Synchronous winding equipment for back-twist copper foil wires and application method thereof

A copper foil wire and twist-back technology, which is applied in the field of copper foil wire, can solve the problems of copper foil wire breakage, affecting the quality of copper foil wire winding products, and twisting copper foil wire, so as to reduce the twist and improve the winding. The effect of production quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

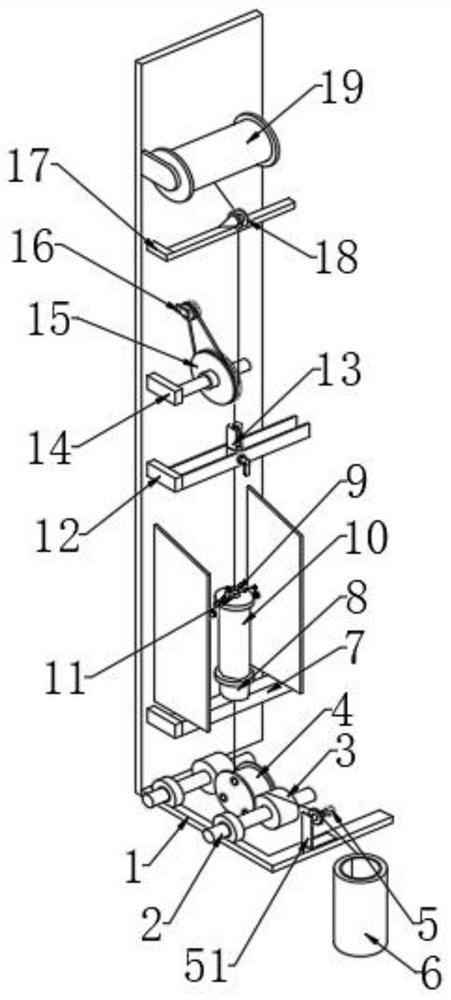

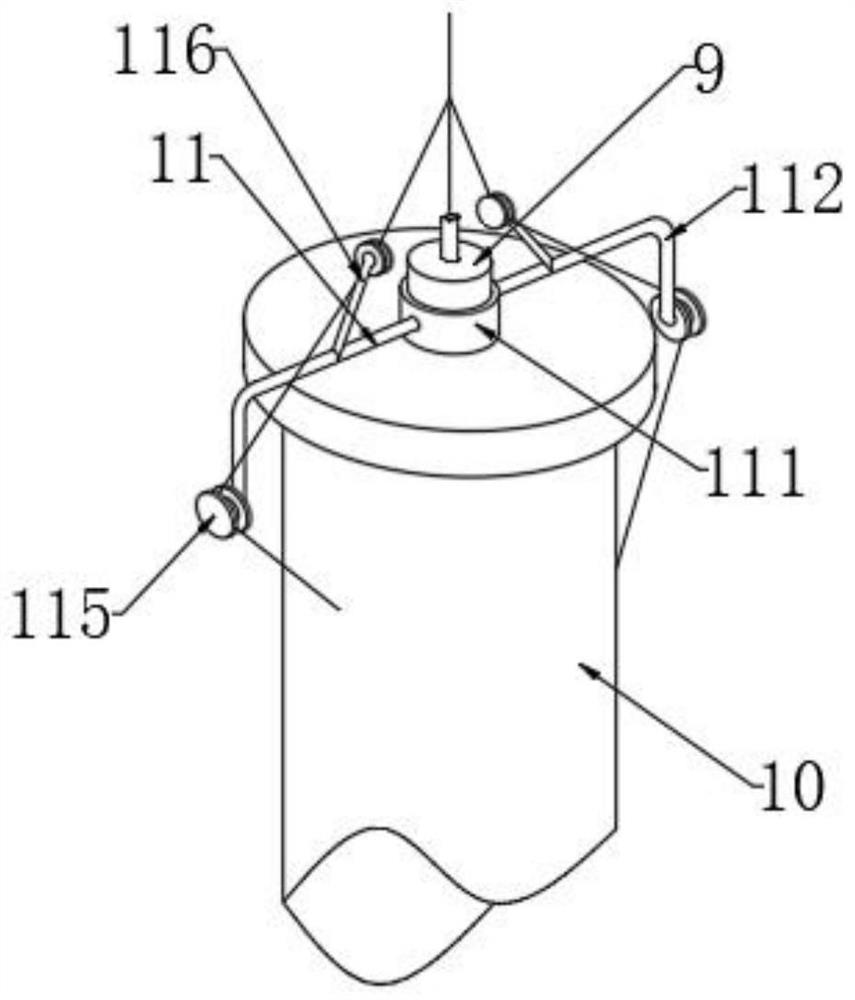

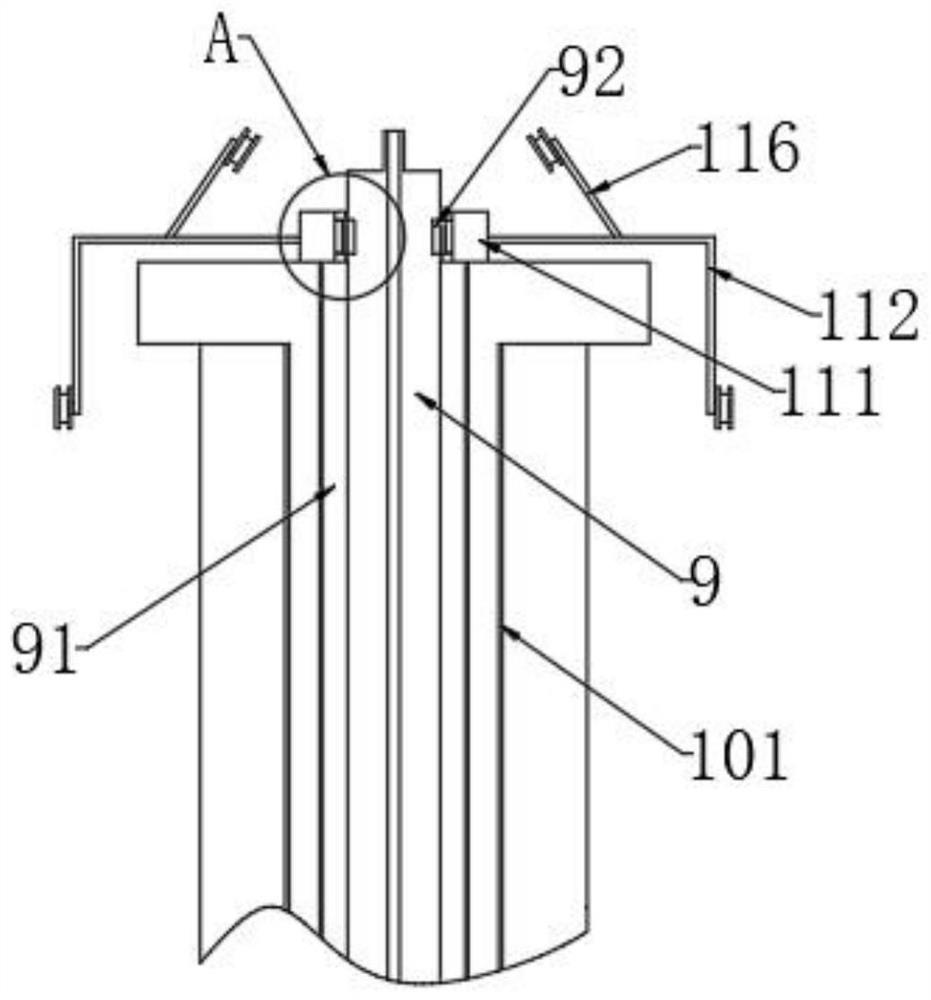

[0048] see Figure 1-3 , a synchronous winding device for untwisted copper foil wires, comprising an installation base main body 1, a pair of driving roller shafts 2 are rotatably connected to the lower end of the installation base main body 1, and engagement wheels are fixedly connected to the outer rotating shaft surfaces of the pair of driving roller shafts 2 3. The inner side of the two engaging wheels 3 is matched to clamp the crimping rotor 4, and the lower end of the installation base body 1 is fixedly connected with the cable clamp assembly 5, which is located on the outside of the engagement wheel 3, and the installation base body 1 Platinum wire 6 is provided on the outer side of the body, and the platinum wire 6 is in contact with the clamp assembly 5. The platinum wire 6 surrounds the outer circumferential surface of the crimping rotor 4, and the front of the installation base main body 1 is fixedly connected with the first connecting base. 7. The upper end of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com