Environment-friendly cleaning machine for lining cloth processing

A cleaning machine and environmental protection technology, applied in the field of cleaning machines, can solve the problems of unclean wiping and labor consumption, and achieve the effect of efficient cleaning and quality assurance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

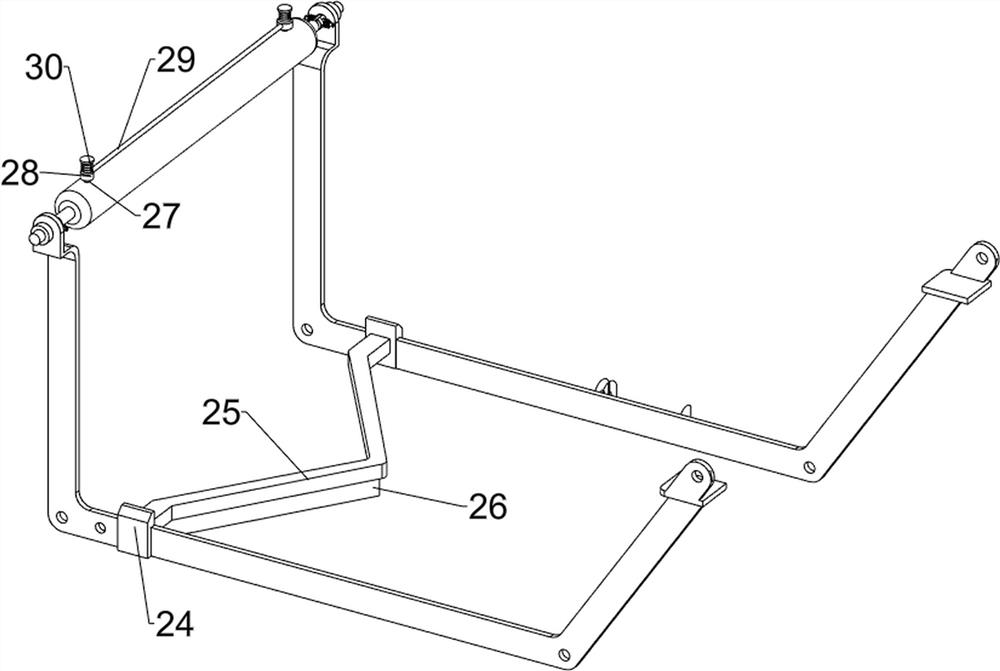

[0027] like figure 1 As shown, an environmentally friendly cleaning machine for interlining processing includes a bottom plate 1, a first bracket 2, a winding mechanism 3, a spraying mechanism 4 and a driving mechanism 5, and the bottom sides of the two first brackets 2 are provided with a bottom plate 1, A winding mechanism 3 is provided between the two first supports 2, a spraying mechanism 4 is provided between the two first supports 2, a drive mechanism 5 is provided on the first supports 2 on the front and rear sides, and the spray mechanism 4 passes through the drive mechanism. 5 cooperates with winding mechanism 3.

[0028] When it is necessary to clean the interlining, the staff first fix the interlining on the winding mechanism 3, and then start the spraying mechanism 4, and wait for the interlining to pass through the spraying mechanism 4 to spray and clean the interlining, thereby driving the driving mechanism 5 to pass through the cleaned interlining. The winding ...

