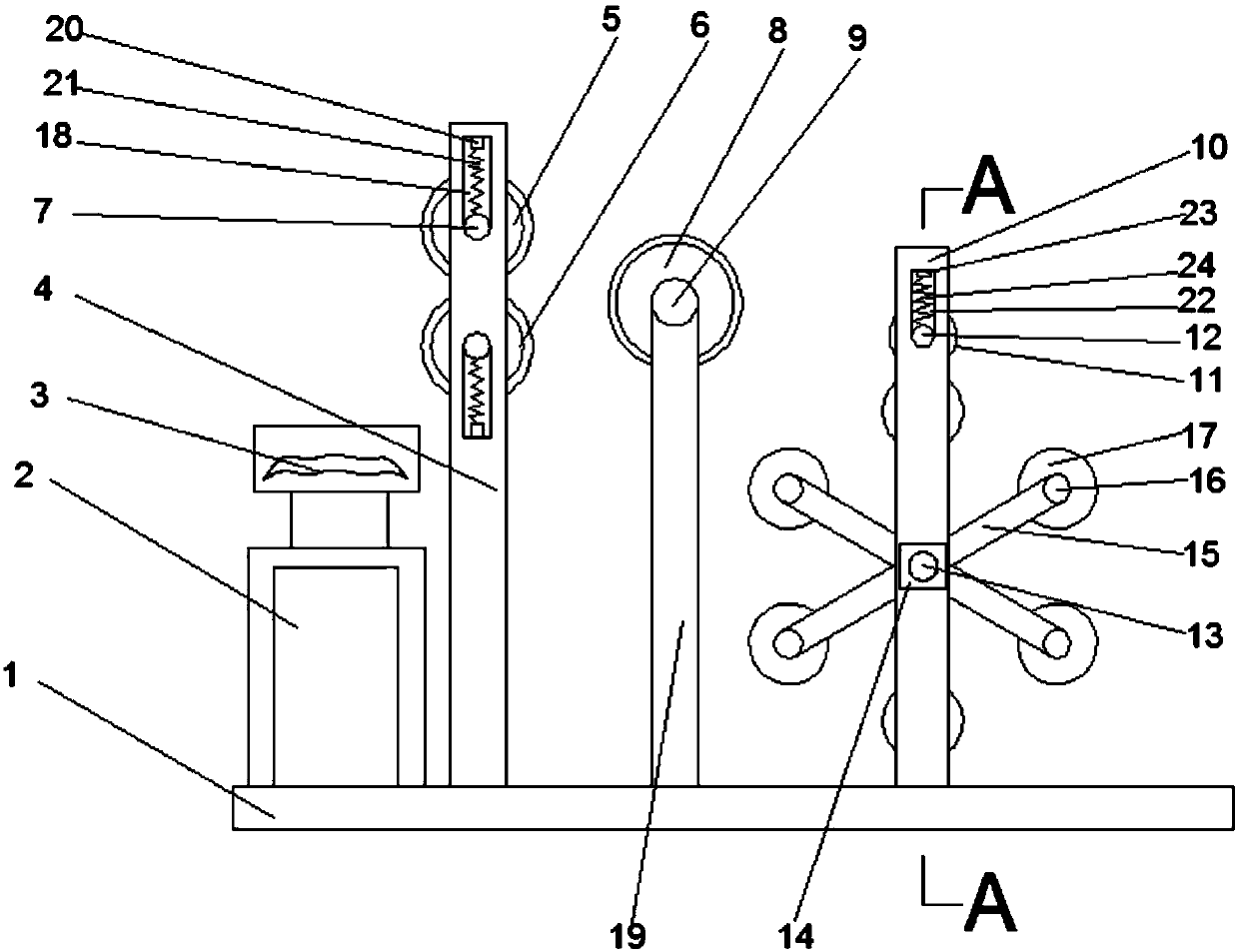

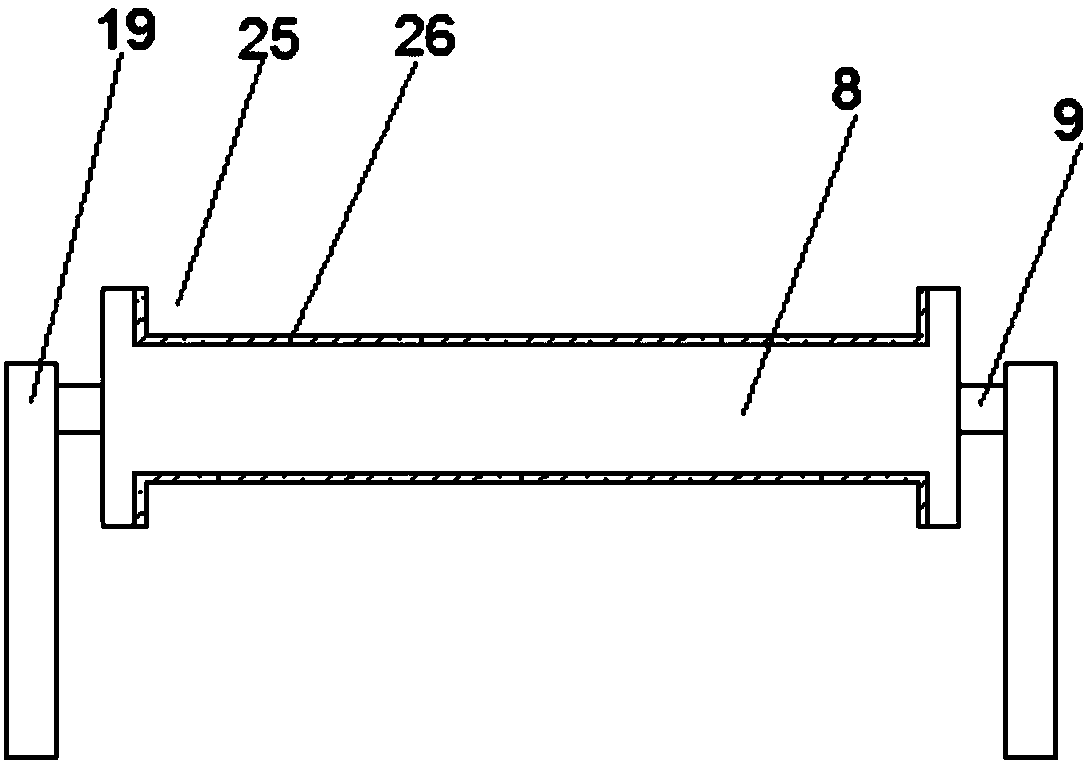

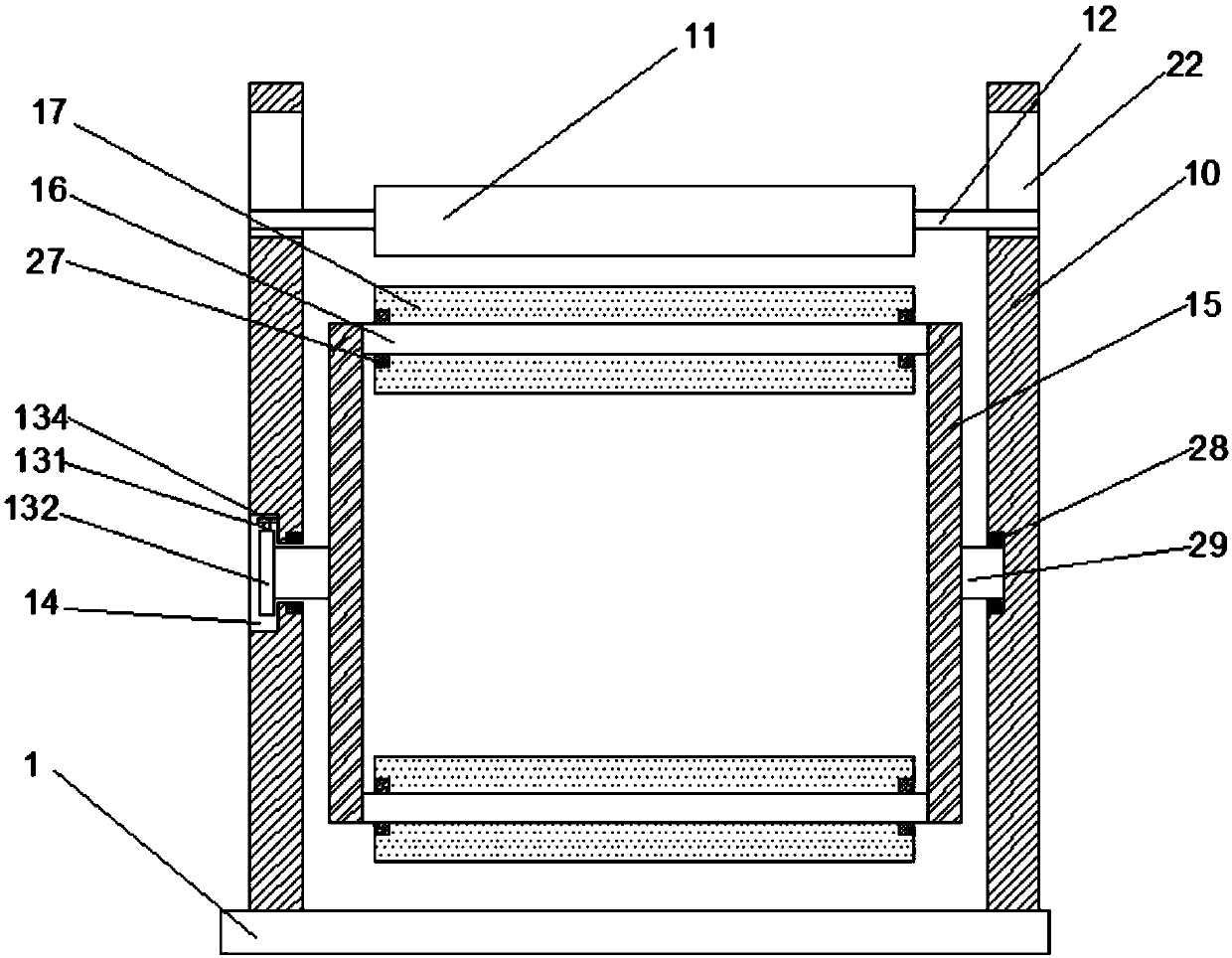

Water resistance detection device for polyethylene polypropylene fiber composite waterproof roll

InactiveCN106814021AConvenient samplingFast winding controlPermeability/surface area analysisFixed frameControl switch

The invention discloses a polyethylene polypropylene fiber composite waterproof membrane waterproof detection device, which comprises a frame, an unwinding roller is arranged on one side of the frame, a winding roller is arranged on the other side of the frame, and the top of the frame There is a cylinder on the top, and a piston rod is arranged on the lower part of the cylinder. The upper end of the piston rod is connected with the cylinder. The lower end of the piston rod is provided with a fixing frame. Installed on the lower part of the fixed frame through the installation shaft; the top of the frame is provided with an infusion machine, the lower part of the infusion machine is provided with an infusion pipeline, the upper part of the infusion pipeline and the infusion machine are provided with a control pump, and the lower part of the infusion pipeline is provided with an infusion The shell and the infusion pipeline are provided with a control switch, and the lower part of the infusion shell is provided with several liquid outlet pipes. The invention can conveniently carry out rapid winding control on the polyethylene polypropylene fiber composite waterproof coiled material, and conveniently carry out sampling detection on the waterproofness of the polyethylene polypropylene fiber composite waterproof coiled material.

Owner:SUZHOU ZHONGXINYUAN MICROELECTRONICS CO LTD

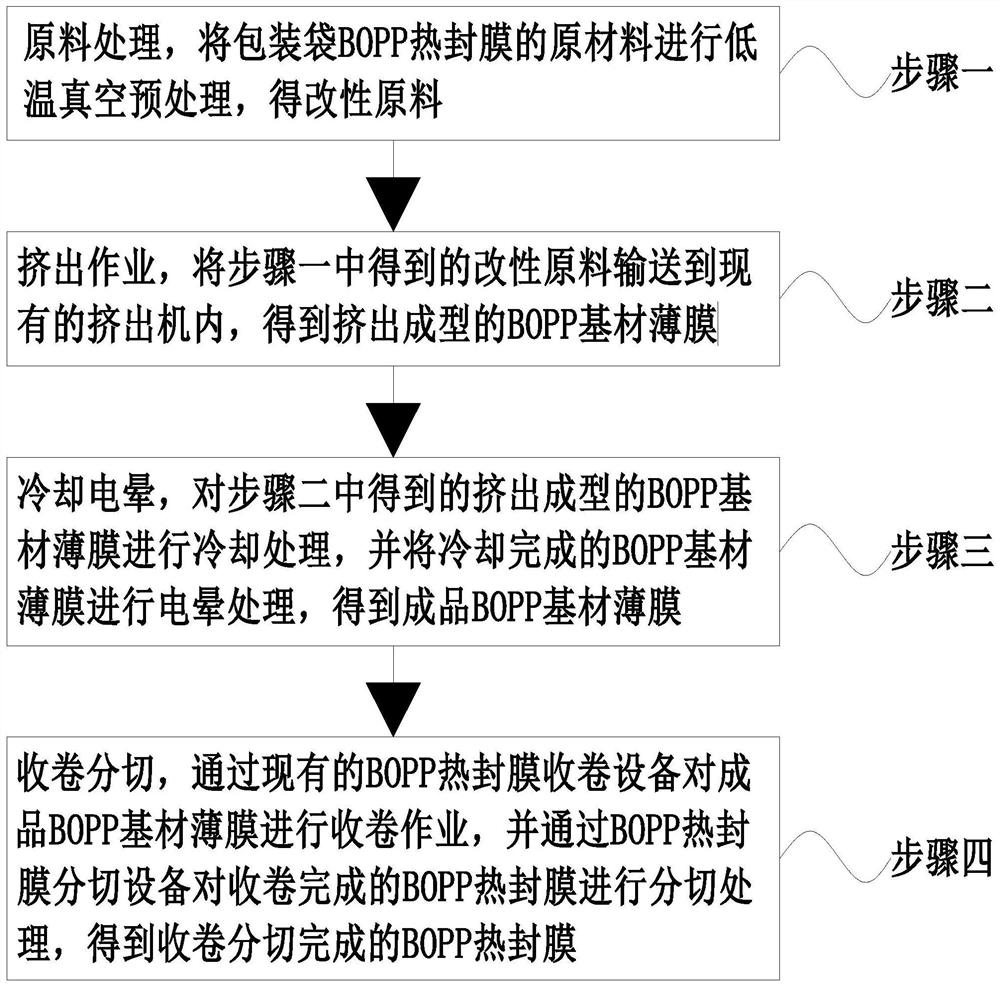

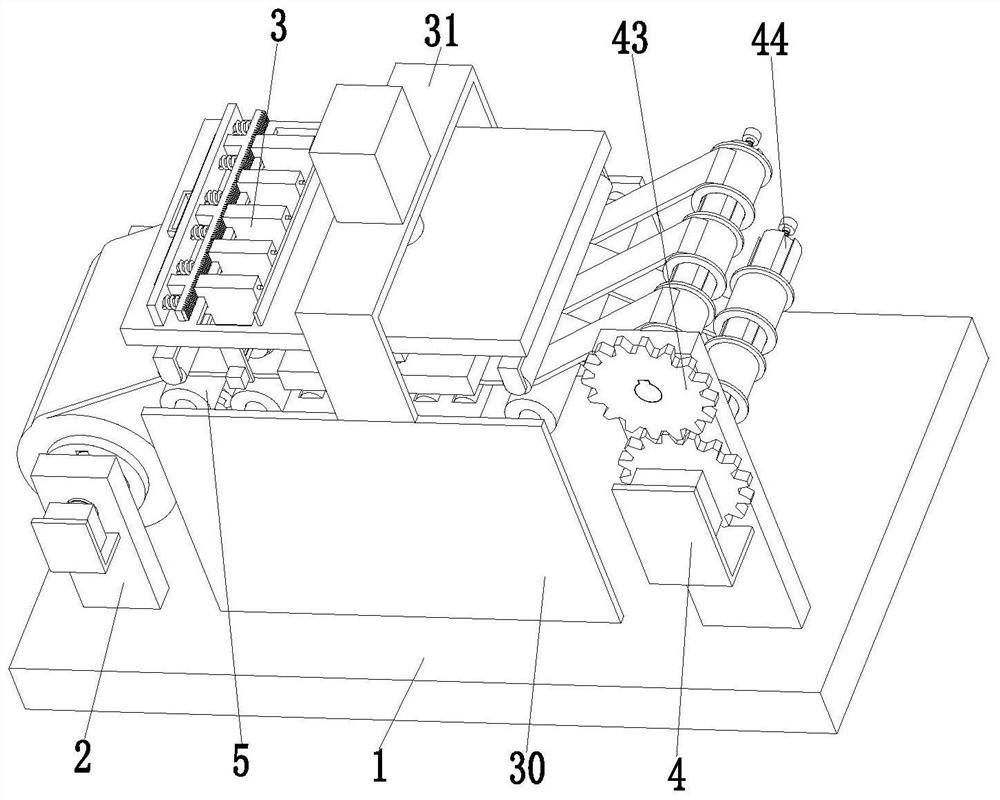

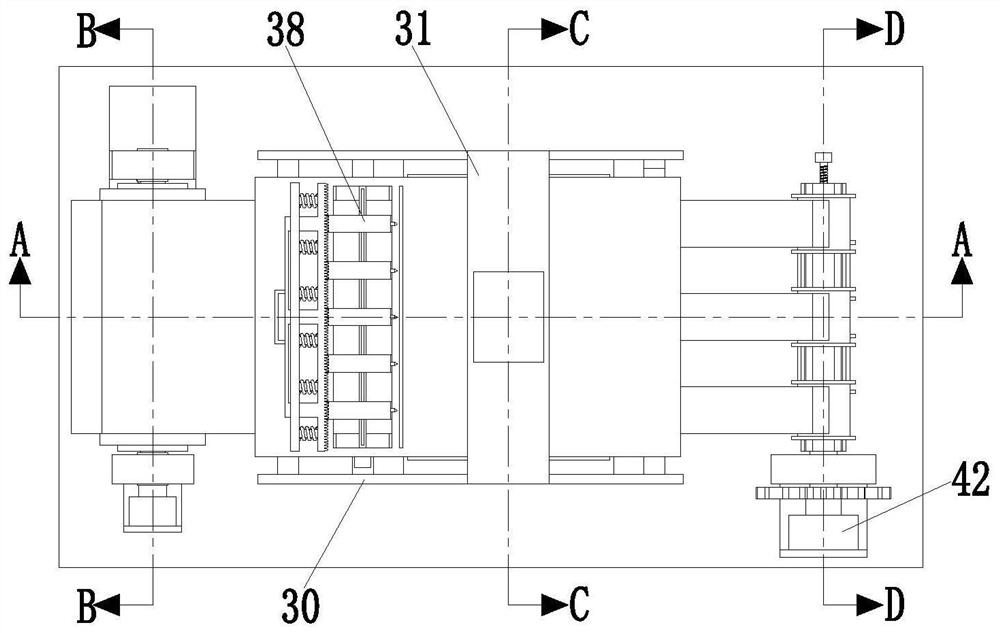

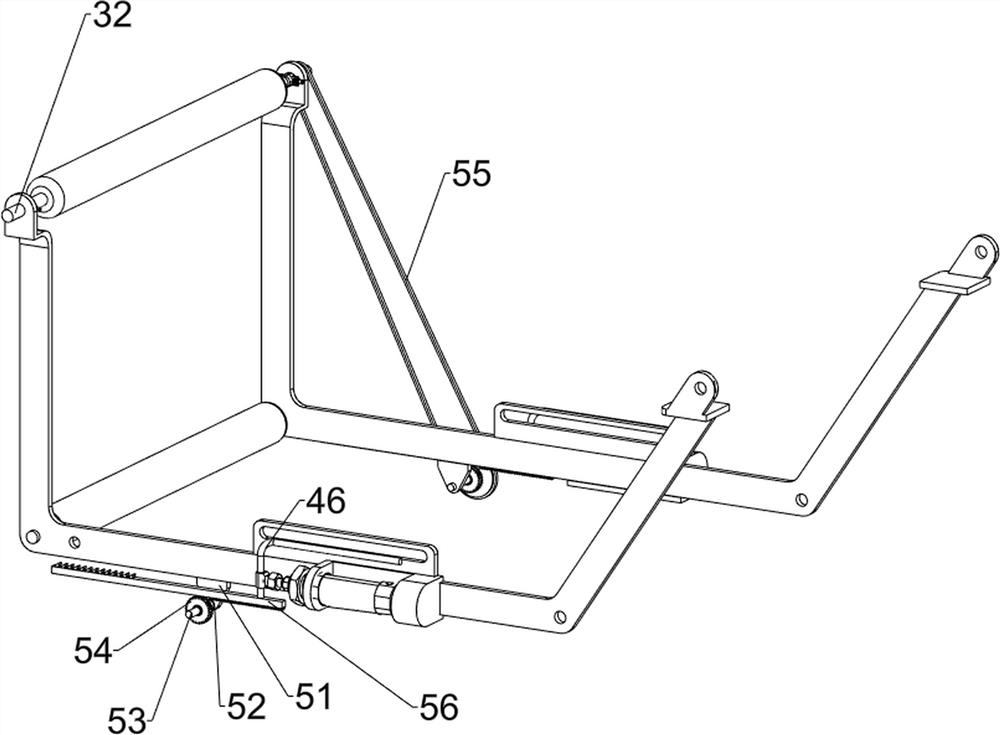

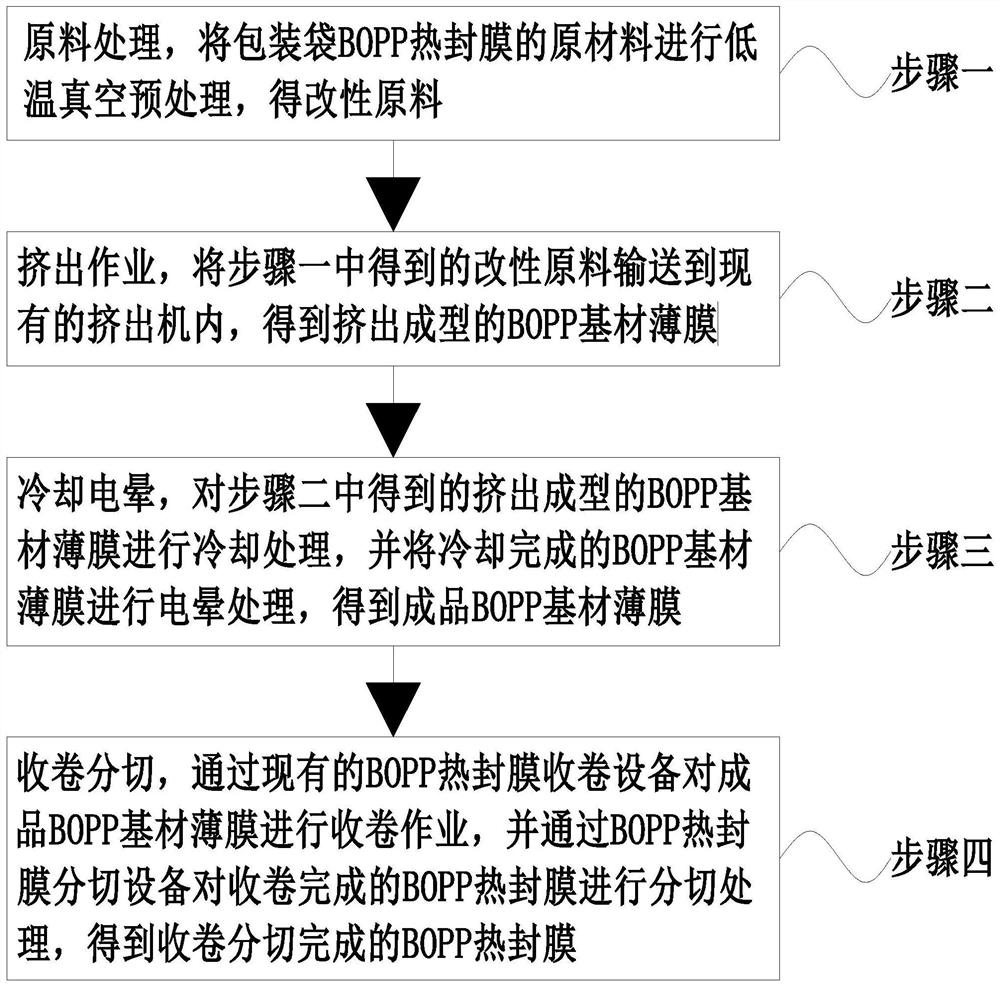

Preparation technology of BOPP heat-sealing film of packaging bag

ActiveCN113844943AImprove efficiencyQuality improvementArticle deliveryWebs handlingEngineeringMechanical engineering

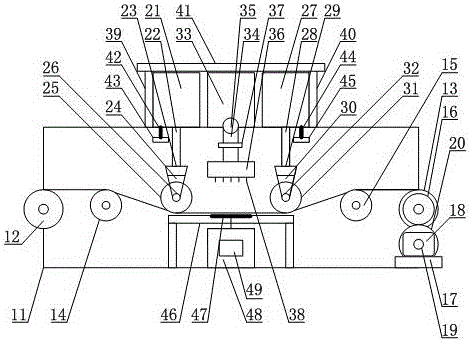

The invention relates to a preparation technology of a BOPP heat-sealing film of a packaging bag. The preparation technology mainly comprises the following steps of raw material treatment, extrusion operation, cooling corona, winding and slitting, and the like, wherein used BOPP heat-sealing film slitting equipment comprises an operation table, a roll feeding mechanism, a cutting mechanism and a winding mechanism; the roll feeding mechanism is installed at the left end of the operation table; the cutting mechanism is installed in the middle of the operation table; and the rolling mechanism is installed at the right end of the operation table. The preparation technology can solve the following problems existing during slitting of the BOPP heat-sealing film of the packaging bag: 1, when an existing BOPP heat-sealing film of the packaging bag is slit, the space between cutters needs to be adjusted, however, a traditional slitting mechanism is an integrated cutter, the cutters with different spaces need to be replaced, which is troublesome, and the slitting efficiency and quality of the BOPP heat-sealing film of the packaging bag are reduced; and 2, after the BOPP heat-sealing film of the packaging bag is slit, stable winding operation cannot be conducted on the BOPP heat-sealing film of the packaging bag, and the winding efficiency and quality of the BOPP heat-sealing film of the packaging bag are affected.

