The transmission structure of the winding spindle on the winding machine

A technology of transmission structure and winding machine, applied in the field of transmission structure, can solve the problems of short service life, large operation noise, decreased operation stability, etc., and achieve the effects of reducing wear and noise, prolonging service life and stable winding operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

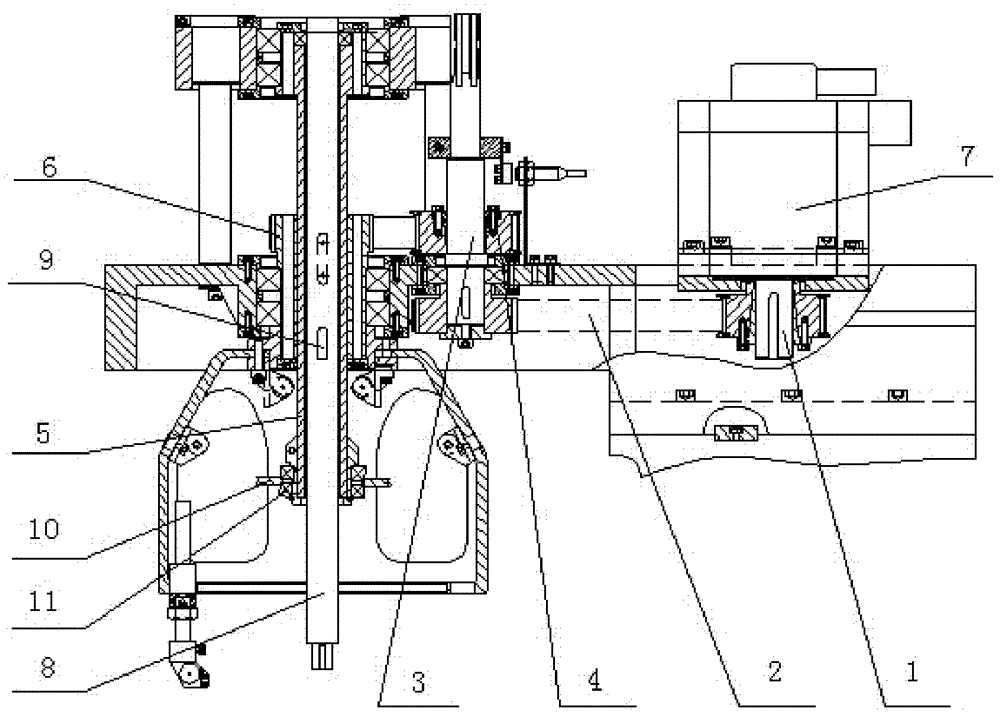

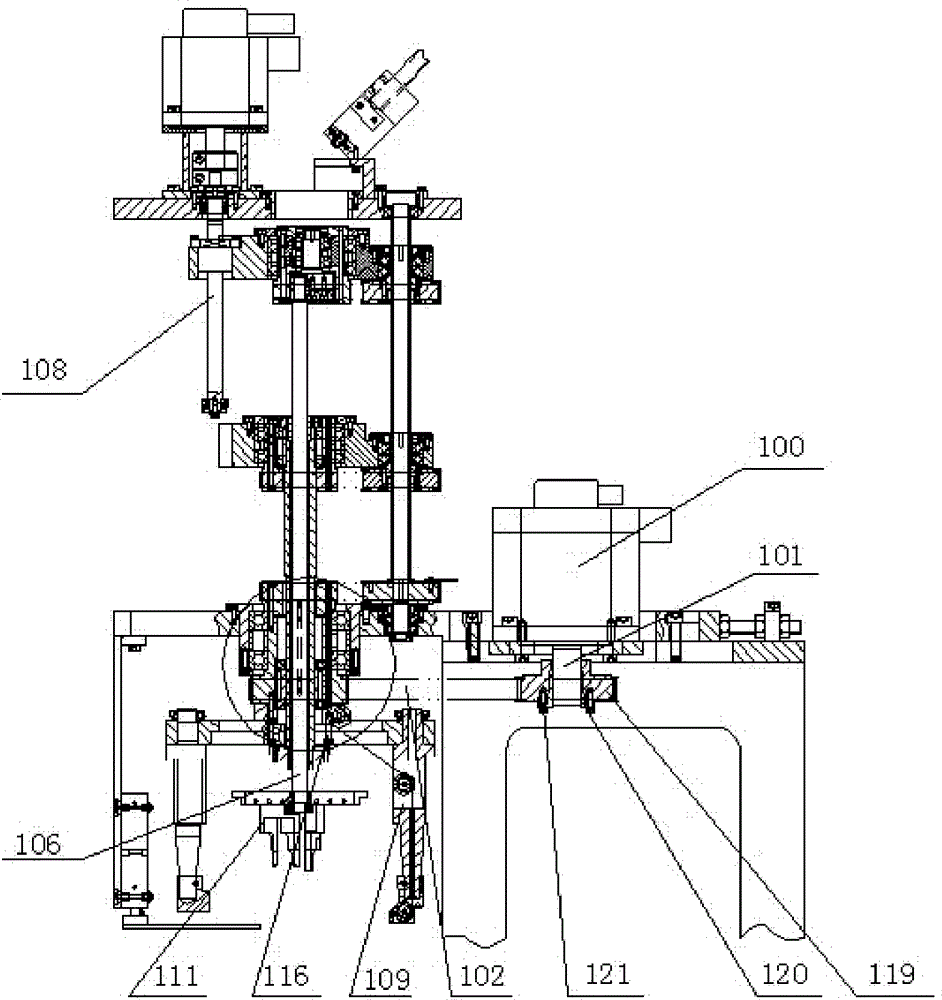

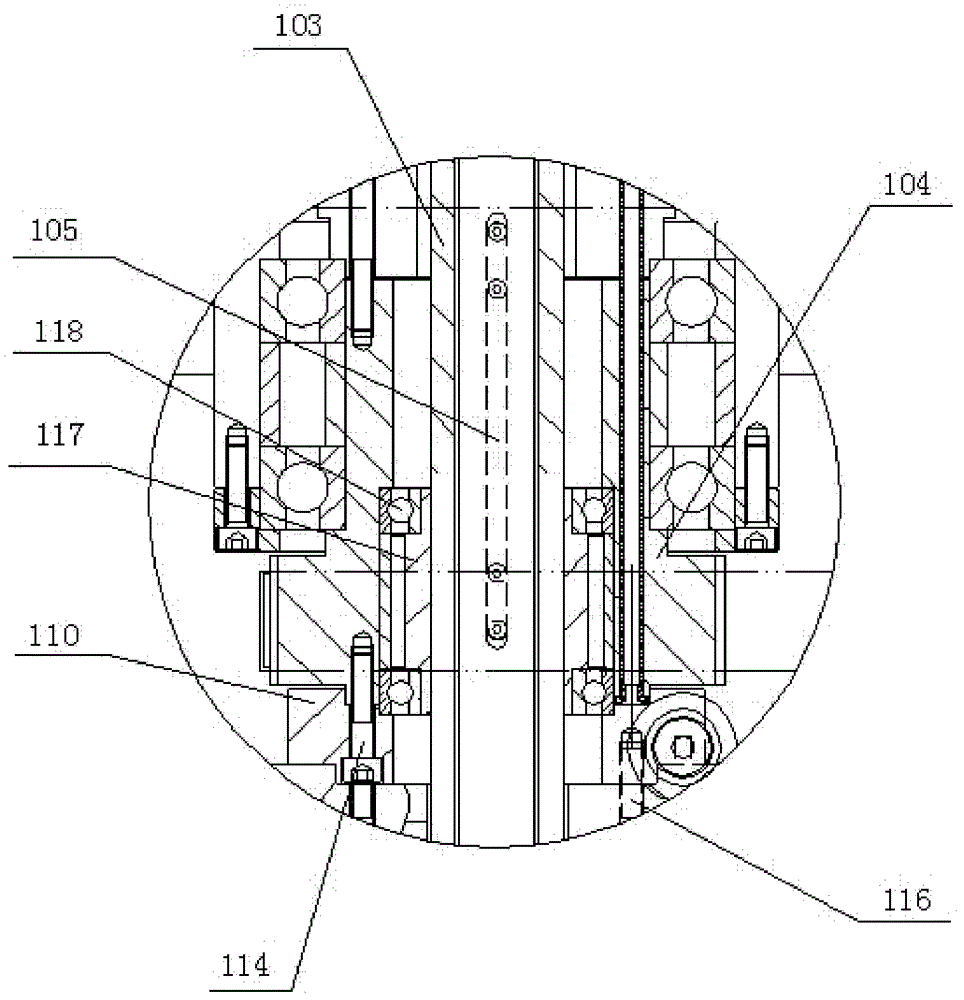

[0022] Example 1: see figure 2 , 3 As shown, a transmission structure of a winding spindle on a winding machine includes a servo motor 100, a timing belt 102 connected to the output shaft 101 of the servo motor, and the timing belt 102 is connected to a spindle synchronization wheel 104 provided on the winding spindle 103 , The winding spindle 103 is connected to the eccentric shaft 106 via a sliding key 105, the spindle synchronization wheel 104 is connected to the winding spindle 103 via a bearing assembly, and the top of the eccentric shaft 106 is fixedly installed in the head lifting mechanism 108 , The winding assembly 109 is connected to the spindle synchronization wheel 104 via the winding arm connecting seat 110, the winding mold assembly 111 is mounted on the eccentric shaft 106, and the winding arm connecting seat 110 is provided with the spindle The connection hole connected to the synchronization wheel 104 and the screw hole connected to the winding assembly 109. Th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com