Embodiment 2

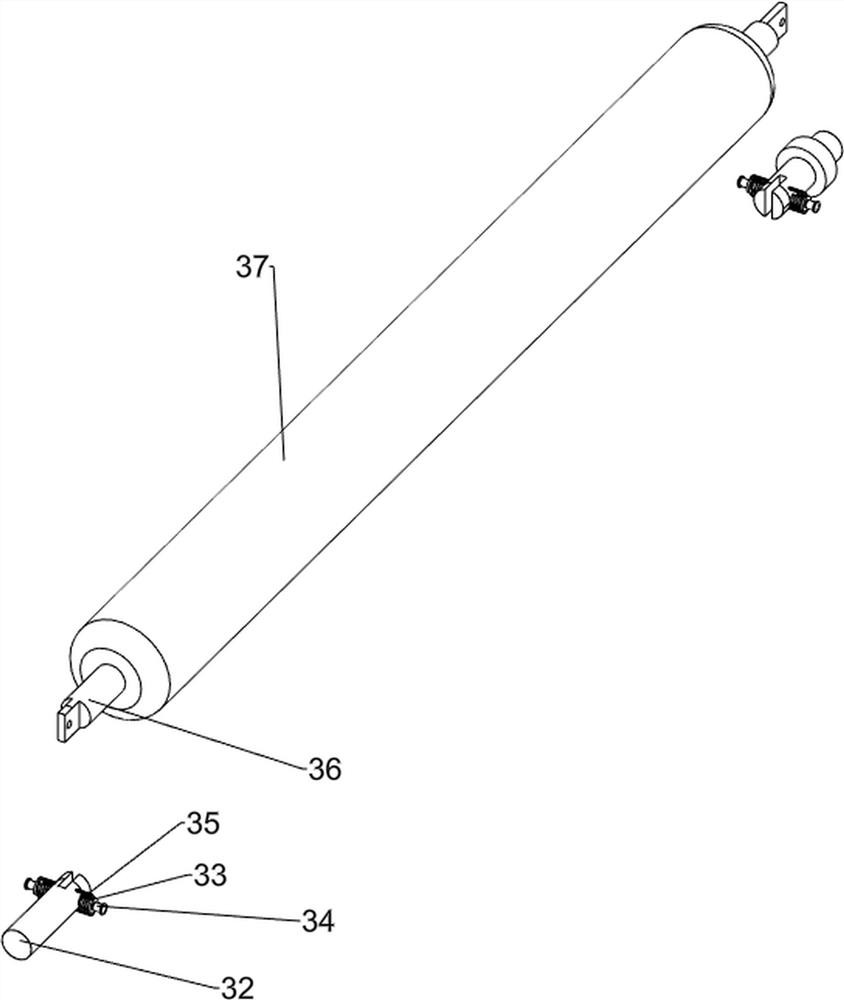

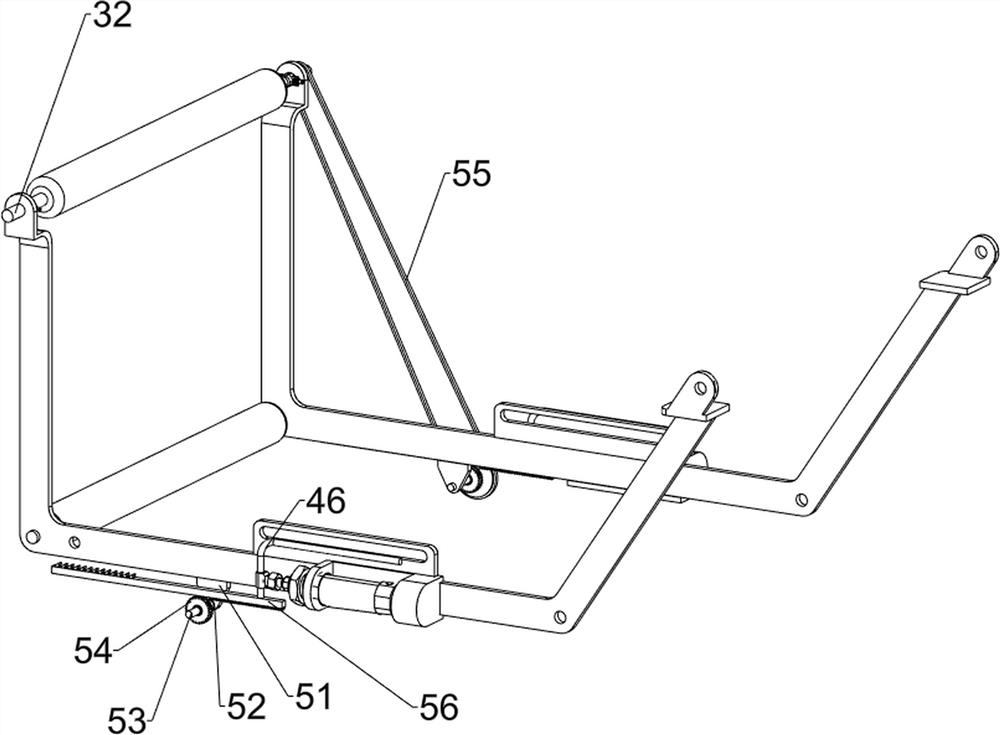

[0030] like figure 2 , image 3 ,and Figure 4 As shown, on the basis of Embodiment 1, an environmentally friendly cleaning machine for interlining processing, the winding mechanism 3 includes a guide roller 31, a first rotating shaft 32, a guide sleeve 33, a first slide bar 34, and a first elastic member 35 , the second rotating shaft 36 and the cylindrical roller 37, the guide roller 31 is rotatably arranged between the bending places of the two first supports 2, the first rotating shaft 32 is rotatably arranged at the ends of the two first supports 2, and Both sides of the opposite end of a rotating shaft 32 are symmetrically provided with guide sleeves 33 , inside the guide sleeves 33 are slidingly provided with first sliding rods 34 , and between the first rotating shaft 32 and the first sliding rods 34 are provided with first elastic members 35 , the first elastic member 35 is a tension spring, the two ends of the cylindrical roller 37 are provided with a second rotat...

Embodiment 3

[0036] like Figure 5 and Image 6 As shown, on the basis of Embodiment 2, an environmentally friendly cleaning machine for interlining processing also includes a second support 6, a dryer 7, a slide rail 8, an electrode block 9, a first slide 10, a second slide Slot plate 11, second sliding block 12, second connecting rod 13, second elastic member 14, third chute plate 15, third sliding rod 16 and pull cord 17, the side walls of the two first brackets 2 are symmetrical front and rear A second bracket 6 is provided, and two dryers 7 are arranged between the second brackets 6, and the two dryers 7 are arranged facing each other, and a slide rail 8 is arranged on the shell of the dryer 7 on the left, and inside the slide rail 8 Electrode blocks 9 are symmetrically arranged on the front and rear sides, and the electrode blocks 9 are connected to the dryer 7 through lines. Two first sliders 10 are slidably arranged in the slide rail 8, and the center of the bottom of the shell of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com