Owner:TIANJIN HUAHENG PACKAGING MATERIALS +1

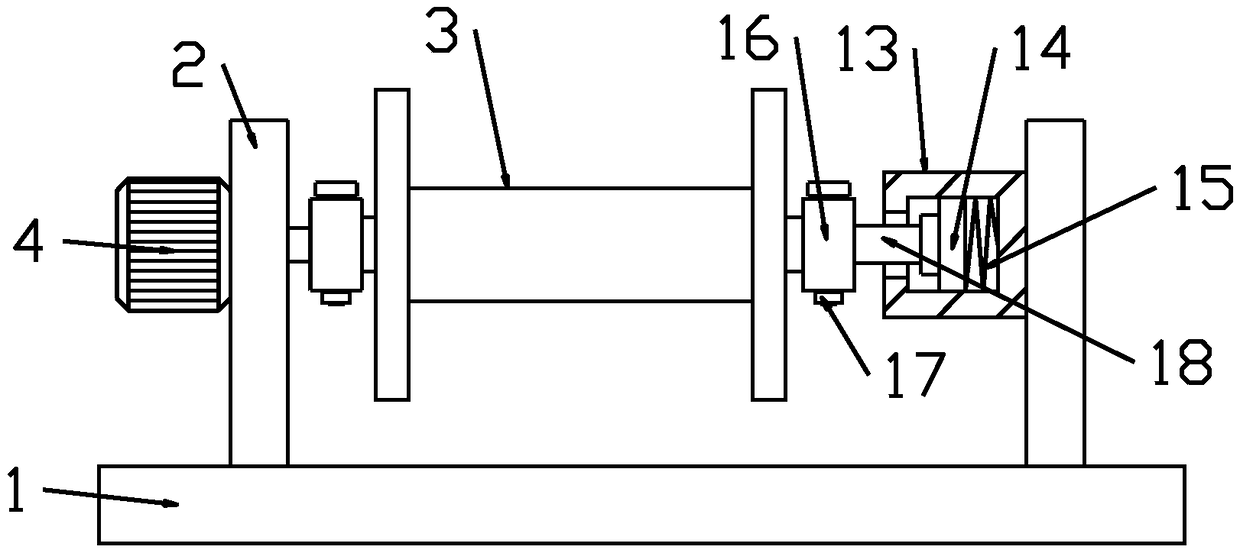

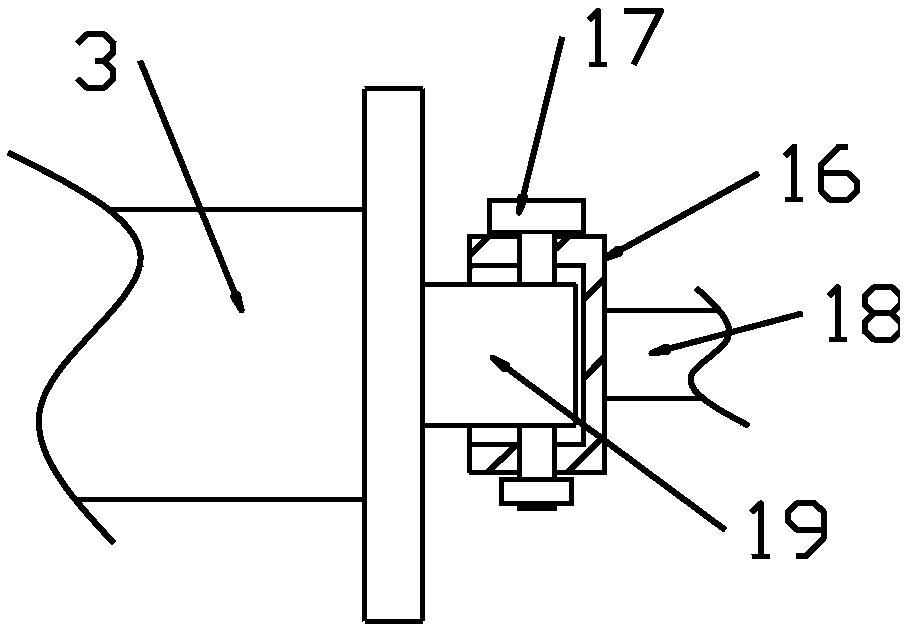

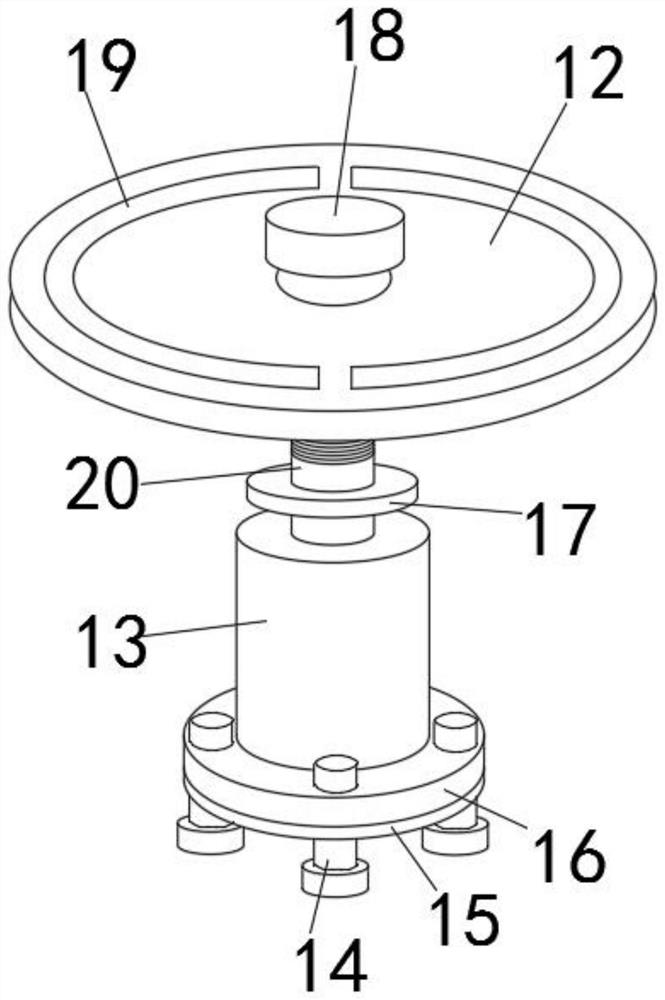

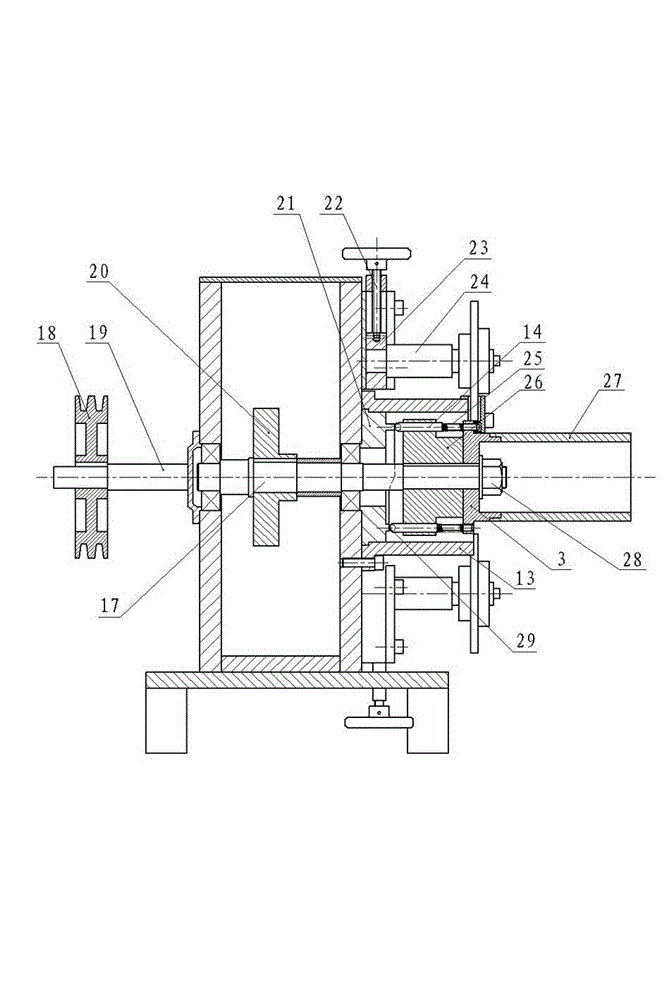

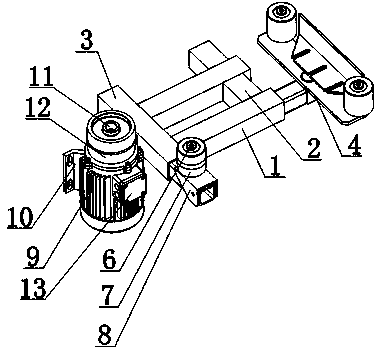

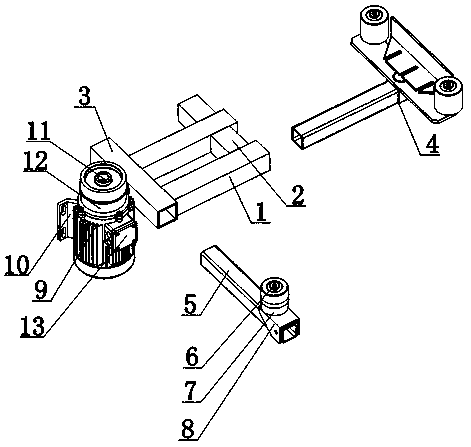

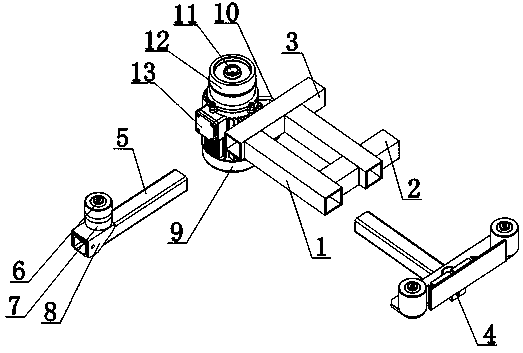

Transmission structure of winding main shaft on winding machine

The invention discloses a transmission structure of a winding main shaft on a winding machine, which comprises a motor and a synchronous belt connected with a motor output shaft. The synchronous belt is connected with a main shaft synchronous wheel arranged on the winding main shaft; and the winding main shaft is connected with an eccentric shaft through a key. The transmission structure is characterized in that the main shaft synchronous wheel is connected with the winding main shaft through a bearing assembly; the top end of the eccentric shaft is fixedly installed in a machine head lifting mechanism; a winding component is connected with the main shaft synchronous wheel through a winding arm connecting seat; and a winding mould component is installed on the eccentric shaft. The transmission structure has the advantages that the motor in the transmission structure drives the main shaft synchronous wheel to rotate through the synchronous belt, and the winding main shaft and the eccentric shaft do not rotate, so that the abrasion and the noise caused by the high-speed rotation are reduced, and the service life is prolonged; and meanwhile, the winding mould is installed on the fixed eccentric shaft, so that the vibration generated by rotation is reduced, and the operation stability is improved.

Owner:NIDE MECHANICAL EQUIP

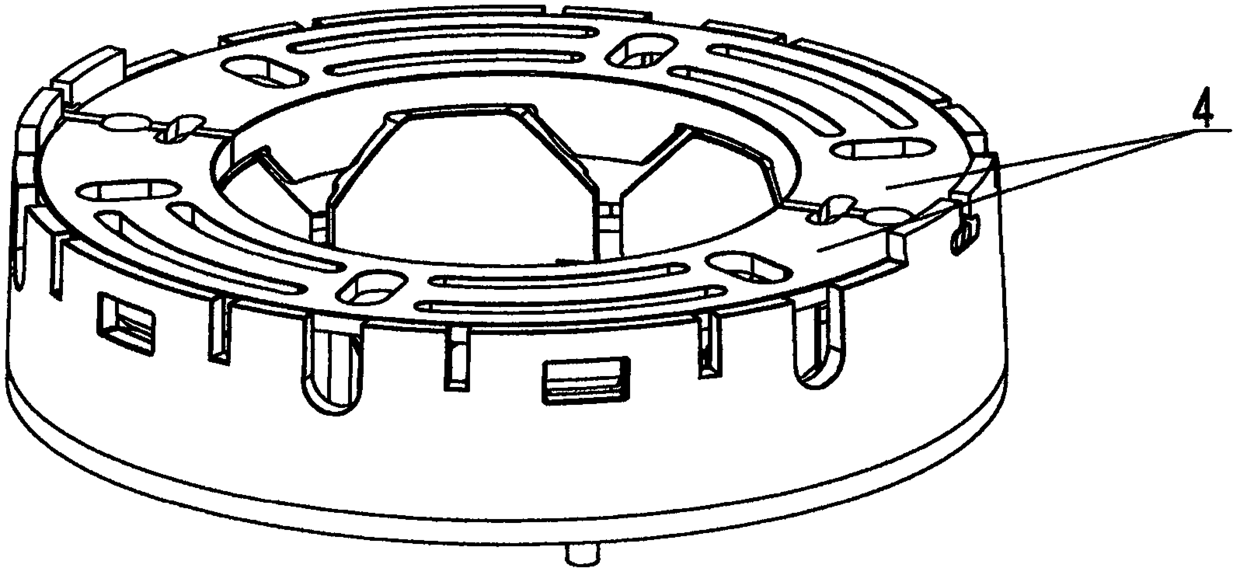

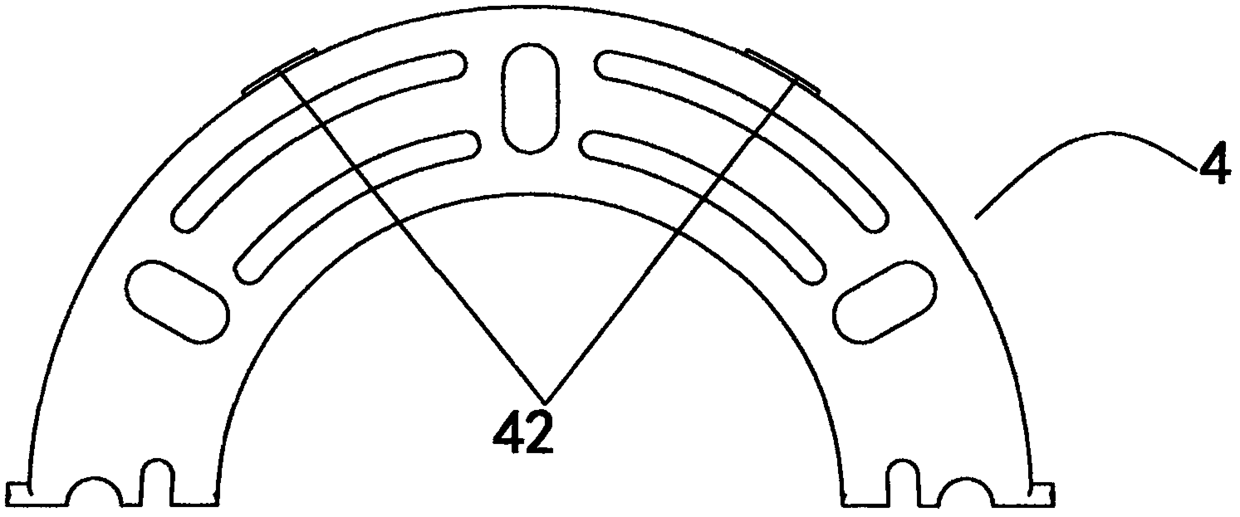

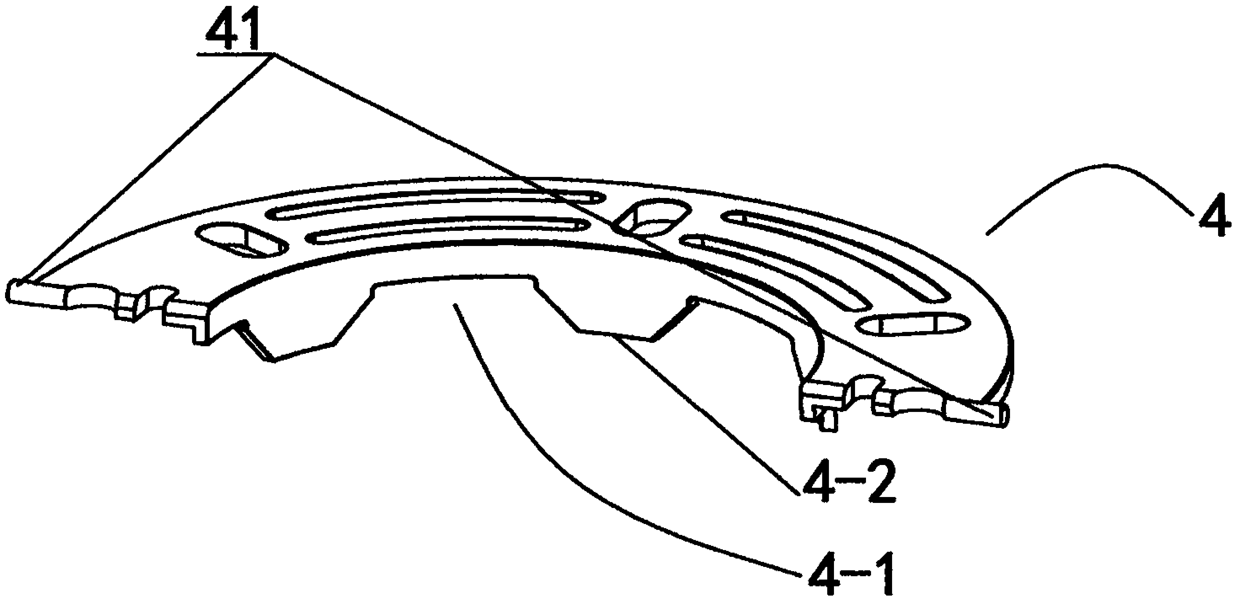

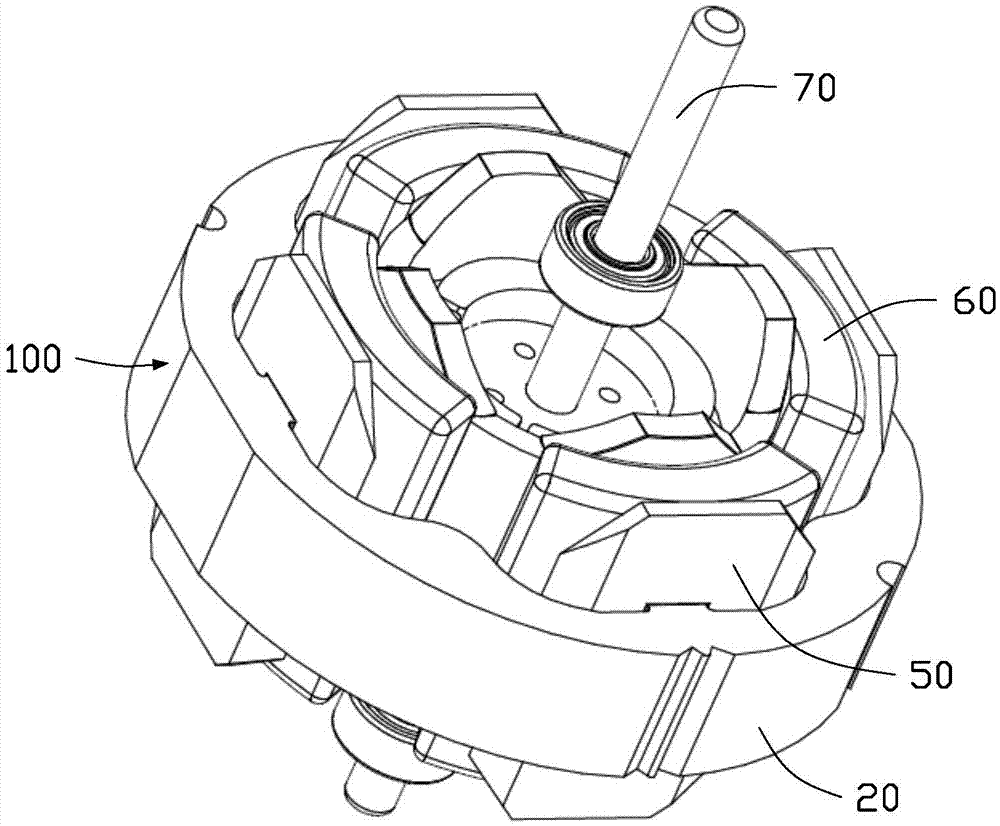

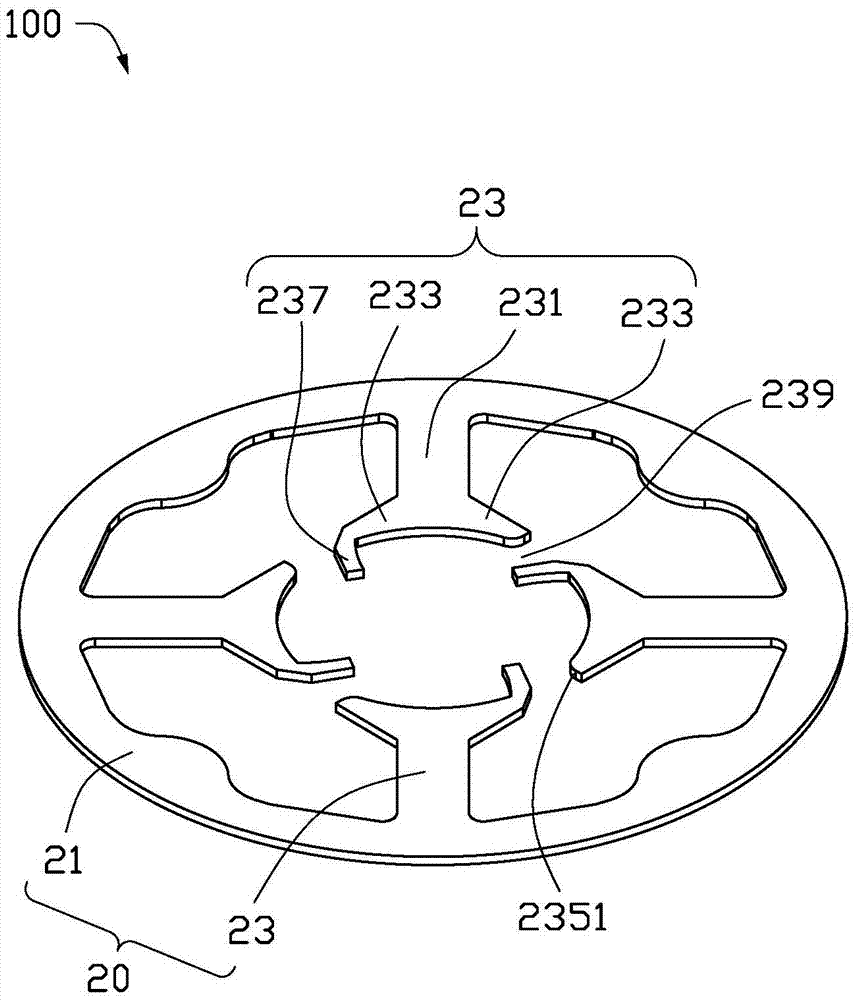

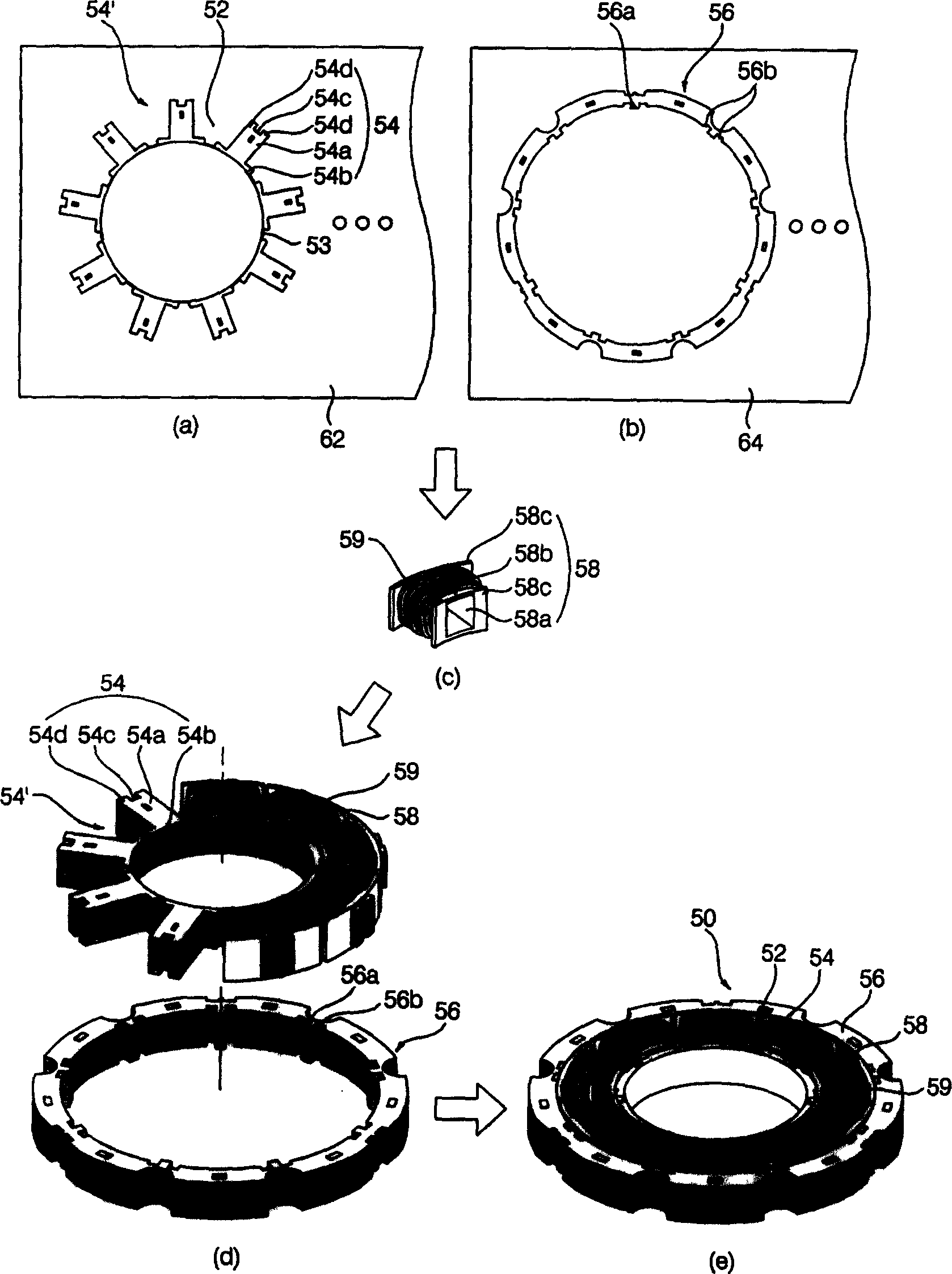

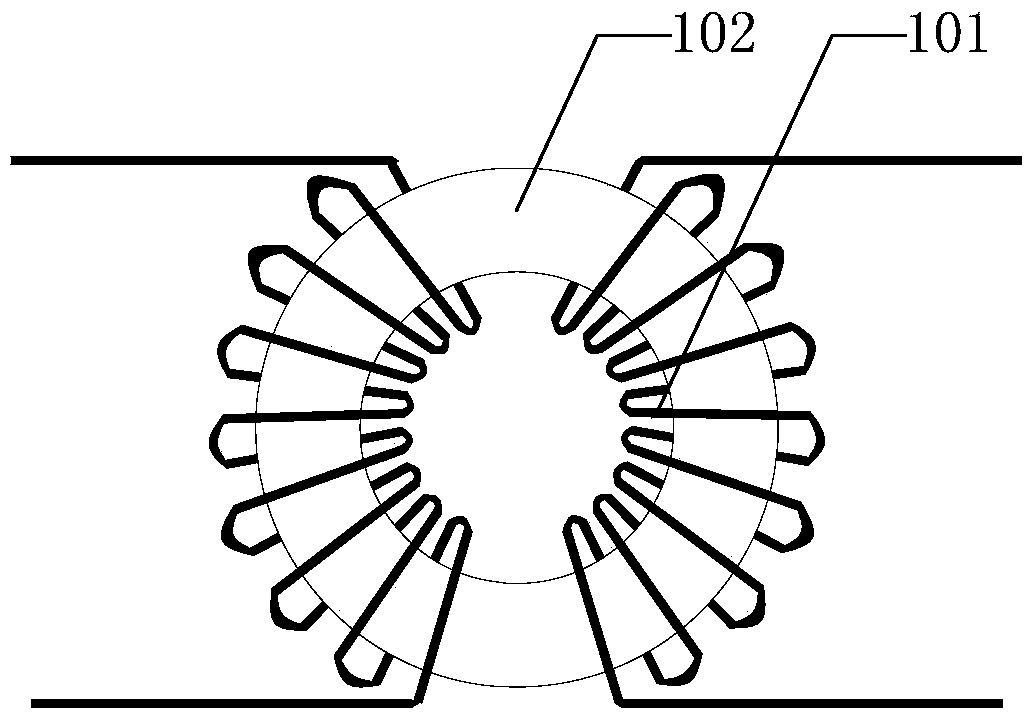

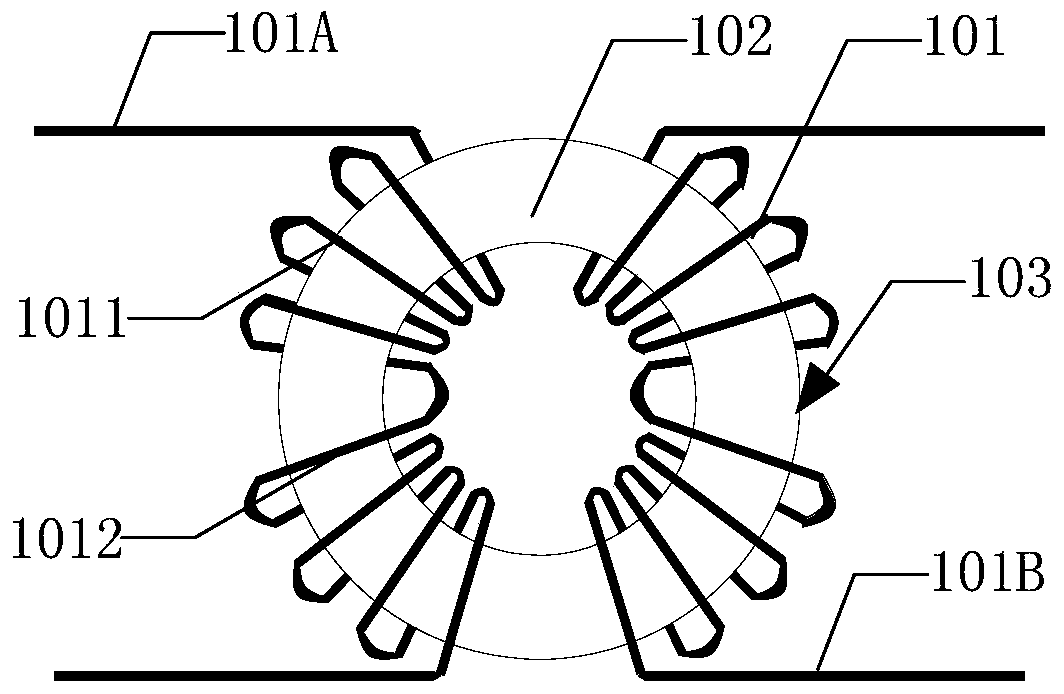

An end insulation assembly of a direct-wound motor stator

PendingCN109217522AUnique designFlexible disassemblyWindings insulation shape/form/constructionEngineeringMechanical engineering

The invention discloses an end insulation assembly of a direct-wound motor stator, belonging to the motor stator technical field. Which is composed of two coil insulating brackets and coil protectionend caps installed to at least one coil insulating bracket, The end cover is composed of two half ring sheets. Each coil insulating bracket comprises an outer wall part, a plurality of inner wall parts and a plurality of winding supporting parts. There are notches between adjacent inner wall parts, and the head ends of the inner wall parts are tongue tips. The outer facades of adjacent inner wallparts near the notches are respectively provided with protrusions and guide slots formed between the protrusions. A plurality of stoppers and a notch located between adjacent stoppers are formed on the inner edges of the two half-ring segments. The outer wall part is symmetrically provided with a mounting groove and a buckle hole between the mounting grooves, and the outer edge of each half ring piece is provided with a clamp pin and a latch pin; The stopper extends between the head ends of adjacent inner wall portions, and the notch accommodates the head ends of the inner wall portions. The assembly of the invention is not only convenient to disassemble and deform, but also prevents the stator winding from collapsing and the wire at the end of the stator winding from being exposed to theoutside of the assembly.

Owner:浙江迪贝电气股份有限公司

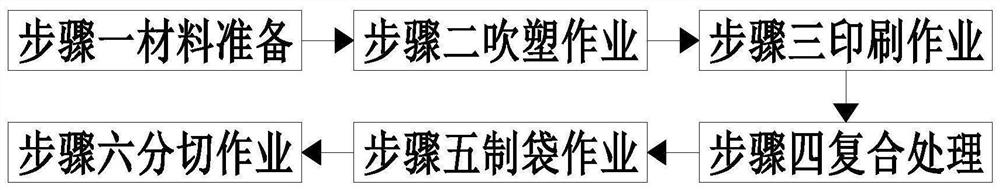

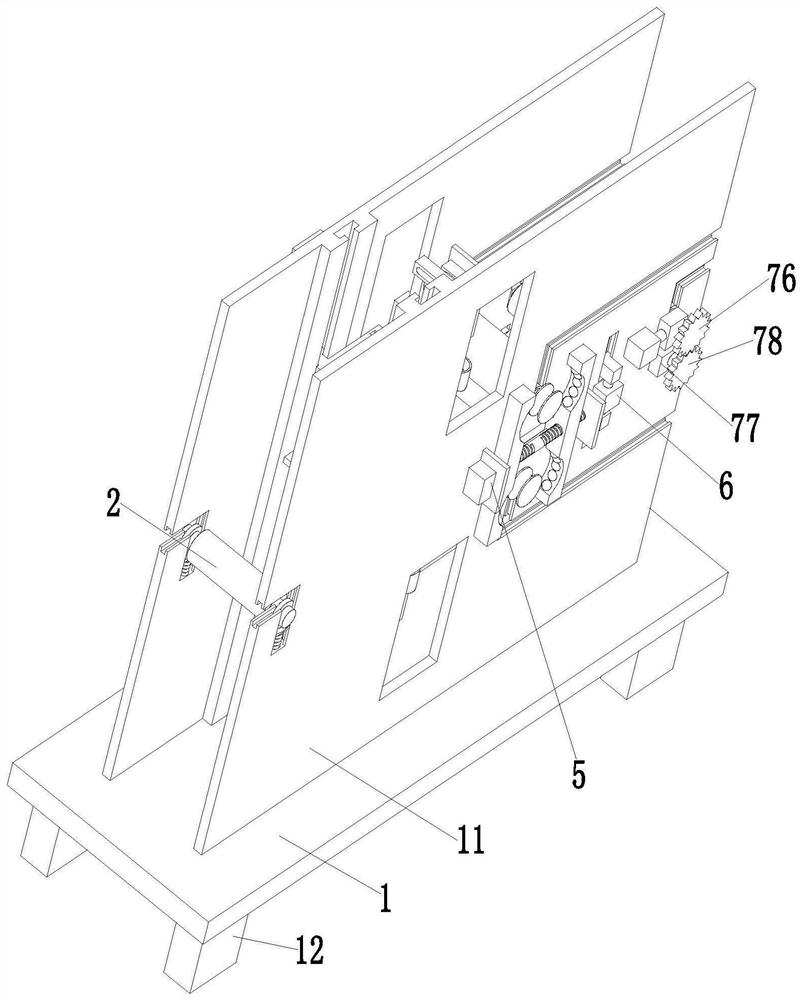

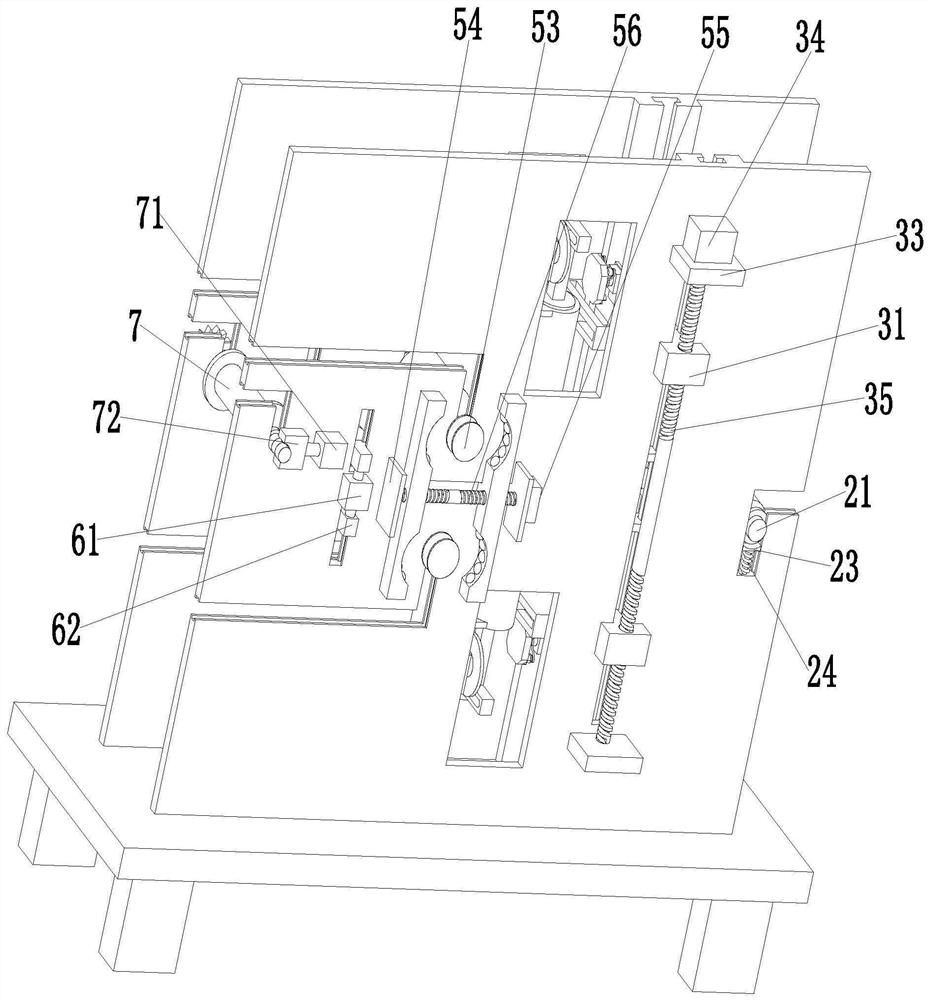

Production process of degradable paper-plastic packaging bag

InactiveCN112339344AImprove compounding efficiency and qualityGuaranteed cleanlinessBag making operationsPaper-makingAdhesive glueProcess engineering

The invention relates to a production process of a degradable paper-plastic packaging bag. The production process mainly comprises the following steps of material preparation, blow molding operation,printing operation, composite treatment, bag making operation, slitting operation and other various procedures. A paper-plastic bag composite device comprises a bottom plate, a roll feeding device, acleaning device, a glue spraying device, an unwinding device, an abutting device and a winding device. The production process can solve the following problems existing during compounding of an existing degradable paper-plastic packaging bag that a, during compounding of a traditional paper-plastic packaging bag, due to the fact that glue spraying is not uniform, the utilization rate of the glue isreduced, the compounding quality of the paper-plastic packaging bag is poor, raw materials of the paper-plastic packaging bag are wasted, and the production efficiency of the paper-plastic packagingbag is affected; and b, during compounding of the existing paper-plastic packaging bag, compounding deviation often occurs, the compounding quality of the paper-plastic packaging bag is reduced, the production quality of the paper-plastic packaging bag is further affected, and the compounding efficiency and quality of the paper-plastic packaging bag can be improved.

Owner:马婧

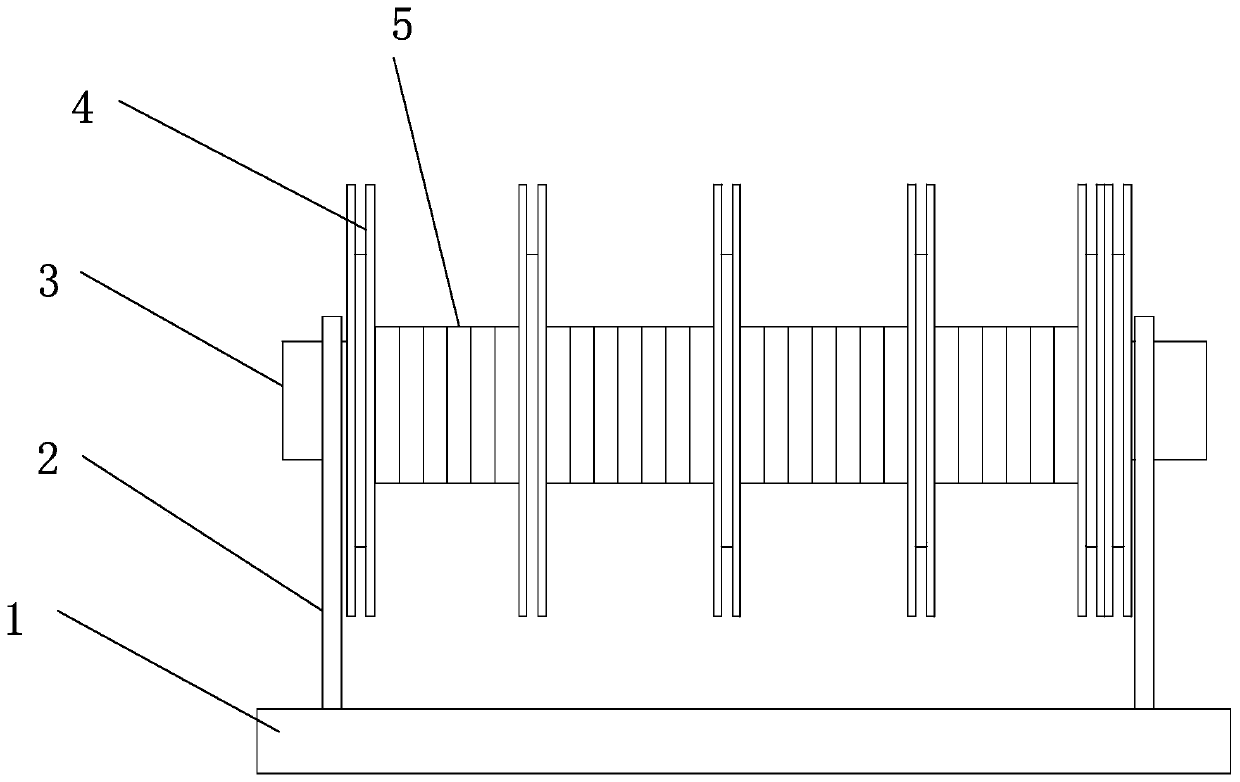

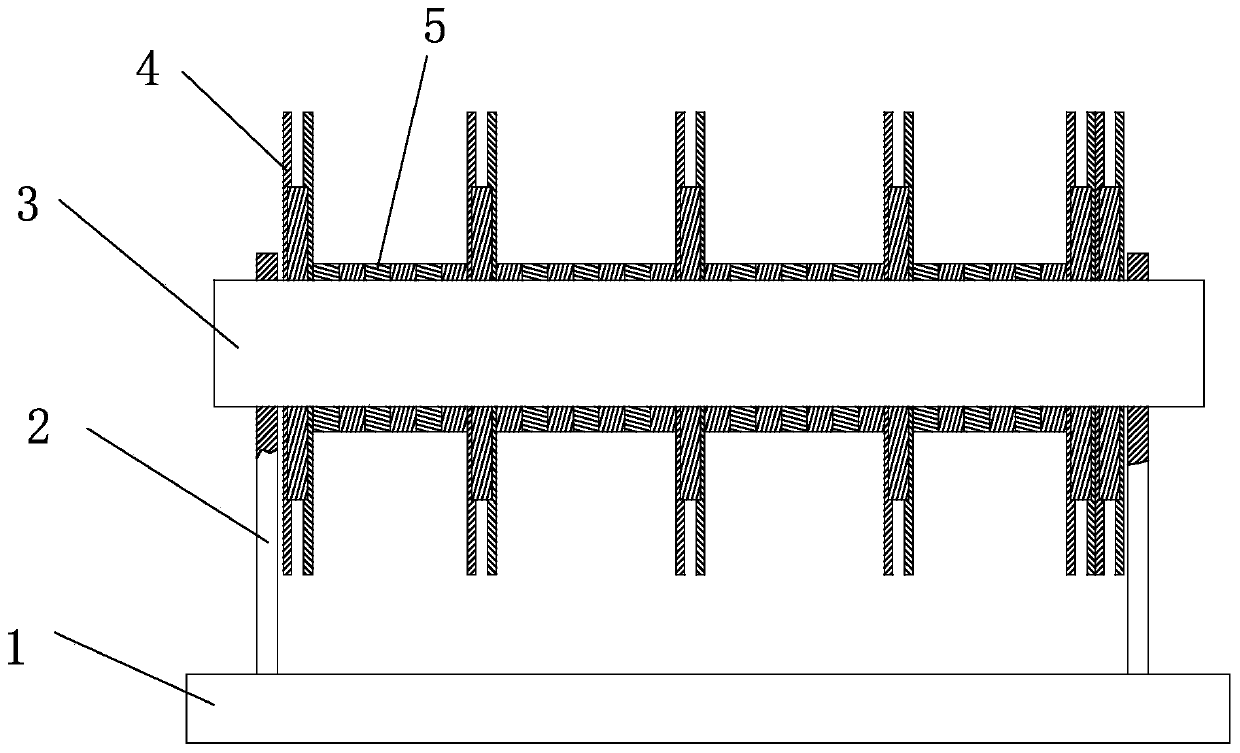

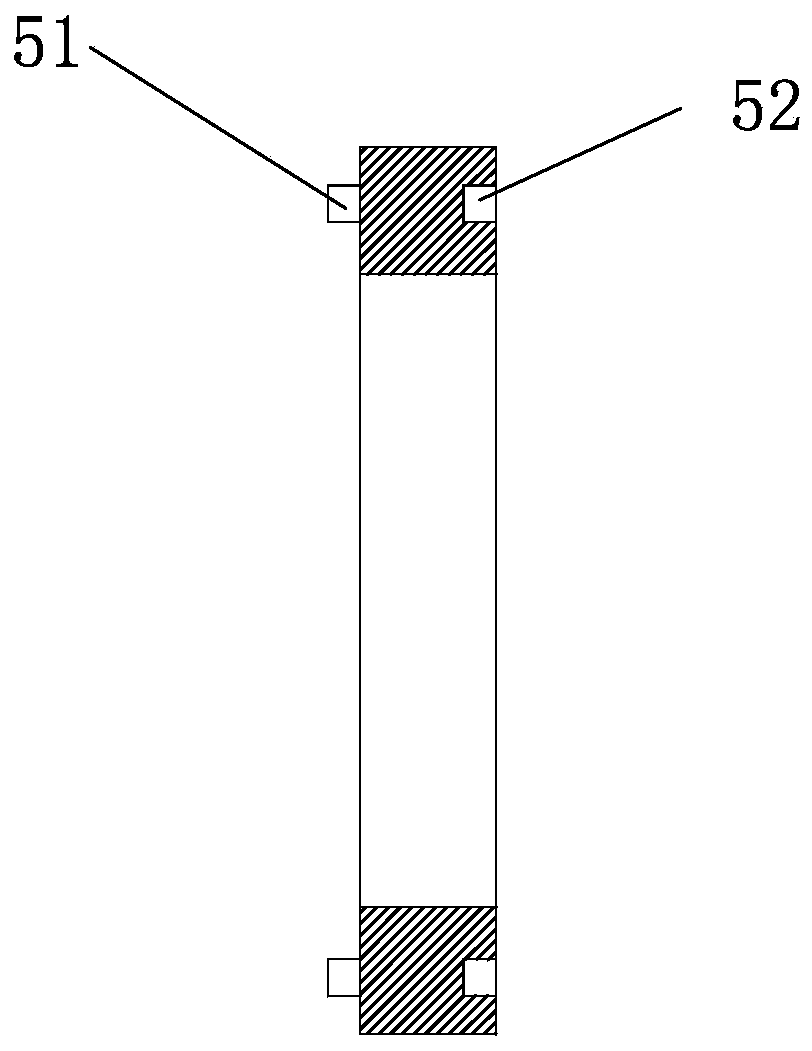

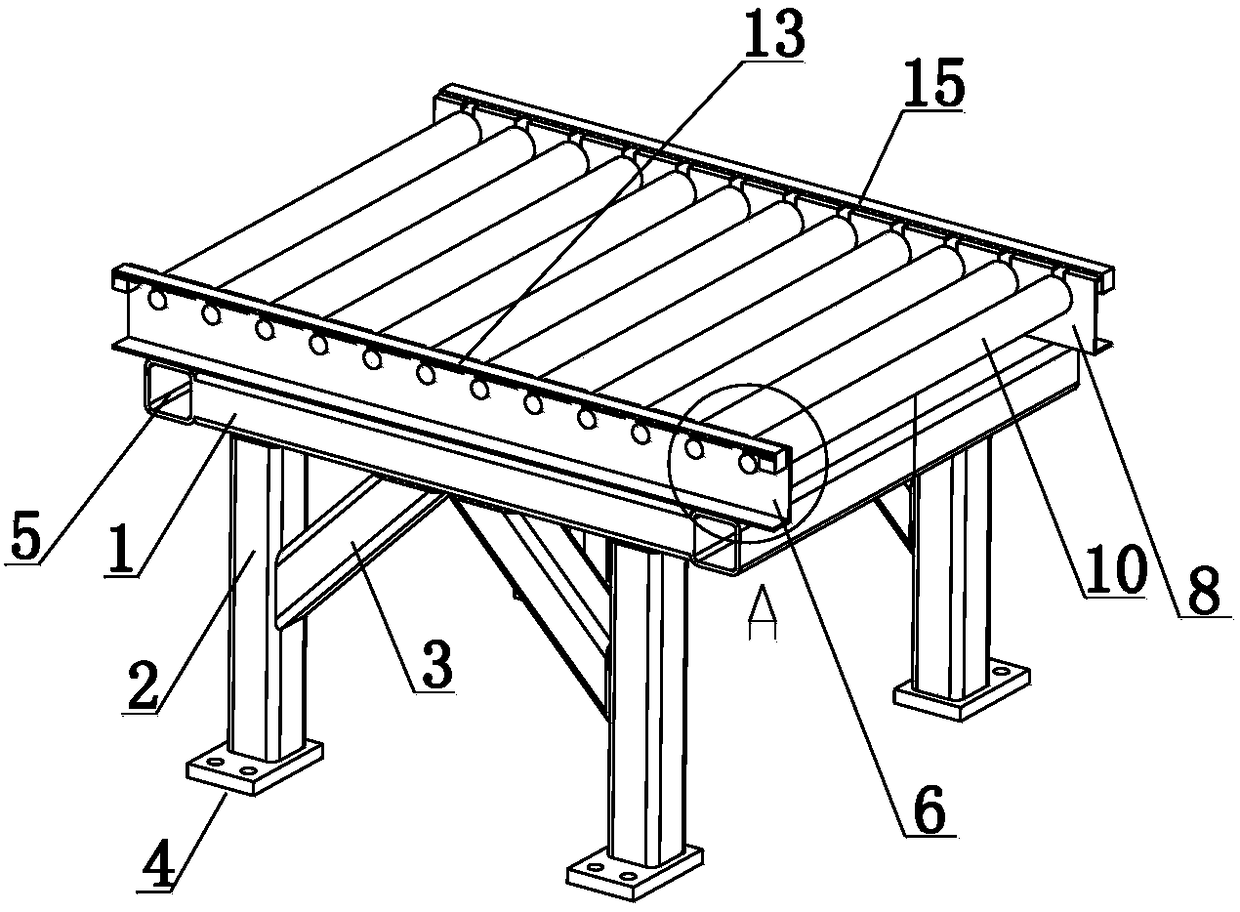

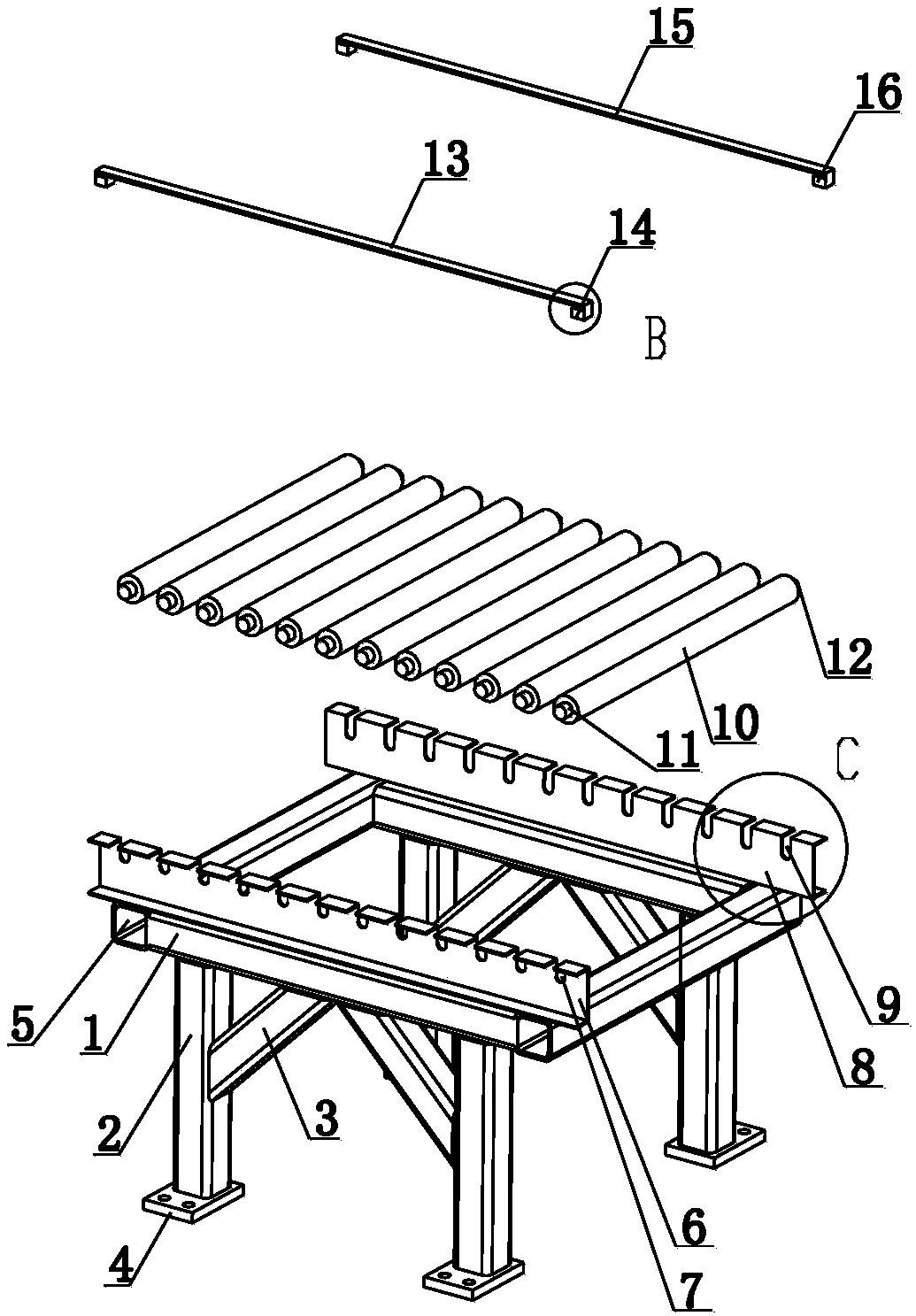

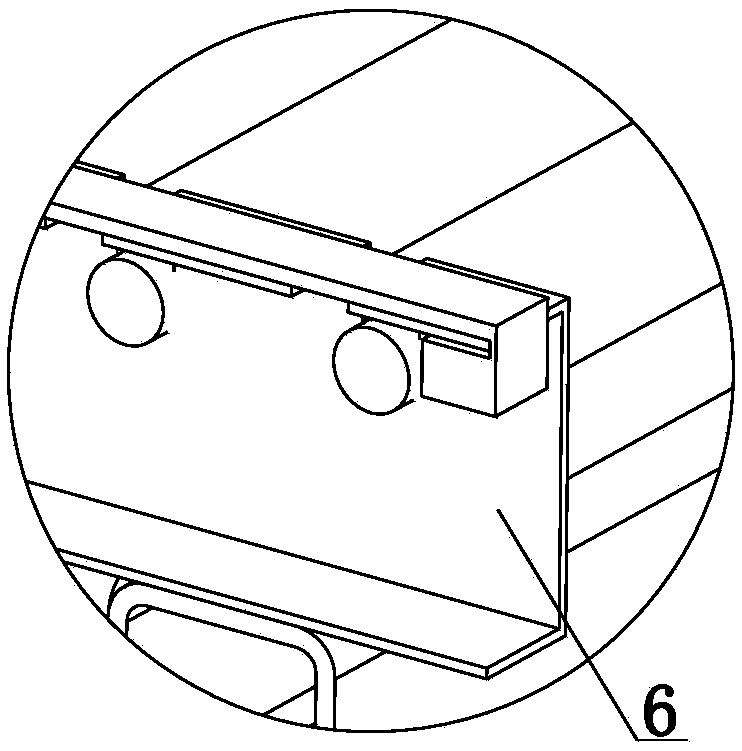

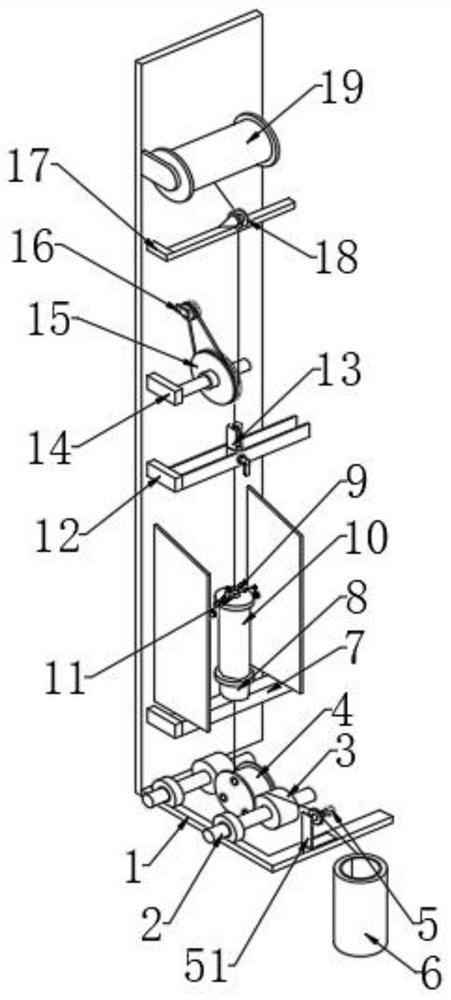

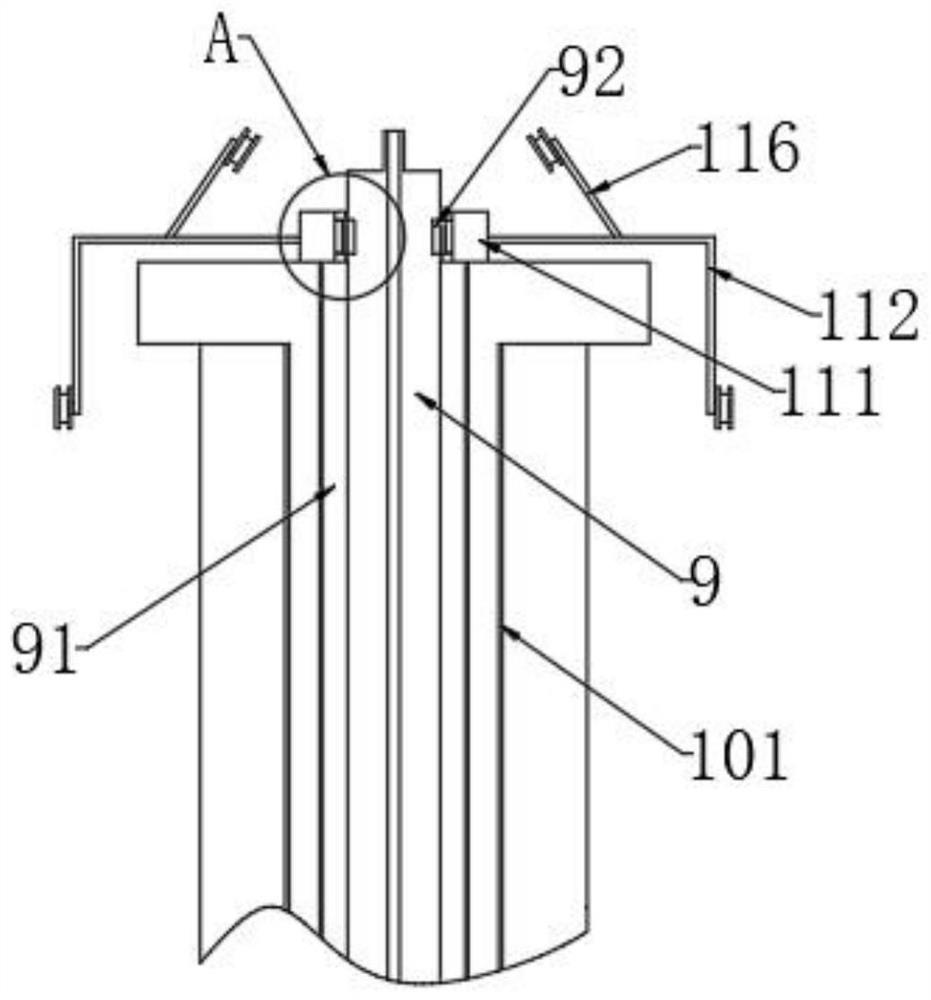

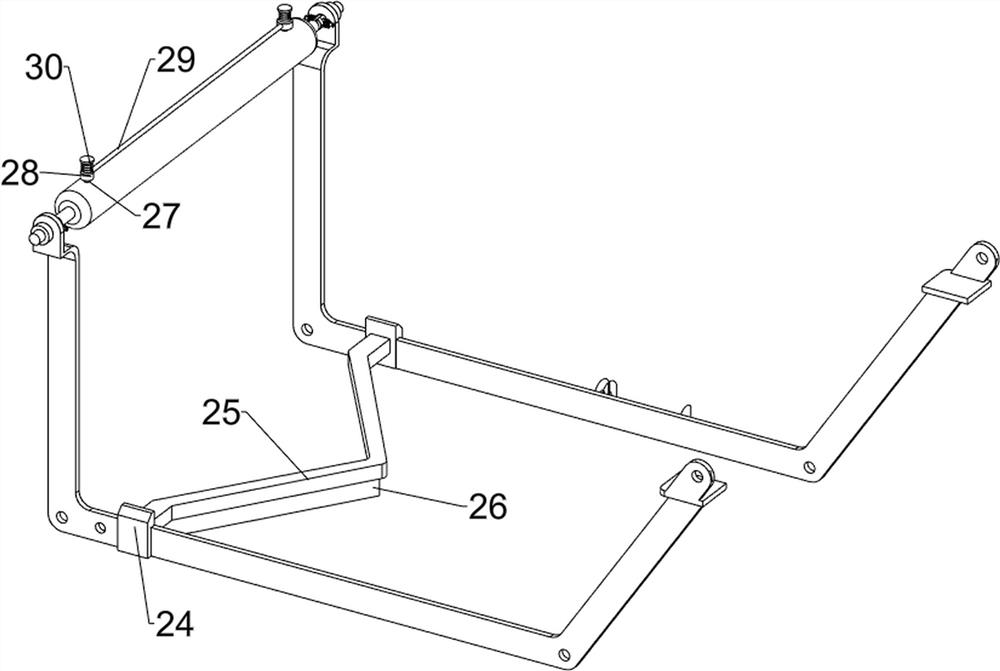

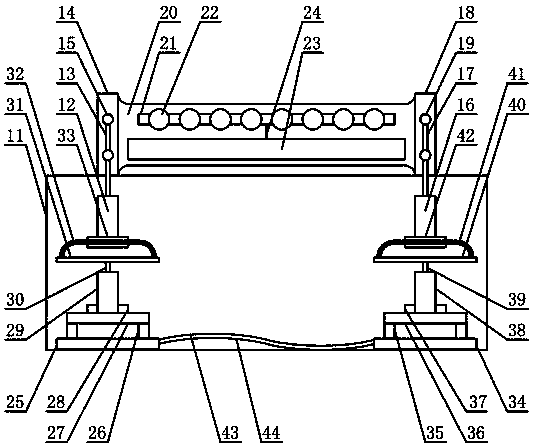

Winding device for laver culture net

The invention discloses a winding device for a laver culture net. The winding device for the laver culture net comprises a support, wherein the support comprises a pair of top pipes; support pipes arearranged on the lower parts of two ends of the top pipes; a side pipe is arranged between the upper end of each support pipe and the bottom end of each top pipe; a bottom plate is arranged at the bottom end of each support pipe; butt-joint pipes are arranged between two ends of the top pipes; a first stop frame is arranged on one side of the top part of the support; a plurality of first stop slots are formed in the upper part of the first stop frame; a second stop frame is arranged on the other side of the top part of the support; a plurality of second stop slots are formed in the upper partof the second stop frame; a plurality of winding rollers are arranged between the top parts of the first stop frame and the second stop frame; first installation shafts are arranged at one ends of thewinding rollers and are clamped into the first stop slots; and second installation shafts are arranged at the other ends of the winding rollers and are clamped into the second stop slots. According to the winding device for the laver culture net provided by the invention, the laver culture net after harvesting can be conveniently winded through the winding rollers so as to be conveniently windedand operated.

Owner:朱宏洁

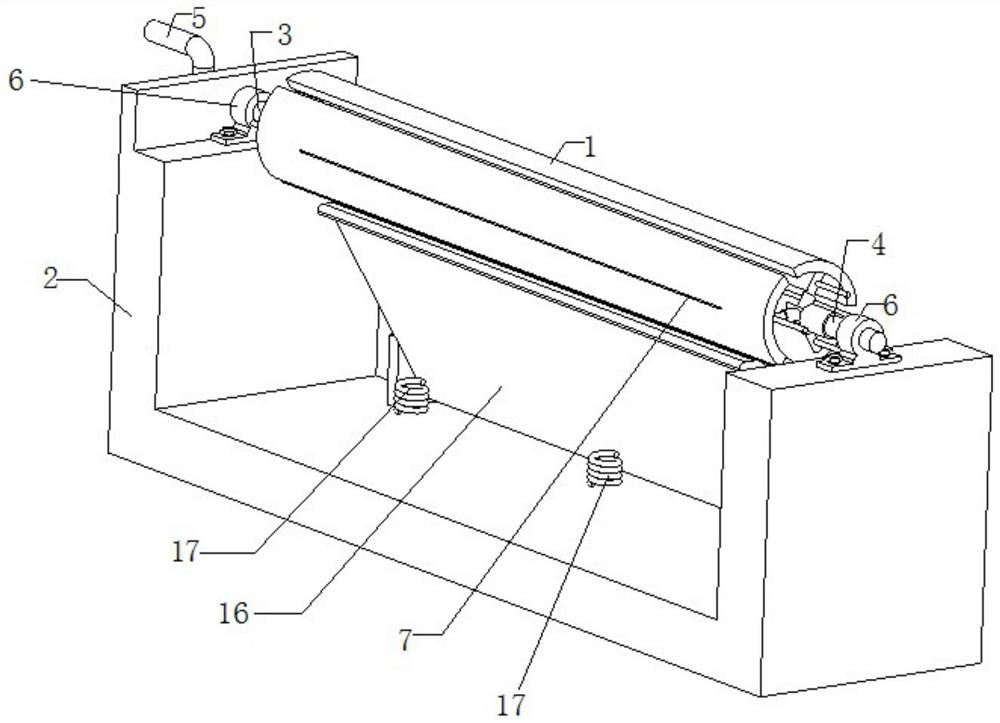

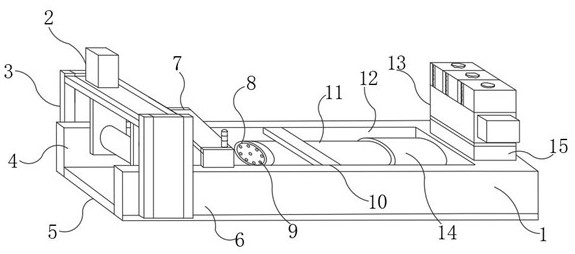

Split type textile yarn winding structure with controllable size

InactiveCN112249810AGuaranteed stable rotationConvenient winding operationFilament handlingElectric machineryTextile yarn

The invention discloses a split type textile yarn winding structure with a controllable size. The split type textile yarn winding structure comprises a winding structure body, a main support, a motor,a rotating shaft, a first clamping cover, an auxiliary support, a rotating frame, a second clamping cover, a winding drum, a screw rod and a bearing, wherein the main support is arranged on the winding structure body, the motor is fixed on the outer side of the main support, the auxiliary support is fixed on the other side of the main support through a bolt, mounting grooves are formed in the inner sides of the first clamping cover and the second clamping cover, the inner diameter of the mounting grooves is larger than the diameter of the outer end of the winding drum and the diameter of a flange, the diameter of the outer end of the winding drum is the same as the diameter of the flange, and meanwhile, through holes are formed in the middle parts of the winding drum and the flange in a penetrating mode. According to the split type textile yarn winding structure with the controllable size, an existing yarn winding structure is improved, so that winding drums with different sizes can be clamped and fixed according to use requirements, shaking is avoided when the winding drum rotates, and stable winding operation of yarns is facilitated.

Owner:何林峰

Synchronous winding equipment for back-twist copper foil wires and application method thereof

The invention discloses synchronous winding equipment for back-twist copper foil wires and an application method thereof, and belongs to the field of copper foil wires. According to the synchronous winding equipment for the back-twist copper foil wires and the application method thereof, a back-twist assembly is matched with a three-groove connection main wheel and a three-groove connection auxiliary wheel to reduce the stress generated in the wrapping process of the wrapped copper foil wires, so that the twisting phenomenon of the copper foil wires is reduced, and the winding quality of the copper foil wires is improved; heat generated by friction is conducted to a sleeving ring through an L-shaped connection rod and a guide connection rod, so that a deformation memory metal ring is heated to deform; the deformed deformation memory metal ring is embedded into an embedding groove, so that the guide assembly is limited and fixed; centrifugal force can be generated in the rotating process of the guide assembly, so that the guide assembly is slowly separated from a hollow pipe along with the passing of the rotating time; and the guide assembly is limited and fixed, so that the possibility that the guide assembly is separated from the hollow pipe is reduced, and the stability of the copper wire wrapping process is improved.

Owner:东莞市正润电业科技有限公司

Automatic slitting equipment for door and window sealing rubber sheets

ActiveCN114670275ATransmission controlConvenient winding operationMetal working apparatusElectric machineryKnife blades

The automatic slitting equipment comprises a movable supporting frame, positioning sliding blocks, a two-way motor and a water tank, the inner side of the movable supporting frame is rotationally connected with a slitting shaft, slitting blades are arranged on the outer portion of the slitting shaft at equal intervals, and positioning frames are symmetrically fixed to the two sides of the outer portion of the movable supporting frame; the positioning sliding block is embedded in the movable supporting frame, a rotating rod is rotationally connected to the outer side face of the movable supporting frame, a transmission gear is fixedly installed on one side of the rotating rod, the bidirectional motor is fixedly installed on the inner side of the movable supporting frame, and the output ends of the two sides of the bidirectional motor are both connected with driving shafts; the water tank is fixedly installed in the upper end of the movable supporting frame in an embedded mode. The automatic slitting equipment for the door and window sealing films is provided with a stable transmission structure for controlling the cut sealing films, and is provided with a cutting structure cooling structure, so that the cutting processing effect of the cutting structure on the sealing films is kept.

Owner:临朐瑞星塑胶制品有限公司

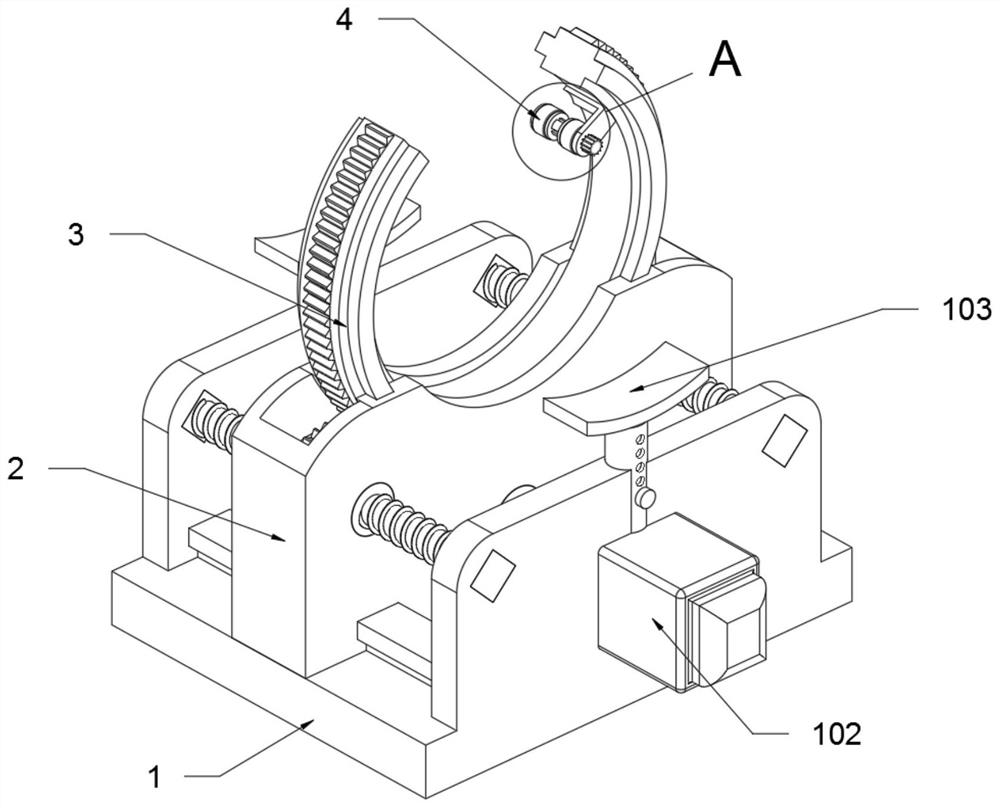

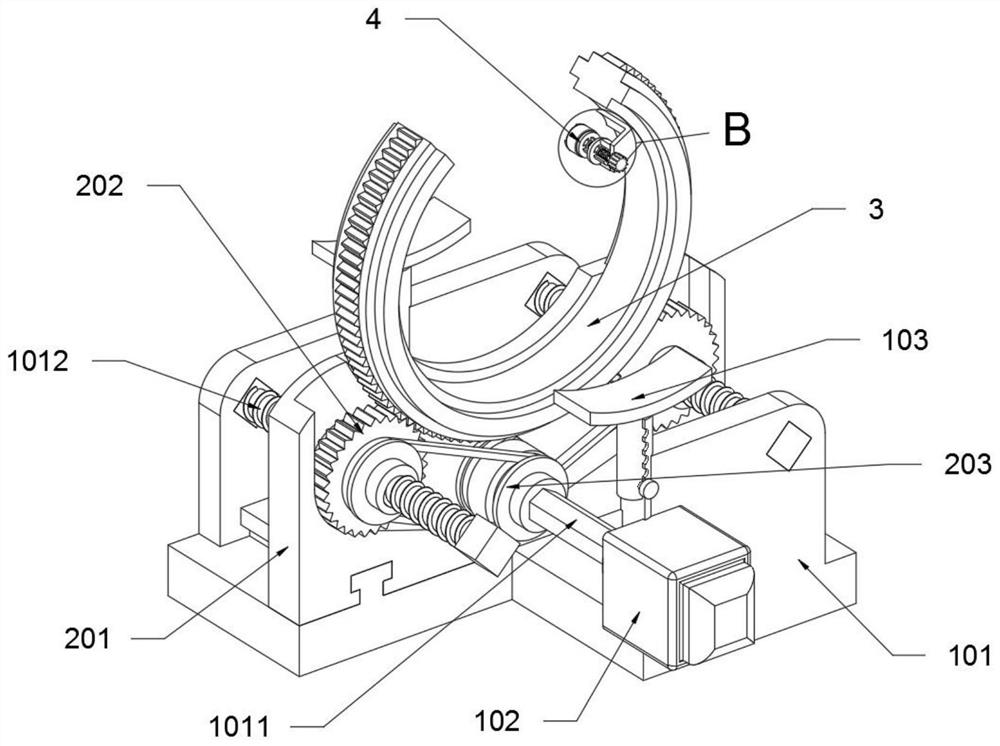

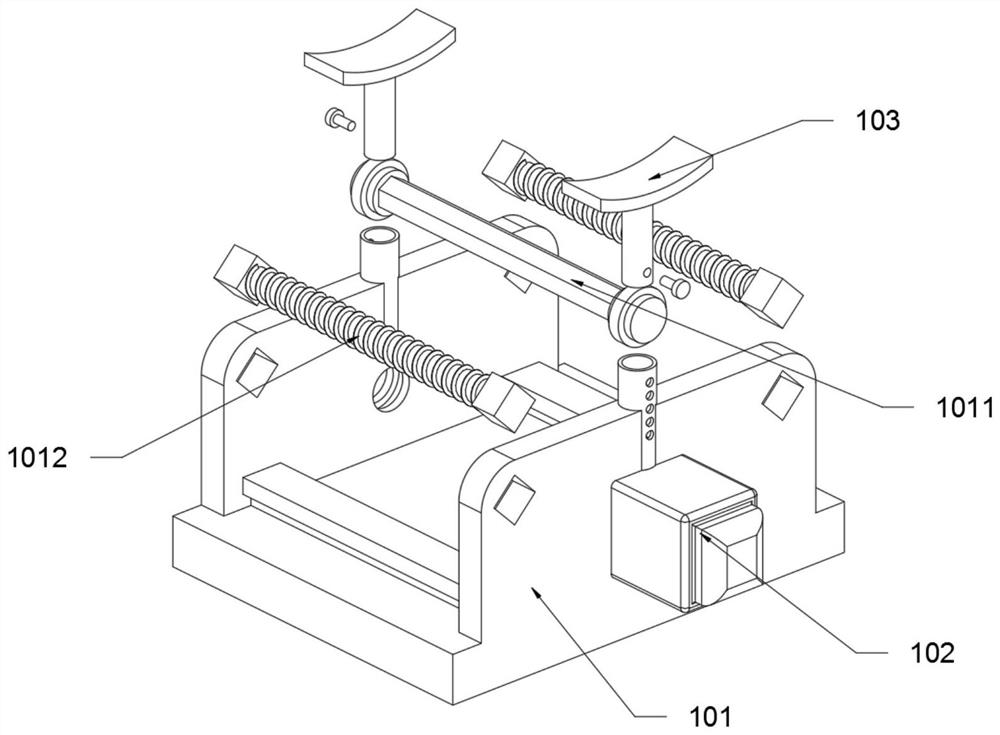

Bandage quick dressing change auxiliary device for medical care

The invention discloses a bandage quick dressing change auxiliary device for medical care, relates to the technical field of medical care, and solves the problems that the operation of manually and circularly winding and binding a bandage in the prior art is troublesome and low in efficiency, and the tightening force is not uniform when the bandage is wound, the bandage quick dressing change auxiliary device comprises a winding ring; and the winding ring is inserted into the movable shell. A winding ring of the device can automatically wind a bandage outside a bandage damping assembly around an affected part of a patient under the cooperation effect of a driving motor and a moving assembly, operation is convenient, bandage winding does not need manual operation, the moving assembly can automatically move while the bandage is wound through the winding ring, wound dressing change nursing can be carried out on wounds with different lengths, the adaptability is high, the tightening force of the bandage can be adjusted through the bandage damping assembly, and therefore the winding force of the bandage is uniform and stable.

Owner:朱鹏豫

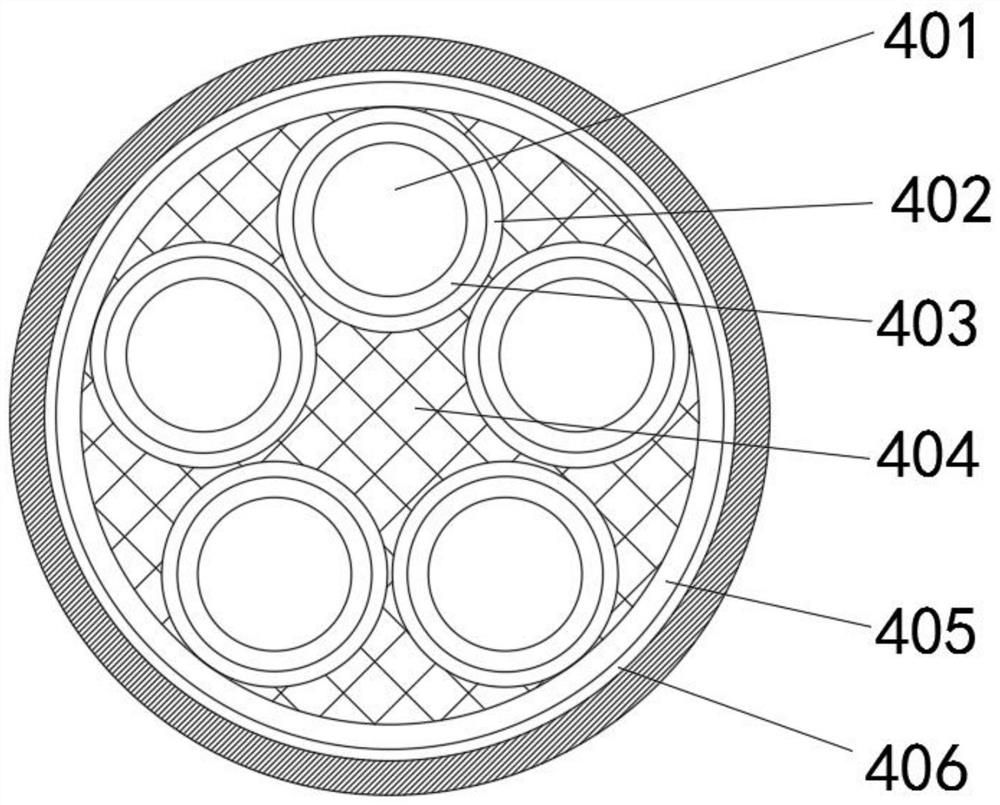

High-safety low-release halogen-free low-smoke B1-level fire-resistant cable

PendingCN112201402AImprove securityAvoid discharge in the air gapFlexible cablesCable/conductor manufactureEngineeringMaterials science

The invention discloses a high-safety low-release halogen-free low-smoke B1-level fire-resistant cable, which comprises five groups of conductors, an insulating layer, a mica fire-resistant layer, a glass fiber filling layer, a glass fiber wrapping tape and an insulating sheath, wherein the mica fire-resistant layer is wound on the outer surface of the side edge of each conductor, the insulating layer is sleeved on the outer surface of the mica fire-resistant layer, the glass fiber wrapping tape is wound on the outer surface of the side edge of the insulating layer, the glass fiber filling layer is filled between the glass fiber wrapping tape and the insulating layer, and the outer surface of the side edge of the glass fiber wrapping tape is fixedly sleeved with the insulating sheath. According to the high-safety low-release halogen-free low-smoke B1-level fire-resistant cable, the cable has a double-layer protection structure, the safety during cable bending operation is improved, theeccentric phenomenon of the cable in the coiling bending process is avoided, the hardening cracking phenomenon of the cable is prevented, the service life of the cable is prolonged, and the stabilityof the cable is improved.

Owner:ANHUI PACIFIC CABLE CO LTD

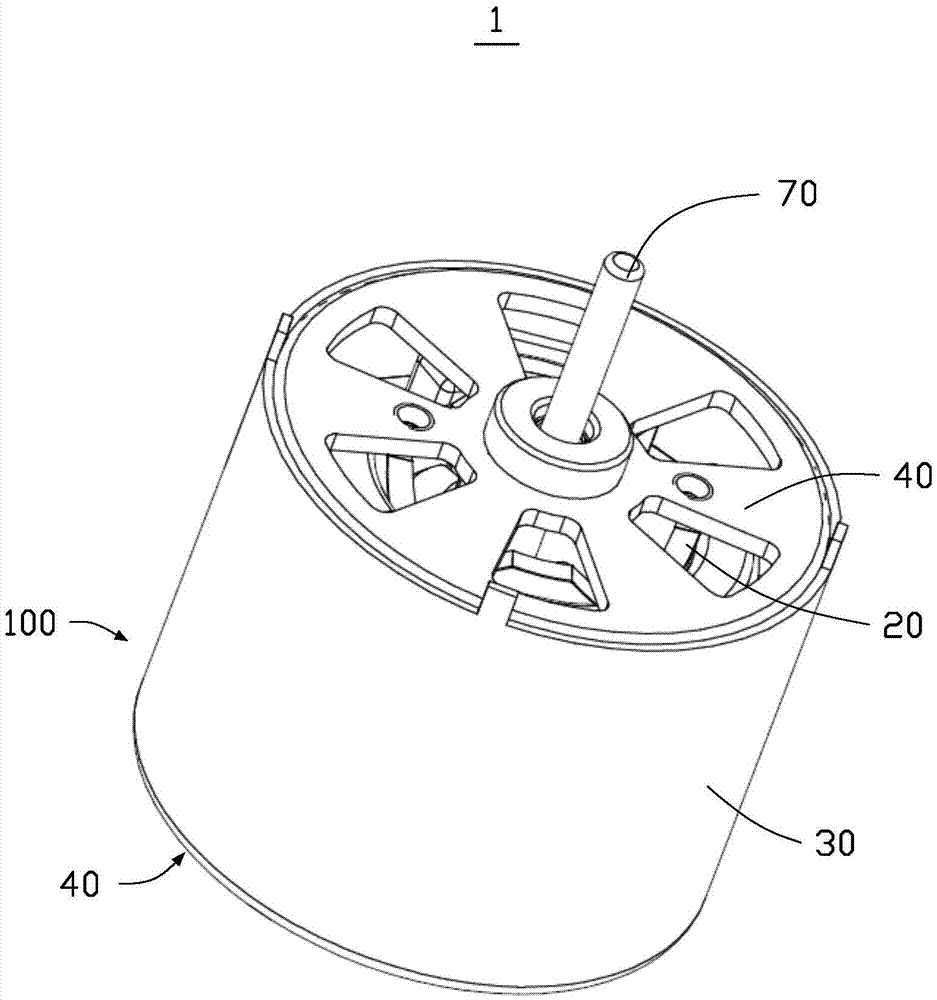

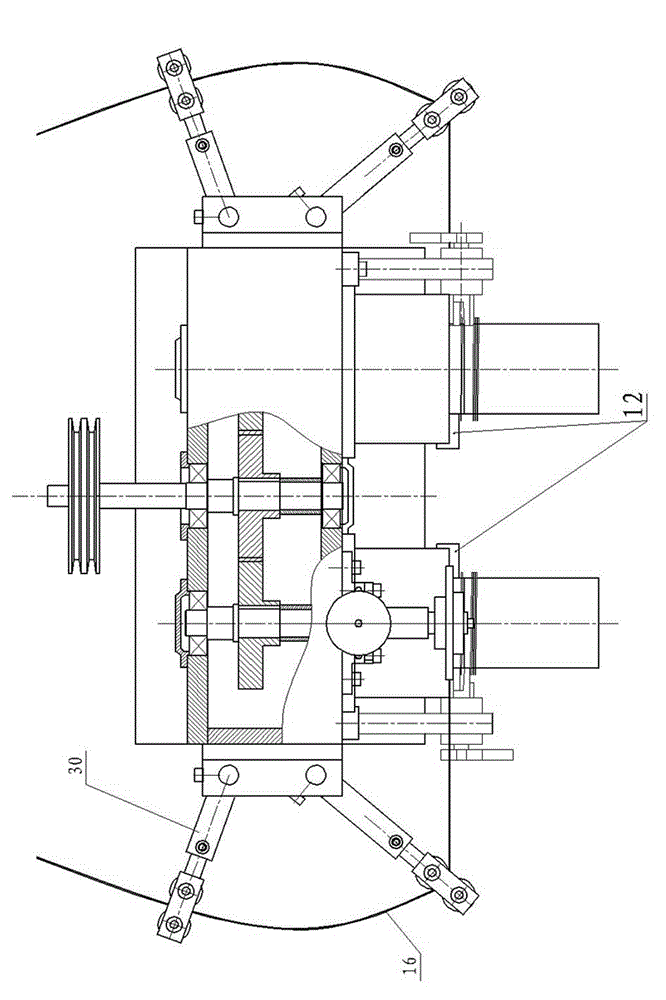

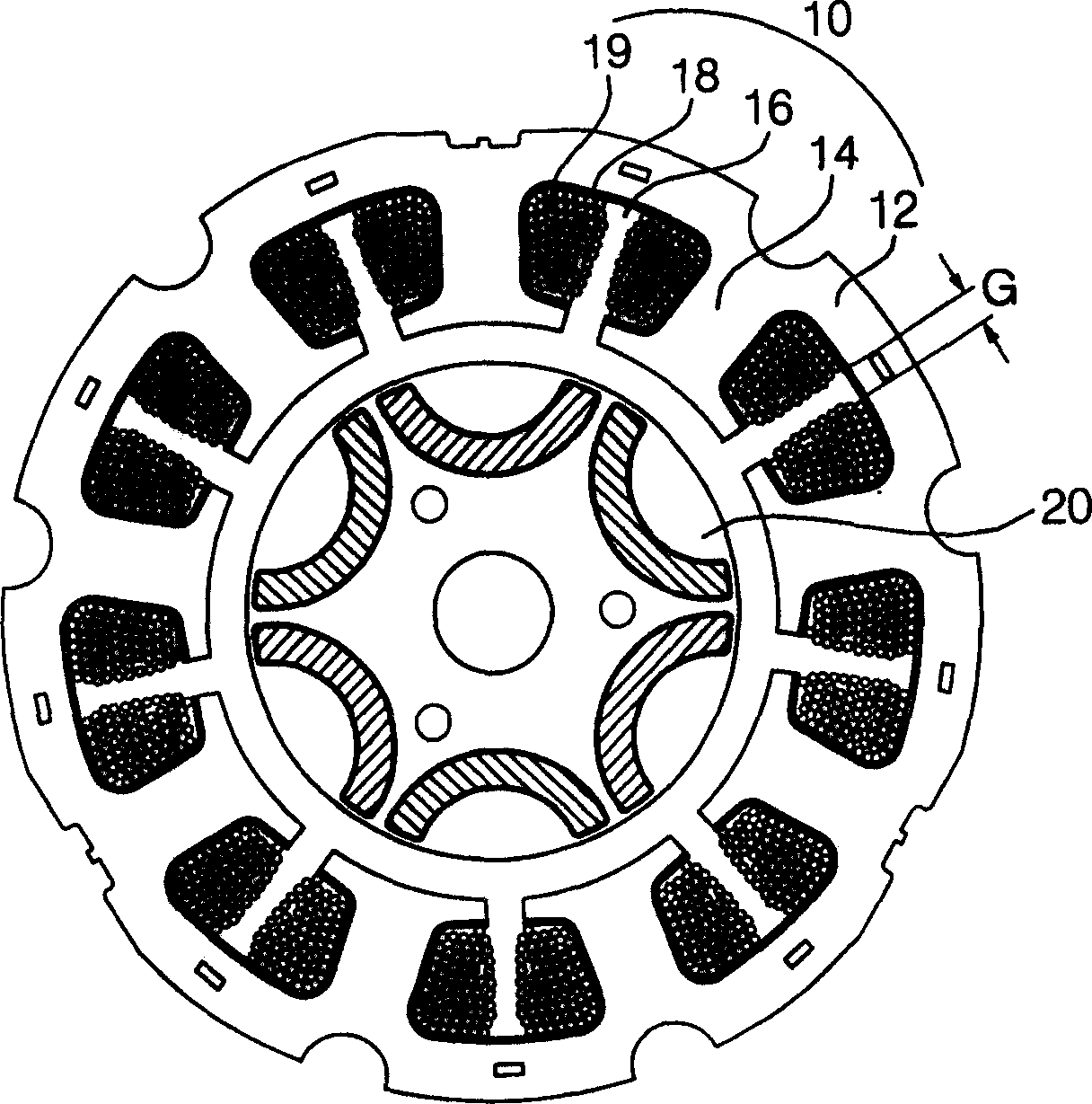

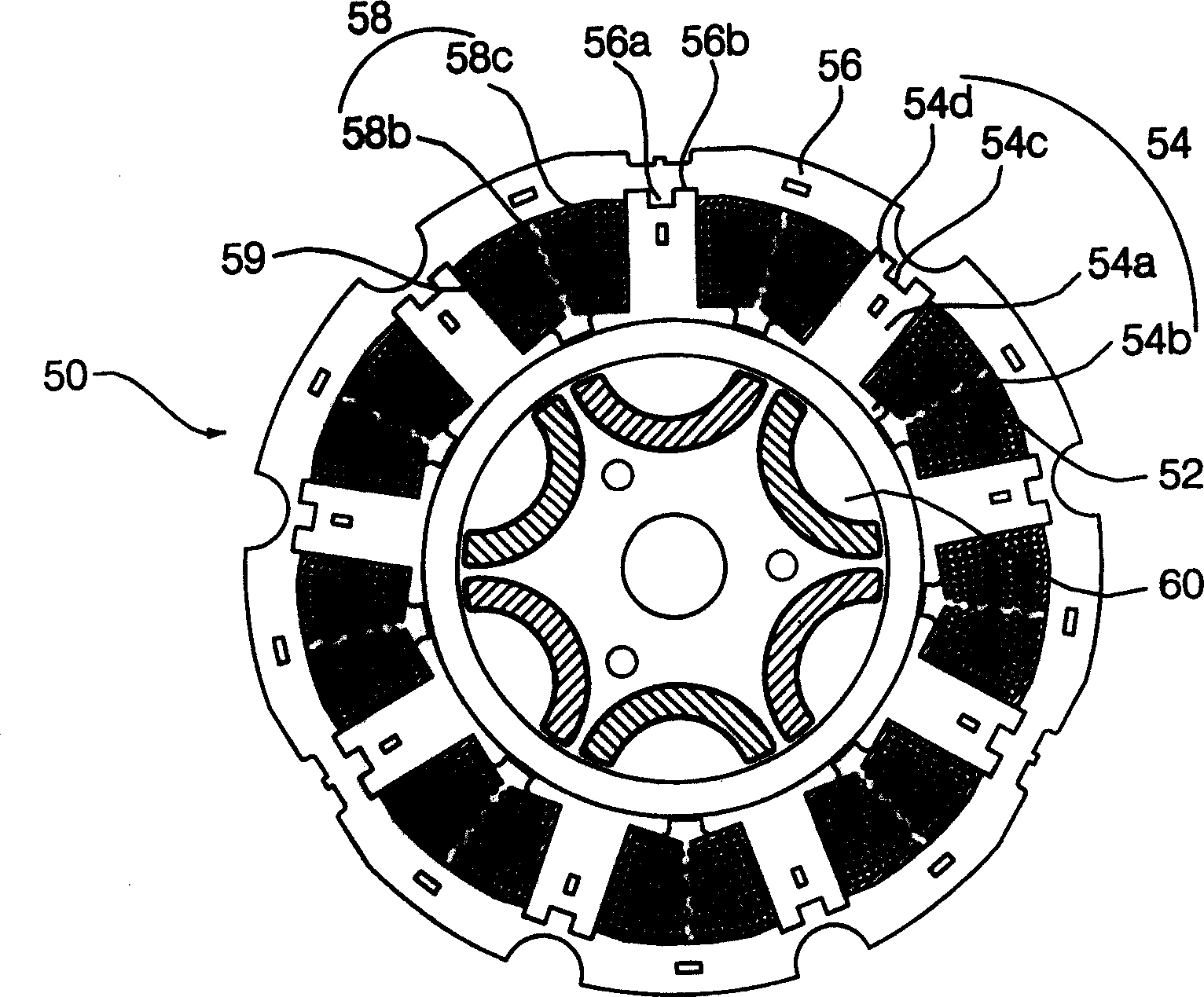

Method for forming motor stator

InactiveCN107026540AConvenient winding operationFast windingMagnetic circuitManufacturing stator/rotor bodiesBobbinEngineering

The invention relates to a method for forming a motor stator. The method includes the steps of: a) providing a plurality of plates or metal powder and forming the plates or the metal powder into a plurality of magnetic chips, wherein each magnetic chip comprises a yoke portion and a plurality of stator teeth, each of the stator teeth comprises a tooth portion and two pole shoes, and one end of one of the pole shoes extends towards the direction away from the yoke portion to form a bent portion; b) axially overlapping the plurality of magnetic chips and fixing the magnetic chips to form a stator core; c) providing a bobbin bracket, and mounting the bobbin bracket on the stator core; d) winding wires on the bobbin bracket; and e) bending the bent portions towards the direction opposite to the axial center of the stator core so that the end portions of the bent portions are leveled with the pole shoes of the neighbor stator teeth. The method makes the winding convenient and fast.

Owner:JOHNSON ELECTRIC SHENZHEN

Solar lighting tractor body

InactiveCN109177864AEasy to spreadConvenient winding operationPhotovoltaic supportsOptical signallingHydraulic cylinderDrive shaft

The invention discloses a solar lighting tractor body, comprising a main body of the solar lighting tractor body, wherein a support frame is arranged on the top surface of the main body; a rotating drum is arranged on the top of the support frame; a driven gear is arranged on the outer end of the rotating drum; a driving motor is arranged on the top surface of the support frame; a driving shaft isarranged on the front part of the driving motor; a driving gear is arranged on the outer peripheral surface of the driving shaft, and the driving gear is meshed with the driven gear; a guide drum isarranged on the front part of the main body, and a solar thin film cell is wound between the guide drum and the rotating drum; the front part of the main body is provided with a second hydraulic cylinder, and the upper part of the second hydraulic cylinder is provided with a second piston bar; the end part of the second piston bar is provided with a lifting pipe; the end part of the lifting pipe is sleeved with a lifting shaft; the end part of the lifting shaft is provided with a lamp shell; a lamp body is installed inside the lamp shell; and the lamp body and the solar thin film cell are connected through a cable. The solar lighting tractor body can flexibly adjust the solar thin film cell, and the lighting is convenient to realize.

Owner:盐城亿恒机械制造有限公司

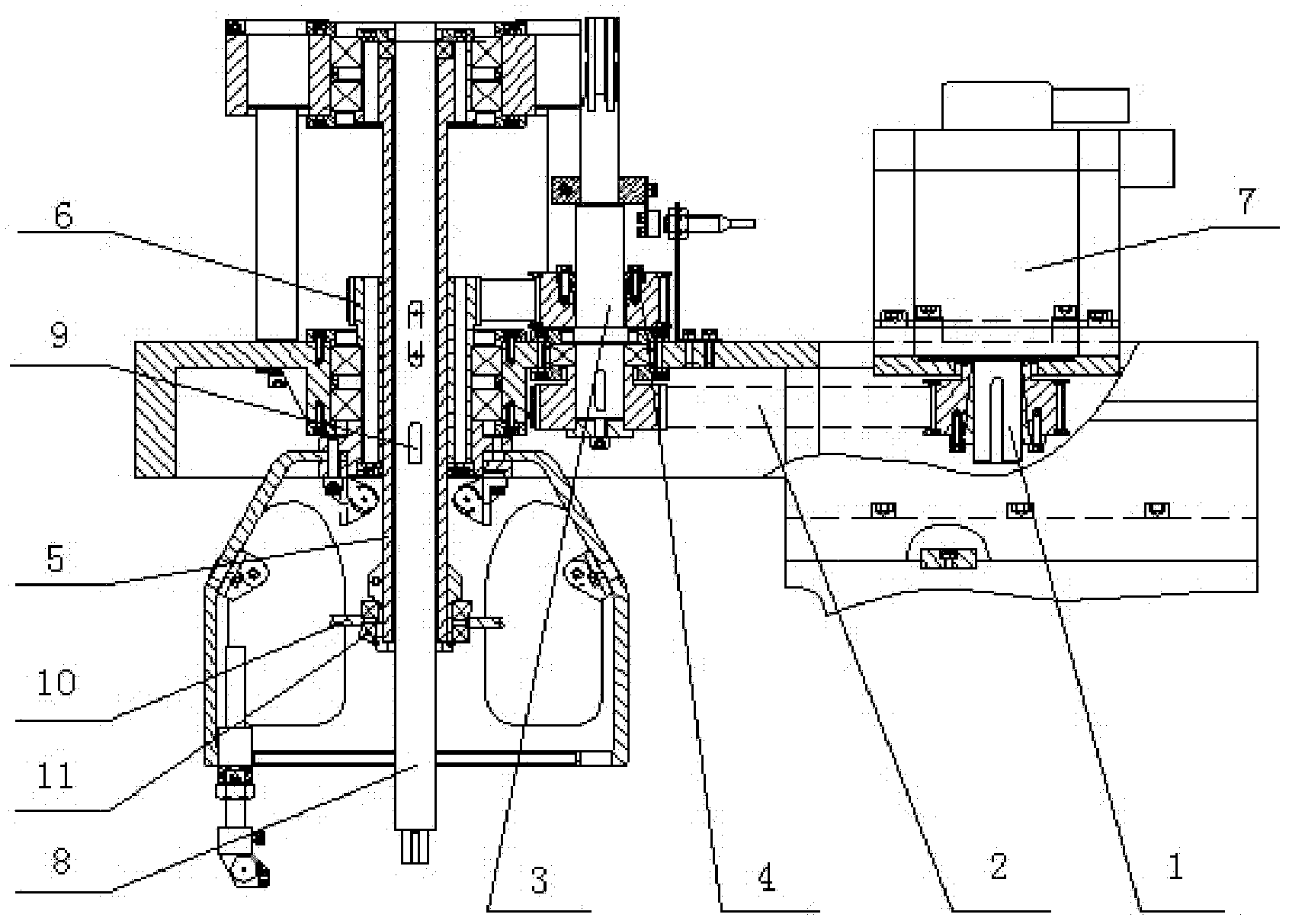

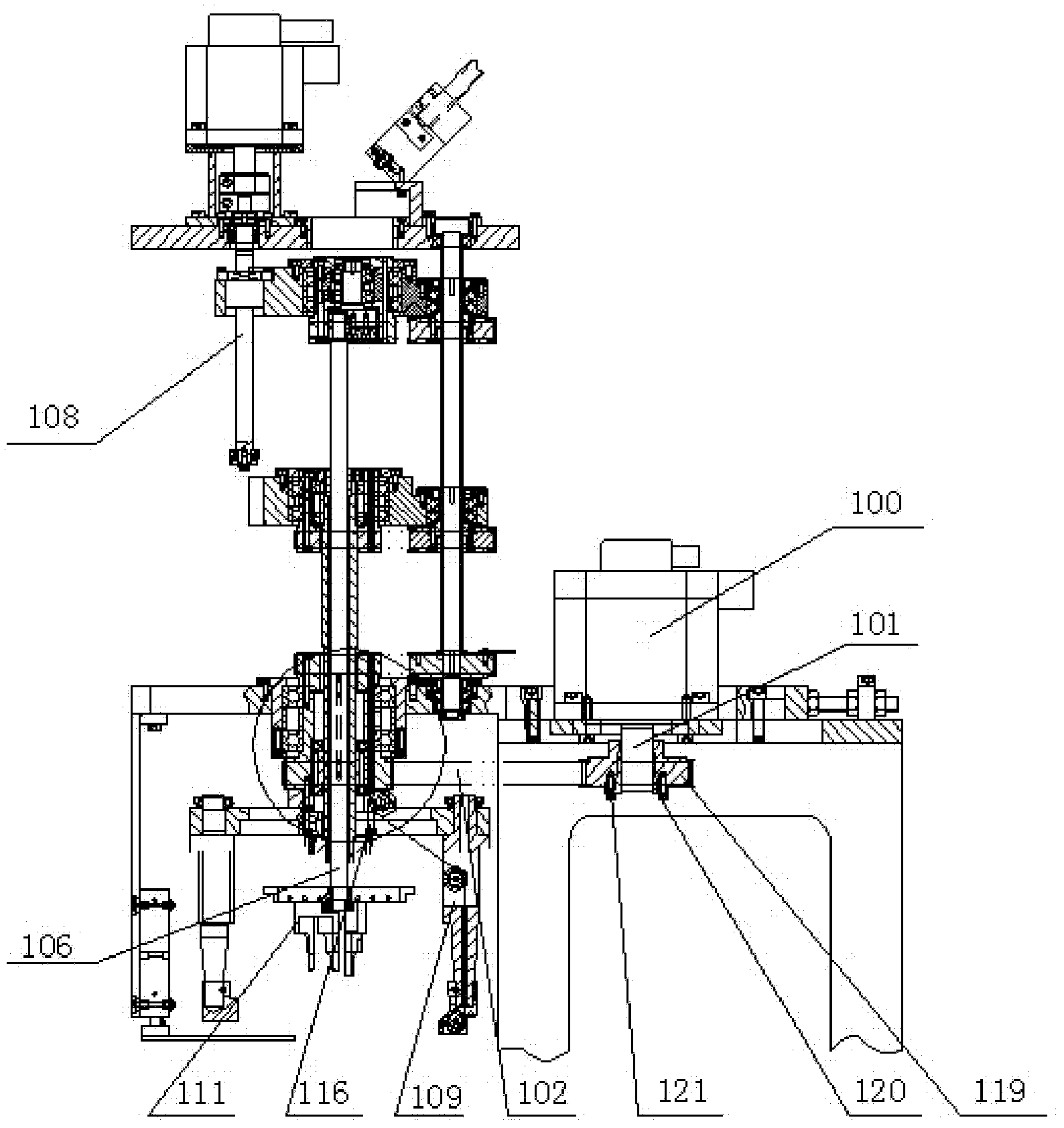

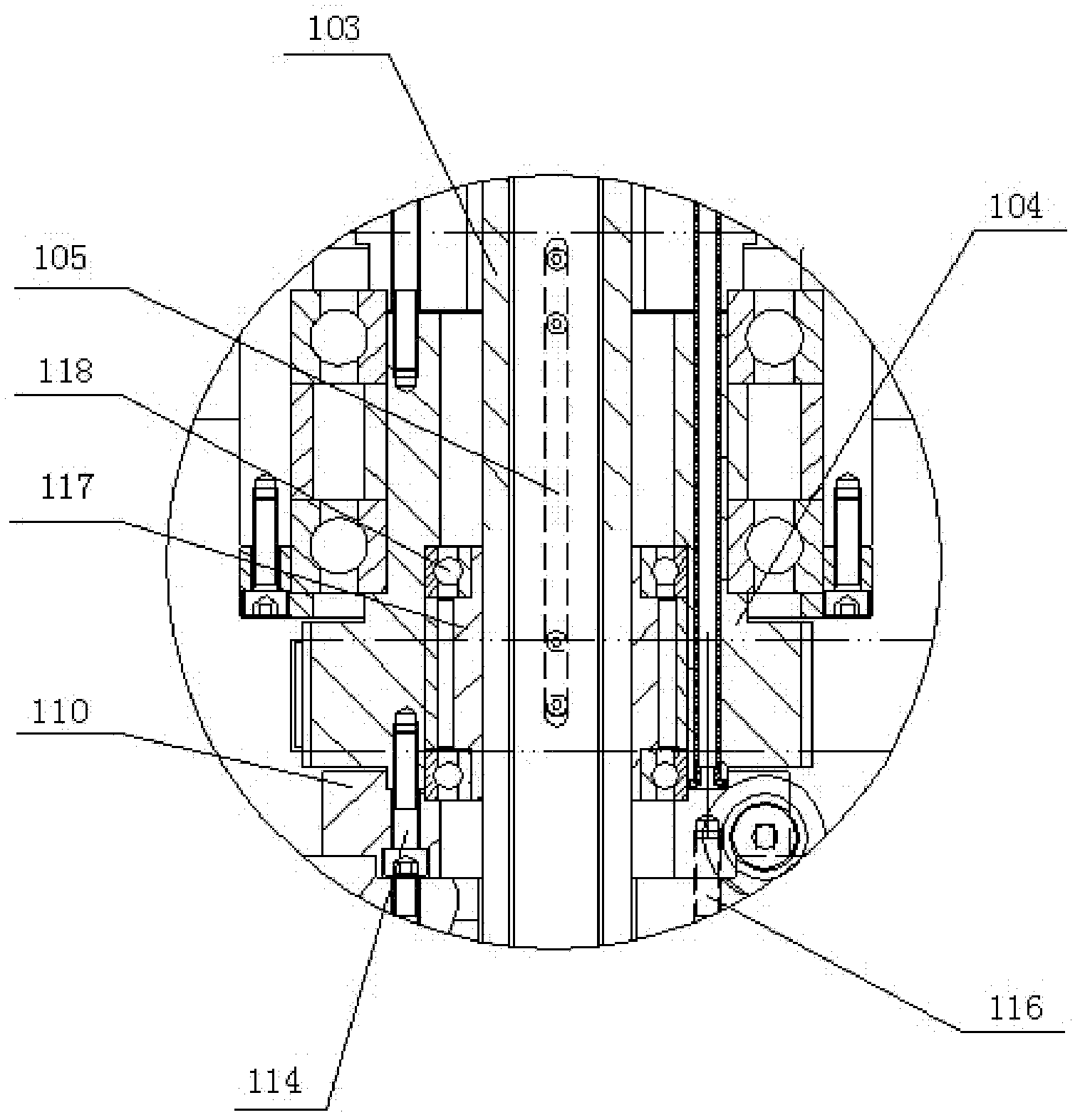

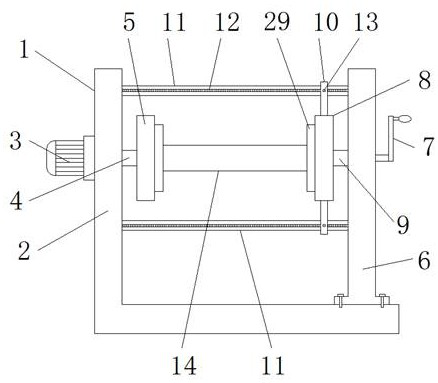

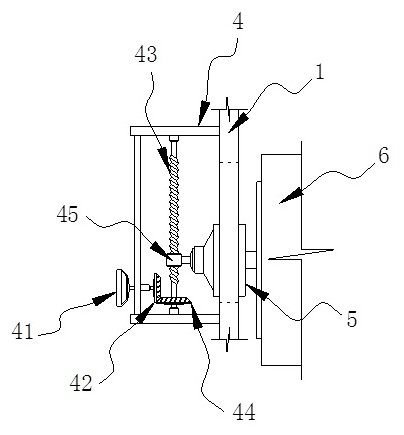

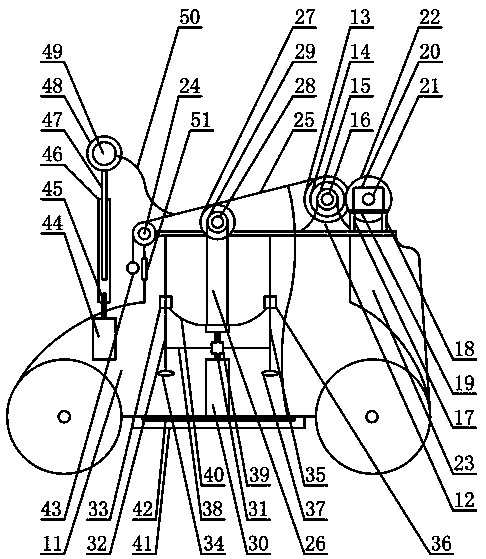

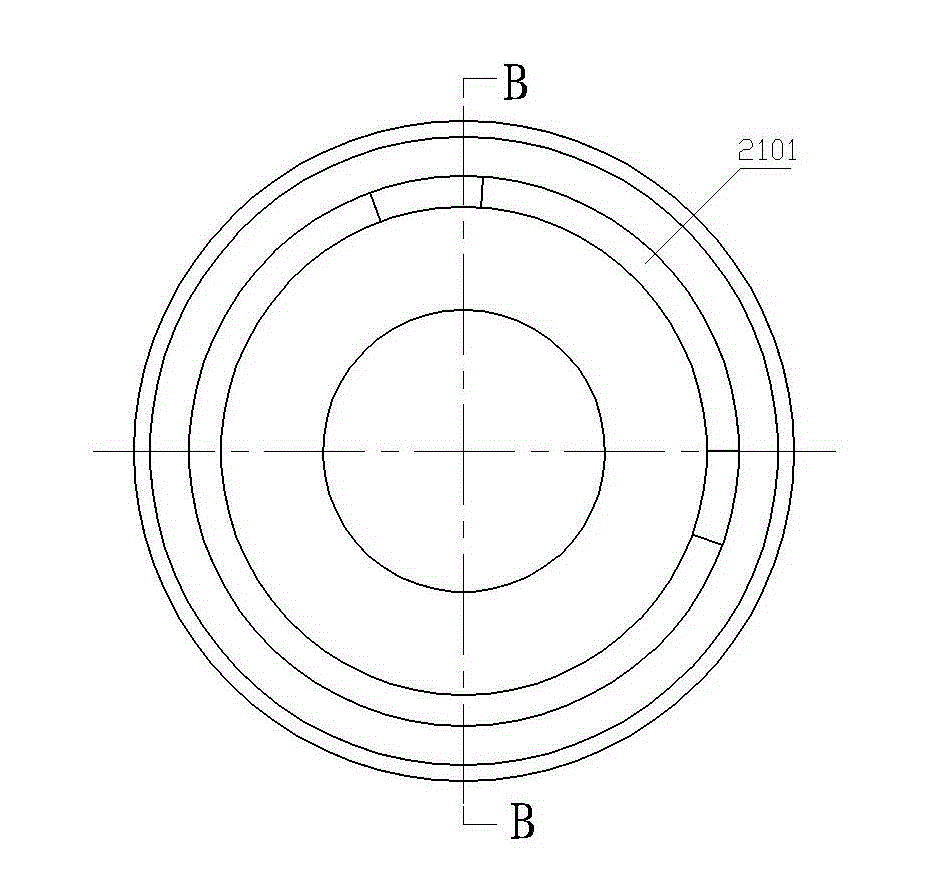

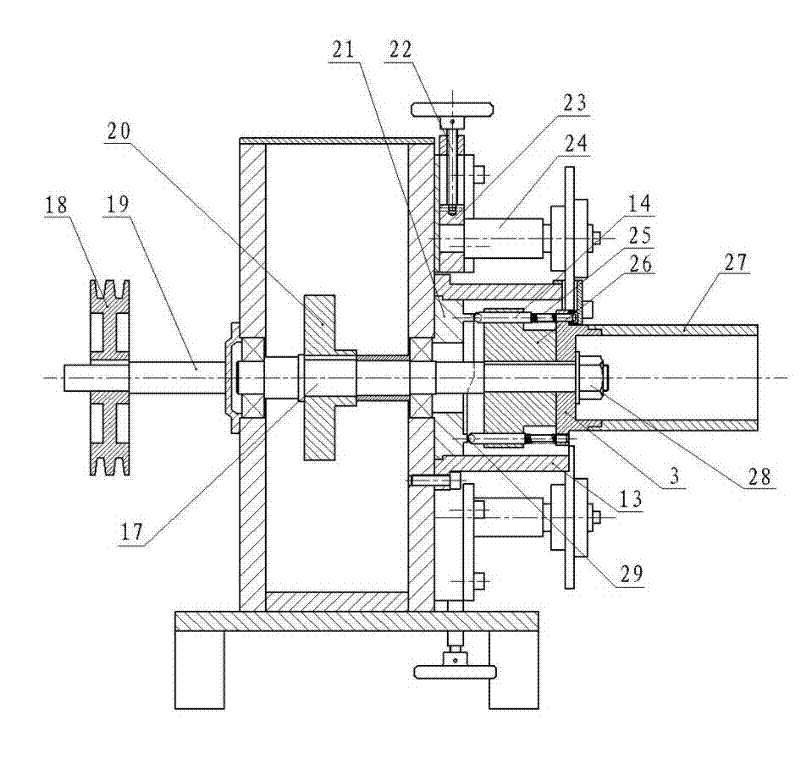

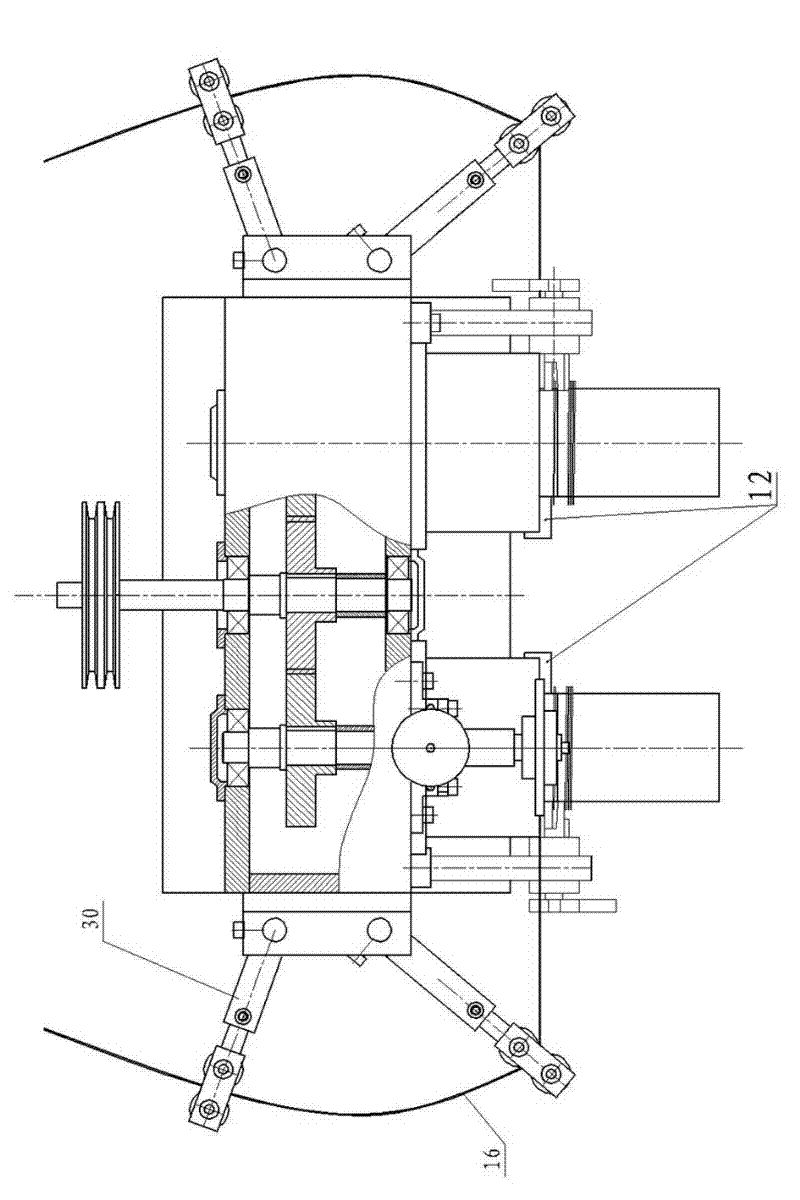

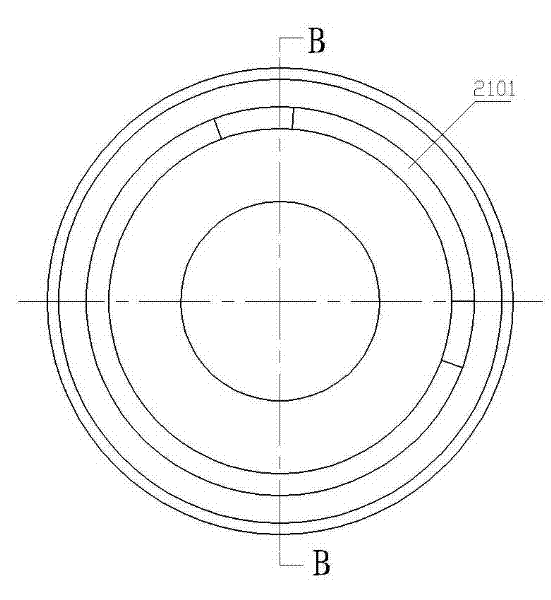

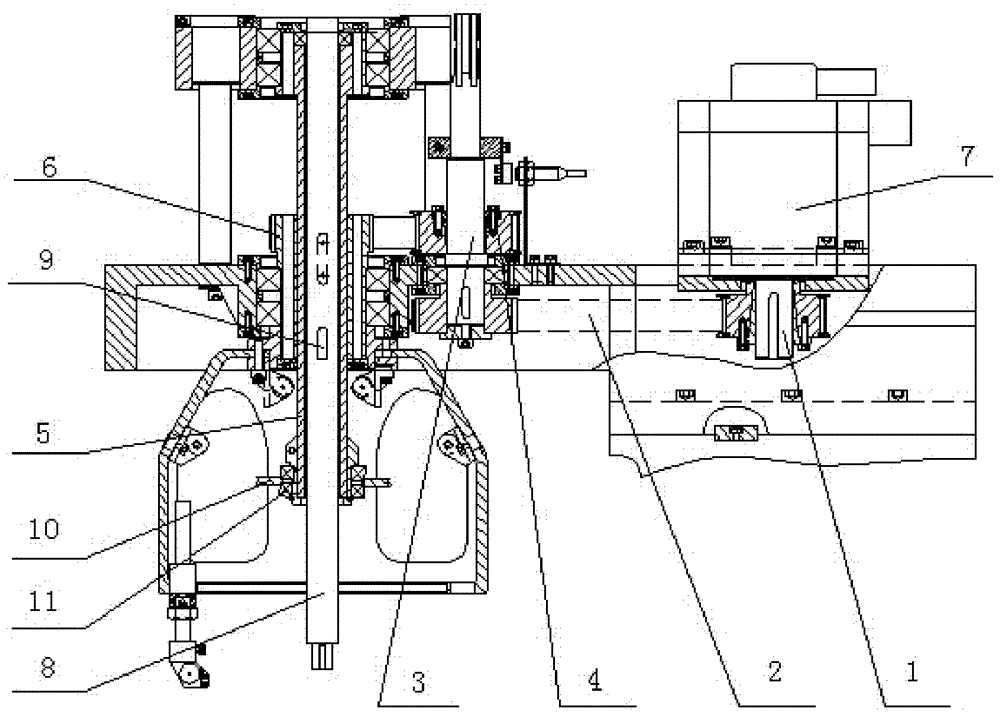

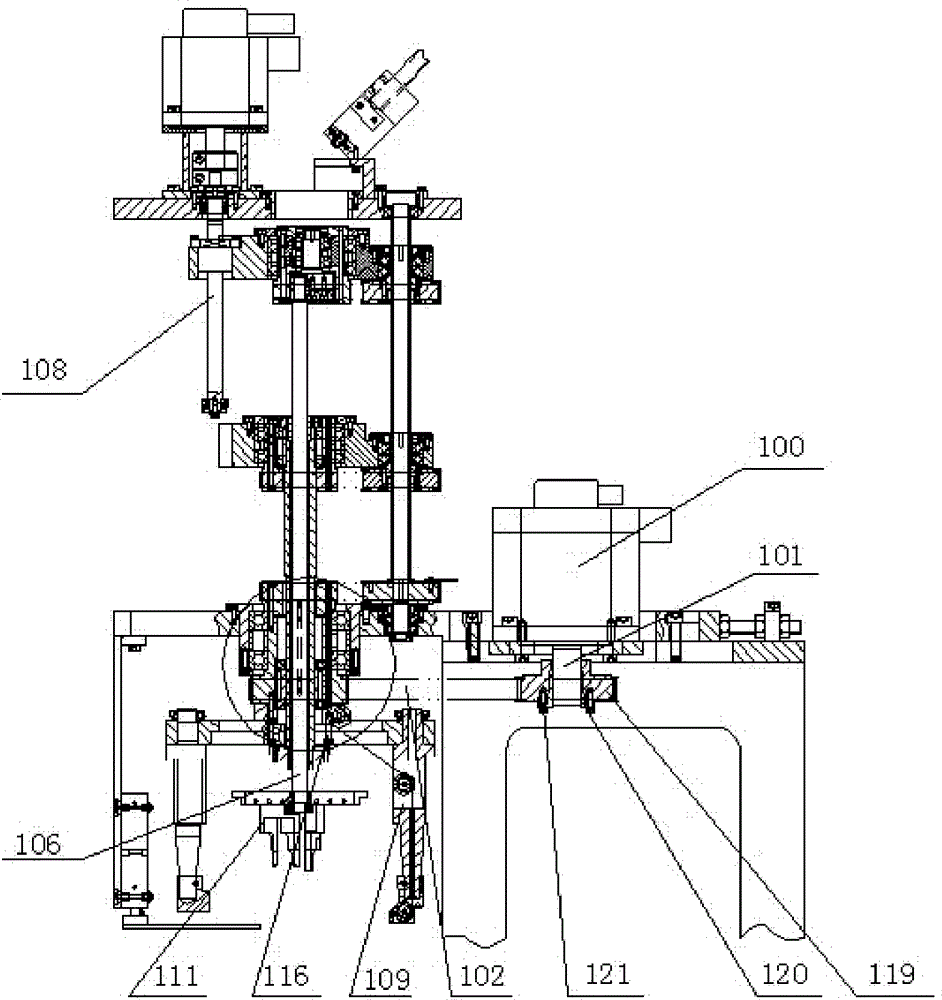

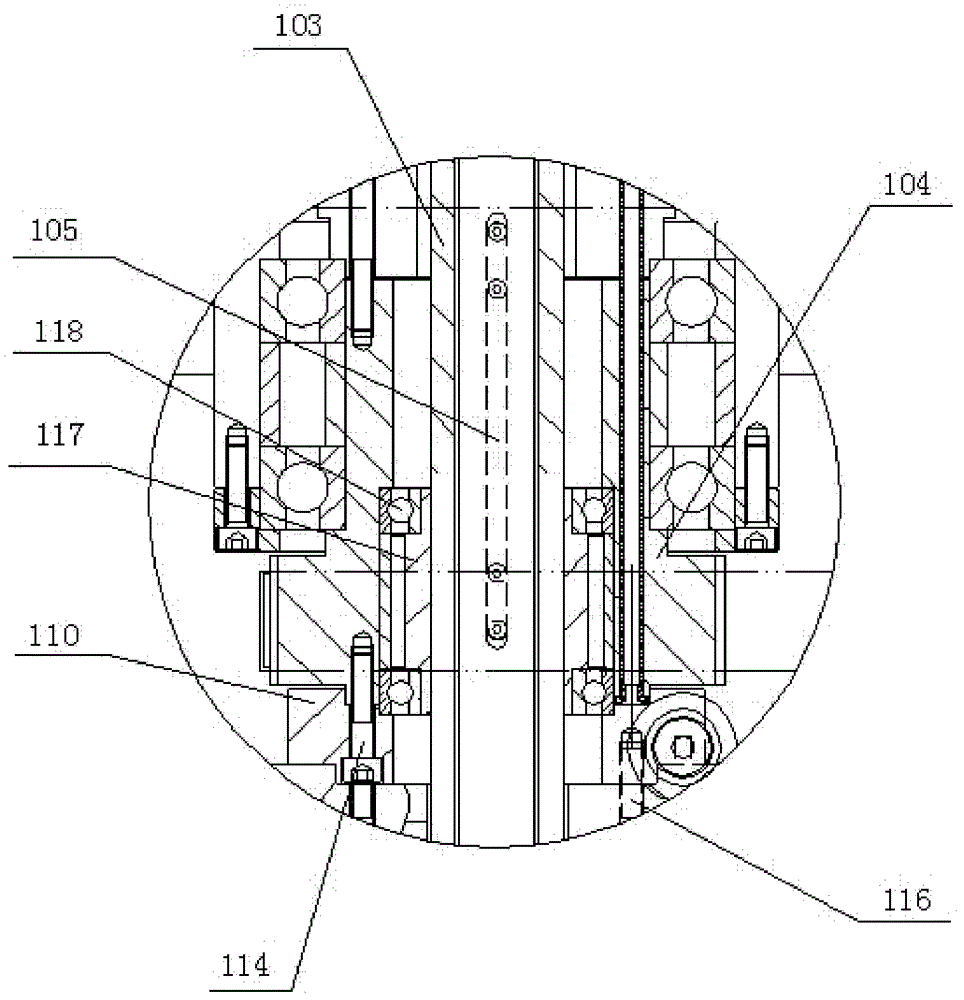

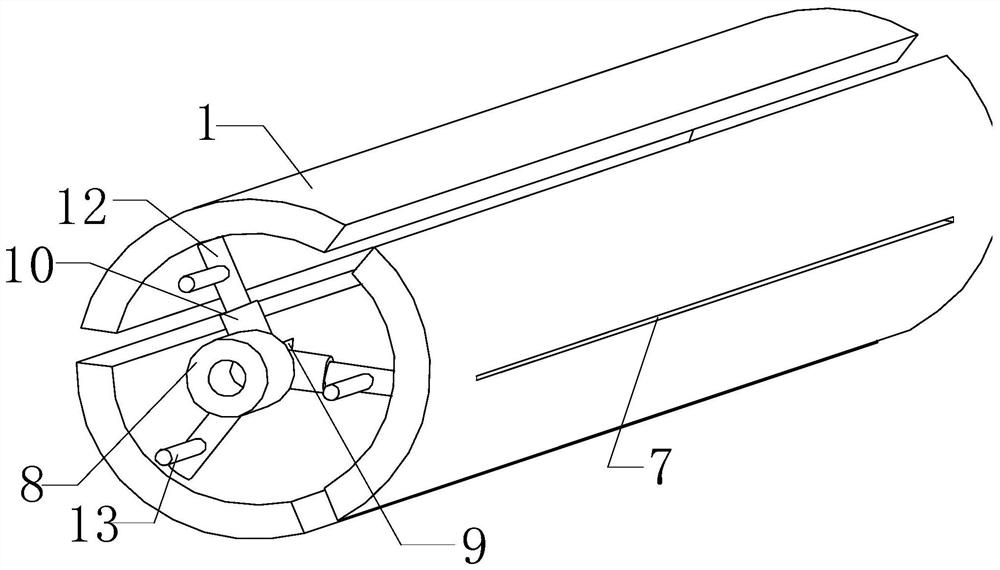

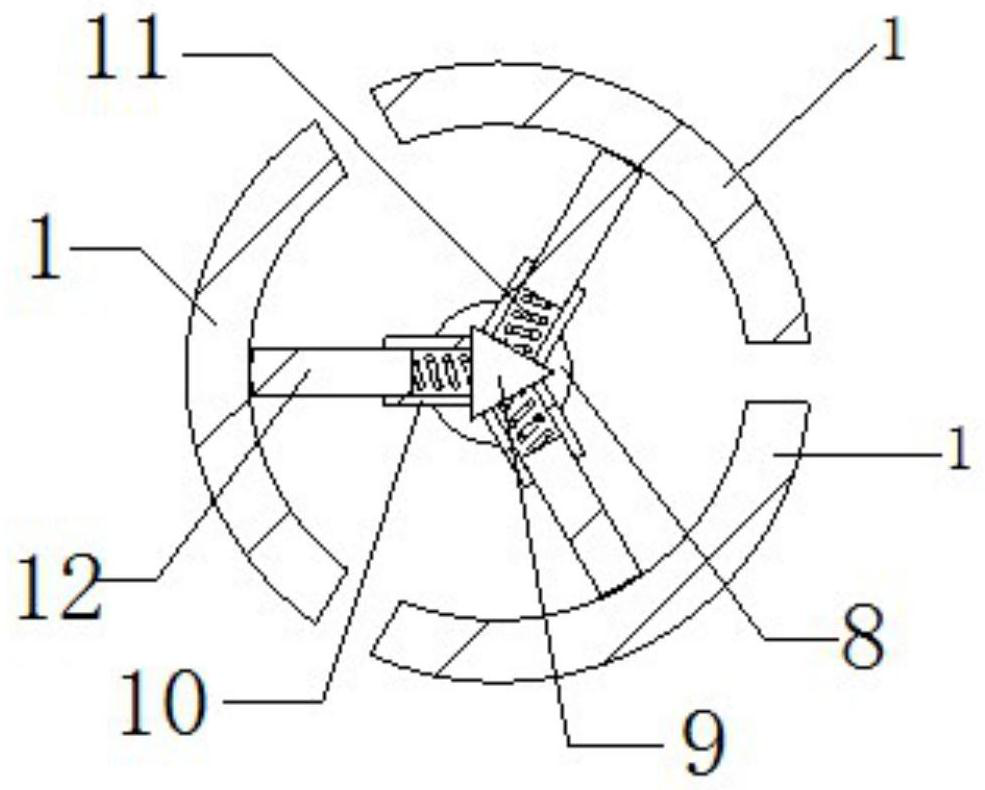

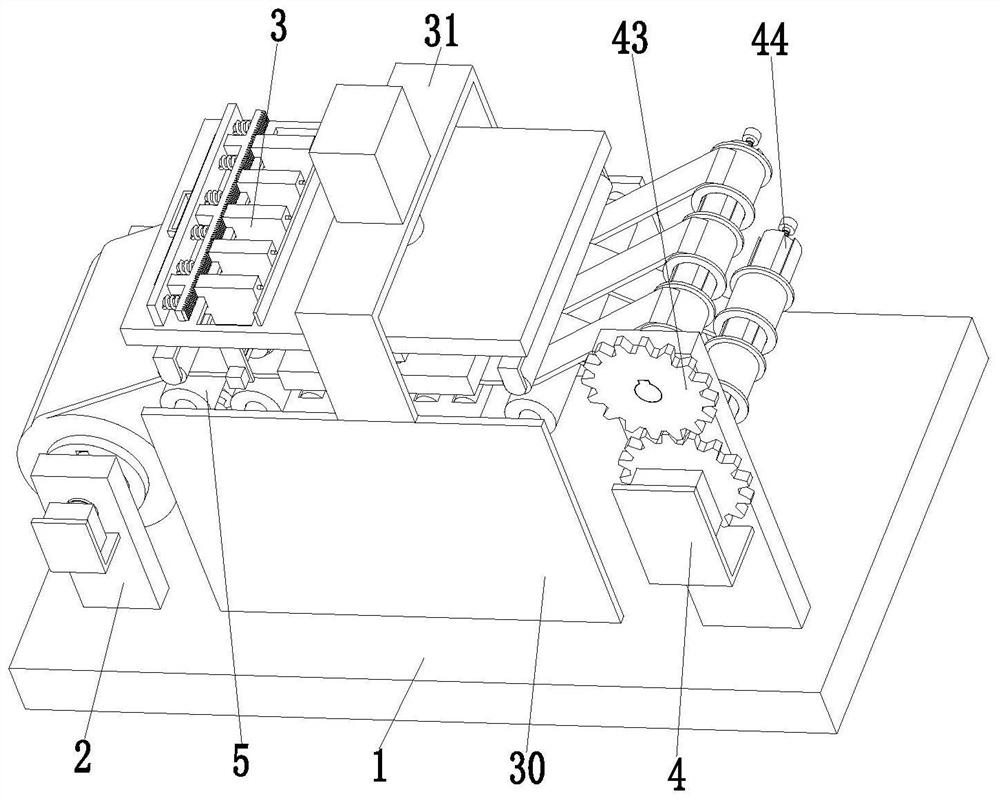

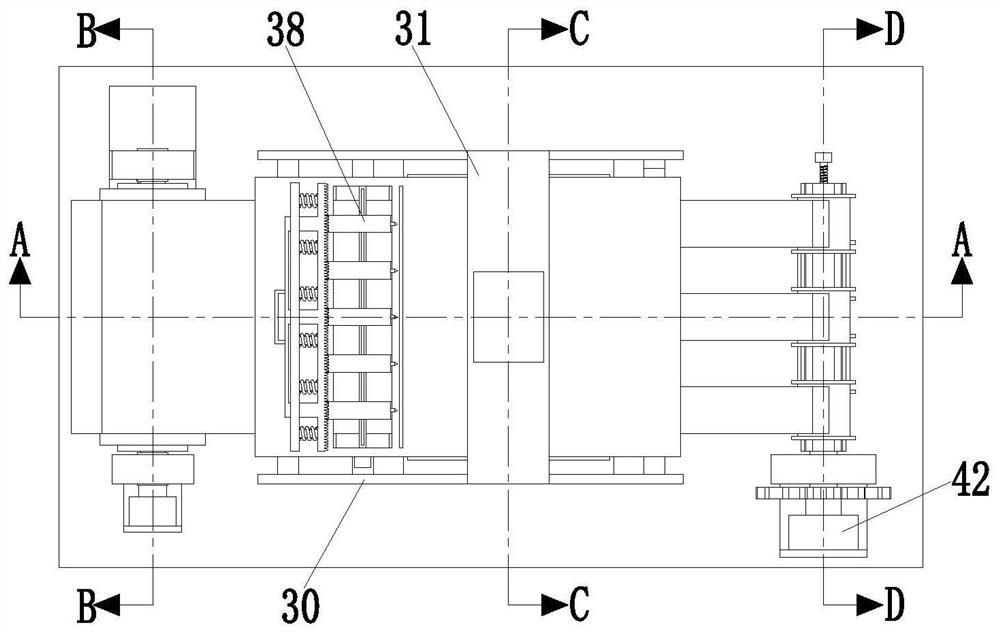

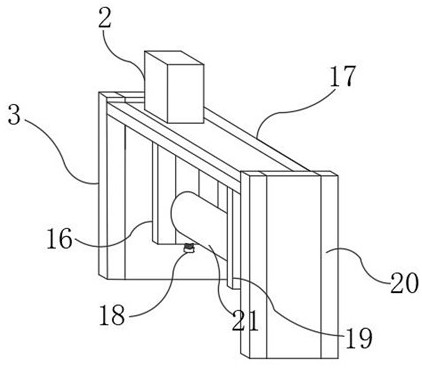

Winding machine body for automobile generator stator core

ActiveCN102299590BConvenient winding operationImprove product qualityManufacturing stator/rotor bodiesWinding machineDrive shaft

The invention discloses a winding machine body for an automobile generator stator core. The machine body comprises a box body, wherein the two sides of the front surface of the box body are respectively provided with a group of pressing wheels and winding wheels; and the parts, adjacent to the winding wheels, of the front surface of the box body, are respectively provided with a shearing device. The machine body provided by the invention is characterized in that a transmission shaft and two winding wheel shafts are arranged in the box body, the two winding wheel shafts are respectively connected with the transmission shaft, and the winding wheels are respectively fixed at the front ends of the winding wheel shafts; top wheels are sleeved on the winding wheel shafts, winding pin wheels arefixed on the winding wheel shafts, winding pins are uniformly distributed on the winding pin wheels in a penetrating manner, and the center distance of two adjacent winding pins is equal to that of two or more tooth sockets of an iron core bar stock; and through holes are uniformly distributed on the winding wheels, the outer ends of the top wheels are provided with annular bosses, and the rear ends of the winding pins are pressed on the annular bosses through springs sleeved at the front parts of the winding pins. The machine body provided by the invention has the advantages that even through the outer side of the iron core bar stock is not provided with an arc-shaped groove, or the arc-shaped groove is shallower, or the iron core bar stock is thinner, continuous batch winding can be carried out, therefore, the machine body is suitable for winding various iron core bar stocks; and the winding wheels have no mutual noninterference, the operation is stable and the product quality is good.

Owner:锦州新万得汽车部件有限公司

Auto generator stator core winding body

ActiveCN102299590AConvenient winding operationImprove product qualityManufacturing stator/rotor bodiesWinding machineDrive shaft

The invention discloses a winding machine body for an automobile generator stator core. The machine body comprises a box body, wherein the two sides of the front surface of the box body are respectively provided with a group of pressing wheels and winding wheels; and the parts, adjacent to the winding wheels, of the front surface of the box body, are respectively provided with a shearing device. The machine body provided by the invention is characterized in that a transmission shaft and two winding wheel shafts are arranged in the box body, the two winding wheel shafts are respectively connected with the transmission shaft, and the winding wheels are respectively fixed at the front ends of the winding wheel shafts; top wheels are sleeved on the winding wheel shafts, winding pin wheels arefixed on the winding wheel shafts, winding pins are uniformly distributed on the winding pin wheels in a penetrating manner, and the center distance of two adjacent winding pins is equal to that of two or more tooth sockets of an iron core bar stock; and through holes are uniformly distributed on the winding wheels, the outer ends of the top wheels are provided with annular bosses, and the rear ends of the winding pins are pressed on the annular bosses through springs sleeved at the front parts of the winding pins. The machine body provided by the invention has the advantages that even through the outer side of the iron core bar stock is not provided with an arc-shaped groove, or the arc-shaped groove is shallower, or the iron core bar stock is thinner, continuous batch winding can be carried out, therefore, the machine body is suitable for winding various iron core bar stocks; and the winding wheels have no mutual noninterference, the operation is stable and the product quality is good.

Owner:锦州新万得汽车部件有限公司

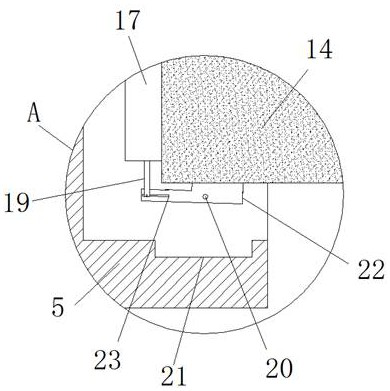

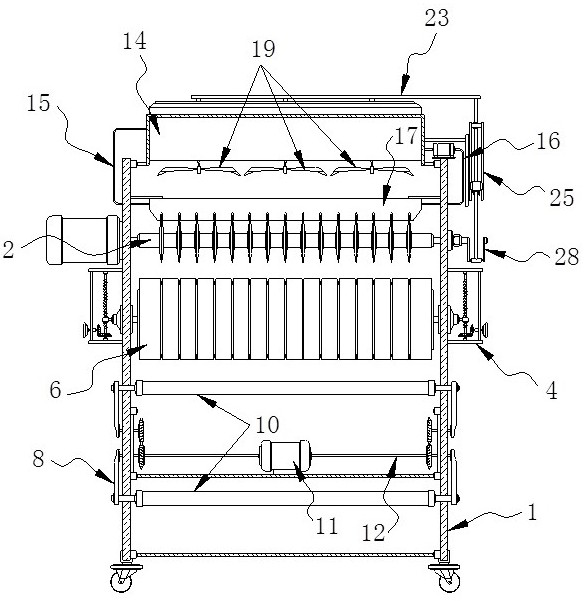

Environment-friendly cleaning machine for lining cloth processing

PendingCN112553801ARealize automatic cleaning operationRealize windingLiquid/gas/vapor removalTextile treatment by spraying/projectingProcess engineeringIndustrial engineering

The invention relates to a cleaning machine, in particular to an environment-friendly cleaning machine for lining cloth processing. The environment-friendly cleaning machine for lining cloth processing is capable of achieving automatic cleaning, convenient to wipe and capable of achieving automatic drying. The environment-friendly cleaning machine for lining cloth processing provided by the invention comprises bottom plates arranged on two sides of the bottoms of two first supports correspondingly; a winding mechanism arranged between the two first supports; a spraying mechanism arranged between the two first supports; and a driving mechanism arranged on the first support on one side; wherein the spraying mechanism is matched with the winding mechanism through the driving mechanism. By fixing lining cloth on the winding mechanism through a worker, automatic cleaning operation is achieved through cooperation of the driving mechanism and the spraying mechanism.

Owner:赖德政

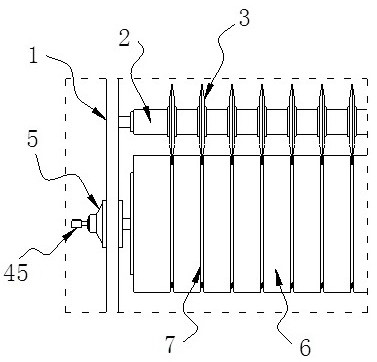

Method for manufacturing motor stator

InactiveCN1612446AImprove efficiencyConvenient winding operationManufacturing stator/rotor bodiesEngineeringConductor Coil

In the disclosed method, magnetic yoke and teeth are formed dividually, and they can be inserted into connection structure one another. Winding is enwound on reel located on outside of each tooth. Then, reel with winding being enwound is inserted into tooth respectively. Finally, teeth are connected to magnetic yoke so as to produce stator completely. Advantages are: pin in use for enwinding winding is not intervened by circumference; windings can be enwound on reel as much as possible; efficiency of motor is raised and winding operation becomes handy.

Owner:LG ELECTRONICS (TIANJIN) APPLIANCES CO LTD

The transmission structure of the winding spindle on the winding machine

Owner:NIDE MECHANICAL EQUIP

Drawing winding machine

PendingCN112875434AEasy to separateImprove work efficiencyArticle separationWebs handlingWinding machineCrank

Owner:SHAANXI UNIV OF SCI & TECH +1

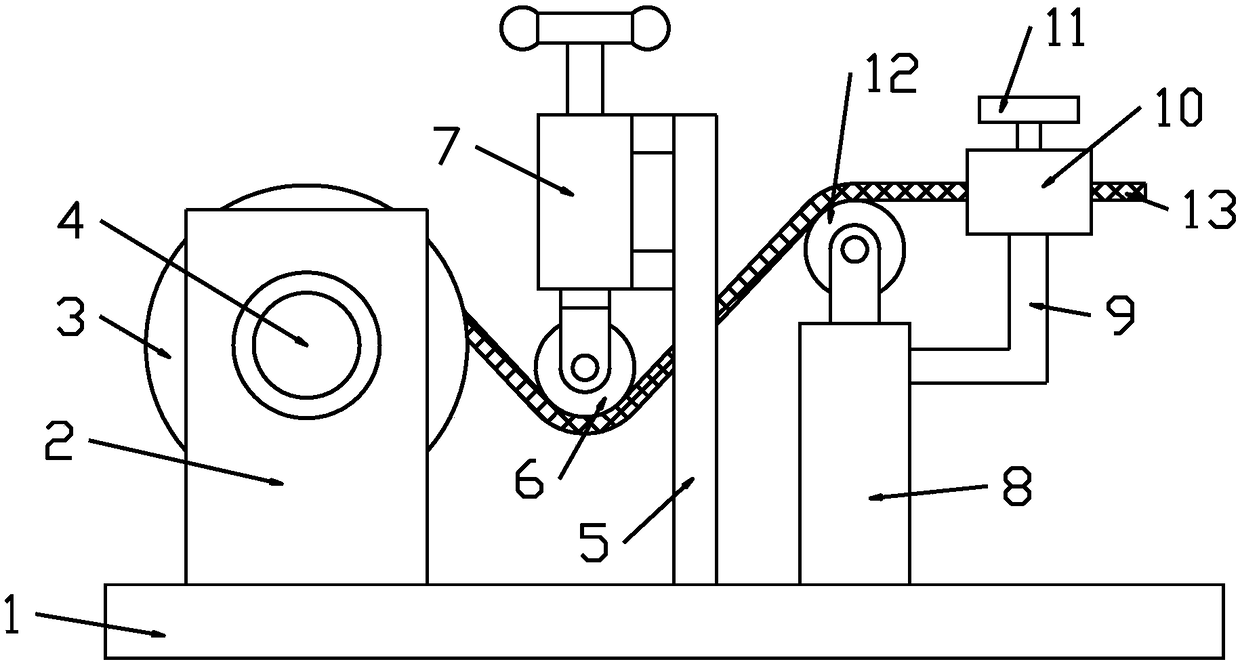

Traction winding device for enameled wire

InactiveCN108529321AEasy to unwindConvenient winding operationFilament handlingButt jointDrive shaft

The invention discloses a traction winding device for an enameled wire. The traction winding device comprises a pair of guide pipes; a butt joint pipe is arranged between one ends of the guide pipes;an inserting pipe is arranged between the other ends of the guide pipes; a traction mechanism is arranged at the front part of one guide pipe; a stepping motor is arranged at the rear part of the inserting pipe; a driving shaft is arranged at the upper part of the stepping motor; a winding wheel sleeves the outer peripheral surface of the driving shaft; the traction mechanism comprises a tractionpipe; one end of the traction pipe is arranged in the corresponding guide pipe in a sleeved mode; a movable plate is arranged at the other end of the traction pipe; a lock base is arranged at the endpart of the other end of the traction pipe; the middle part of the movable plate is fixed to the lock seat through a fixing rod; convex parts are arranged at the two ends of the movable plate; secondinstalling shafts are arranged on the convex parts; and traction wheels sleeve the outer peripheral surfaces of the second installing shafts. The traction winding device has the advantages that winding control over the enameled wire can be conveniently carried out through the winding wheel; and the stepping motor can control the winding wheel to rotate through the driving shaft, and through the winding wheel, the winding processing efficiency of the enameled wire can be greatly improved.

Owner:彭翠芳

A kind of preparation technology of packaging bag bopp heat sealing film

ActiveCN113844943BImprove efficiencyQuality improvementArticle deliveryWebs handlingMechanical engineeringMaterials science

The invention relates to a preparation process of a BOPP heat-sealing film for packaging bags, which mainly includes the following steps: raw material processing, extrusion operation, cooling corona, winding and slitting and other processes, and the used BOPP heat-sealing film slitting equipment. It includes an operating table, a roll feeding mechanism, a cutting mechanism and a rewinding mechanism. The left end of the operating table is provided with a roll feeding mechanism, a cutting mechanism is installed in the middle of the operating table, and a winding mechanism is installed on the right end of the operating table. The following problems exist in the slitting of BOPP heat-sealing film for packaging bags. First, the existing BOPP heat-sealing film for packaging bags needs to adjust the distance between the knives when slitting, but the traditional slitting mechanism is an integrated knife. It is more troublesome to replace the knives with different spacings, which reduces the slitting efficiency and quality of the BOPP heat-sealing film for packaging bags; 2. After the BOPP heat-sealing film for packaging bags is slit, it cannot be stably wound. It affects the winding efficiency and quality of BOPP heat-sealing film for packaging bags.

Owner:TIANJIN HUAHENG PACKAGING MATERIALS +1

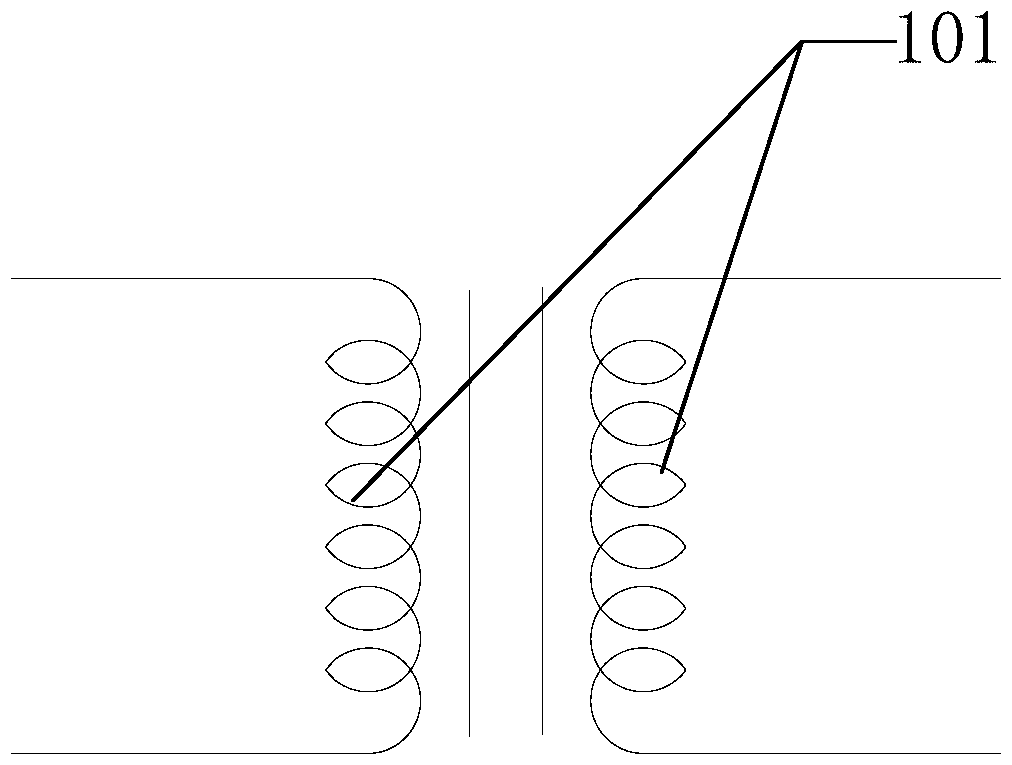

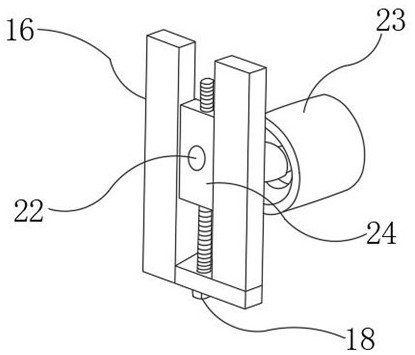

Switching power supply, emi filter, common mode inductor and its winding method

ActiveCN105336476BWill not deformImproved EMI noise suppressionMultiple-port networksTransformersInductor windingsConductor Coil

The disclosure provides a switching power supply, an EMI filter, a common mode inductor and a winding method thereof. The common mode inductor includes a first coil winding and a second coil winding, and the winding method of the common mode inductor includes: setting two isolation barriers at different positions of a magnetic core; winding the first A coil is wound on the magnetic core, and the first coil winding is divided into two winding areas by one of the spacers; the second coil is wound on the magnetic core, and the second coil winding is wound on the magnetic core. Two winding areas are separated by another spacer therein, wherein the second coil winding is wound symmetrically with the first coil winding.

Owner:DELTA ELECTRONICS JIANGSU

An isolated non-woven fabric winding machine and its use method

ActiveCN107804733BReasonable structural designHigh degree of automationWebs handlingWinding machineEngineering

The invention discloses an isolation type non-woven fabric textile winding machine which belongs to the technical field of textile winding. A cooling fan is arranged at the top of a fixed bracket; anupper flattening roller and a lower flattening roller are arranged at the top of a first bracket in sequence from top to bottom; a tensioning roller is arranged at the top of a third bracket; the tensioning roller is connected onto the third bracket through a second connecting shaft; a second through hole is formed in the top of a side wall of a second bracket; a second fixed block is arranged atthe top of the second through hole; a second rigid spring is arranged at the bottom of the second fixed block; a third connecting shaft is provided with a tracking roller; six groups of winding rollers with the same structure are arranged below the tracking roller; the winding rollers are connected with a connecting frame through a fourth connecting shaft; a ratchet wheel mechanism which is matched with a mounting groove is arranged at the left end of a fifth connecting shaft. The winding machine disclosed by the invention is reasonable in structural design and high in automation degree; simple and convenient textile winding work can be ensured and the winding effect of the fabric is remarkable.

Owner:宁夏中恒创越新材料科技有限公司

A steering rotary led riding light

ActiveCN108945191BConvenient winding operationEasy tension adjustmentOptical signalFlexible circuitsElectrical battery

A steering rotary LED bicycle riding lamp comprises a protective frame; a stepping motor is arranged on one side of the protective frame, a rotating shaft is arranged on the upper part of the steppingmotor, rotating drums are sleeved on the outer peripheral surface of the rotating shaft, a fluorescent warning cloth is wound between the rotating drums, a flexible circuit board is arranged on the fluorescent warning cloth, and a plurality of LED lamps are arranged on the flexible circuit board; a membrane battery is arrange on that fluorescent warning cloth, the membrane battery and the flexible circuit board are connected through a cable, and the LED lamps and the flexible circuit board are electrically connected; an inner bottom position of the protective frame is provided with a liftingframe, the two sides of the lifting frame are provided with guide shafts, the outer circumferential surfaces of the guide shafts are sleeved with slide pipes, and the slide pipes are installed at thebottom of the stepping motor. The invention can conveniently tension and adjust the two sides of the fluorescent warning cloth by the rotating drums. The slide pipes realizes the horizontal movement adjustment along the guide shafts, thereby facilitating the horizontal movement adjustment of the stepping motor and playing the role in warning.

Owner:国骄胶粘新材料产业园管理有限公司

Elastic composite polyester fiber filament processing device

PendingCN113718359AEasy dischargeRaise the ratioSpinning head liquid feederArtificial thread manufacturing machinesPolyesterFiber

The invention discloses an elastic composite polyester fiber filament processing device which comprises a processing device body. A first seat body and a second supporting frame plate are installed on one side of the processing device body, a device bottom plate is installed at the bottom of the processing device body, processing grooves are formed in the inner side of the first seat body and the inner side of the second supporting frame plate, an extruder driving seat is installed on the inner sides of the processing grooves, and a screw extruder is installed at one end of the extruder driving seat. The elastic composite polyester fiber filament processing device provided by the invention is provided with a tensioning type discharging and rolling mechanism, a proportioning type feeding box mechanism and a product broken end monitoring module, so that discharging and rolling operation can be conveniently and better carried out; and a tensioning adjusting structure is arranged, so that discharging is more convenient, feeding operation can be conveniently carried out, materials can be conveniently proportioned, observation is facilitated, proportioning is more accurate, broken ends of products can be monitored conveniently, and maintenance can be conducted in time if broken ends exist.

Owner:苏州扬昇纺织科技有限公司

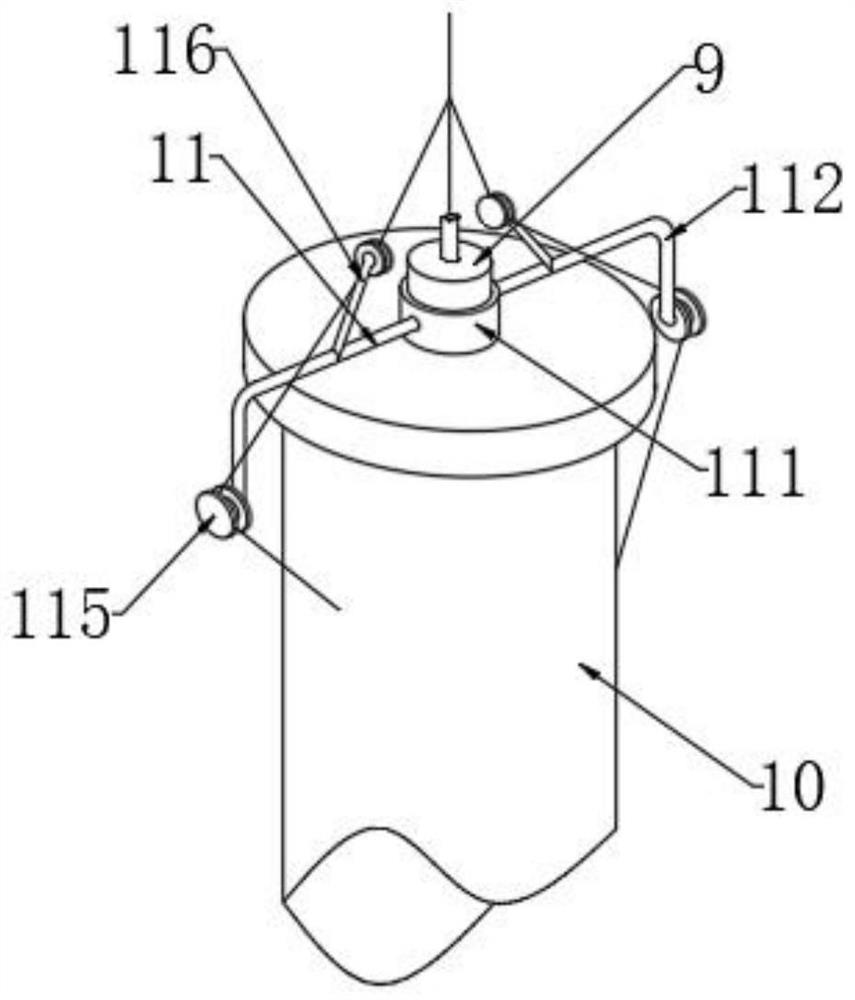

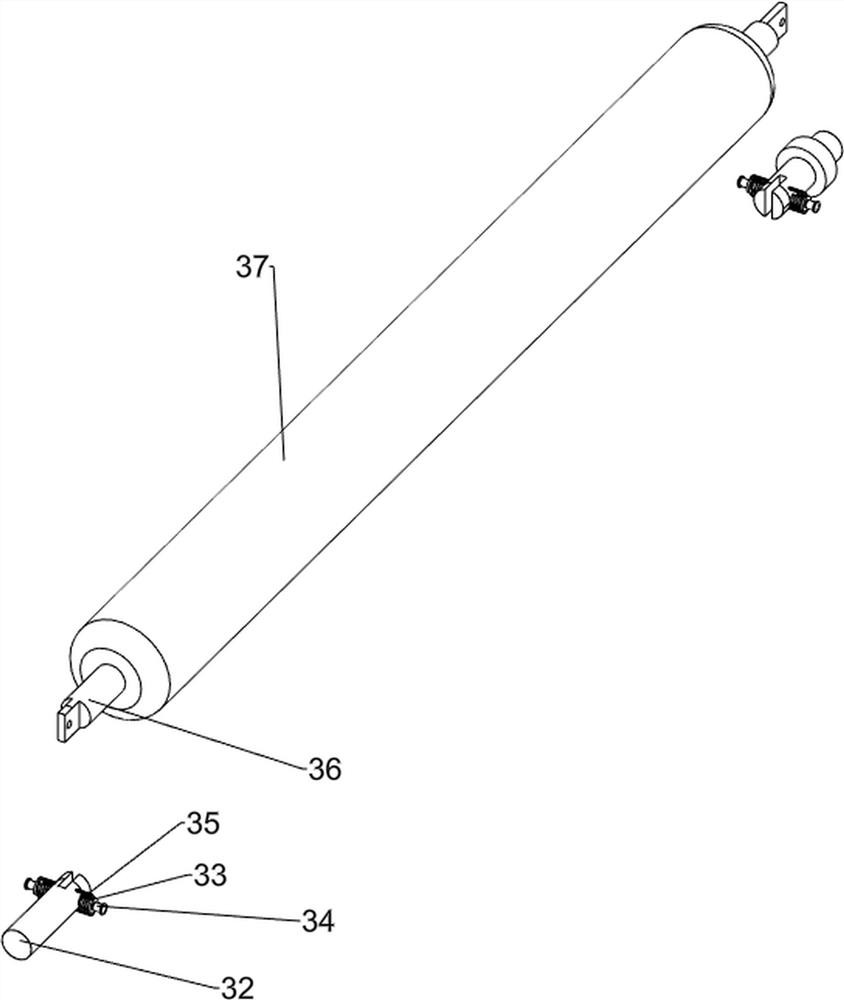

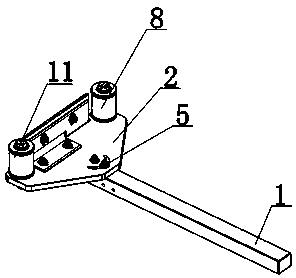

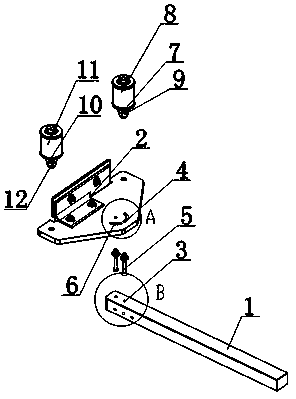

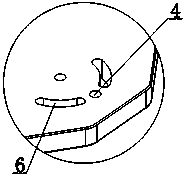

Solar thin-film cell winding device

InactiveCN108792831AConvenient winding operationFinal product manufacturePhotovoltaic energy generationMechanical engineeringSolar energy

The invention discloses a solar thin-film cell winding device which comprises a fixing pipe, wherein one end of the fixing pipe is designed to be a free end; a mounting frame is arranged at the otherend of the fixing pipe; a first fixing hole is formed in the mounting frame; a second fixing hole is formed in the end part of the fixing pipe and corresponds to the first fixing hole; fixing bolts are arranged between the end part of the fixing pipe and the mounting frame, and penetrate through the second fixing hole and the first fixing hole; a first winding roller is arranged on the mounting frame and mounted on the mounting frame through a first mounting shaft; a first lock nut is arranged between the first mounting shaft and the mounting frame; a second winding roller is arranged on the mounting frame and mounted on the mounting frame through a second mounting shaft; and a second lock nut is arranged between the second mounting shaft and the mounting frame. By the adoption of the solar thin-film cell winding device disclosed by the invention, a solar thin-film cell can be wound through the winding rollers, thereby facilitating the winding control of the solar thin-film cell.

Owner:刘宏纲

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com