An end insulation assembly of a direct-wound motor stator

A technology of end insulation and motor stator, which is applied to the shape/style/structure of electric components, windings, and winding insulation. It can solve problems such as inclined deformation of the inner wall, damage to the rotor, and enameled wires, so as to improve reliability and facilitate winding. Line work, unique design effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

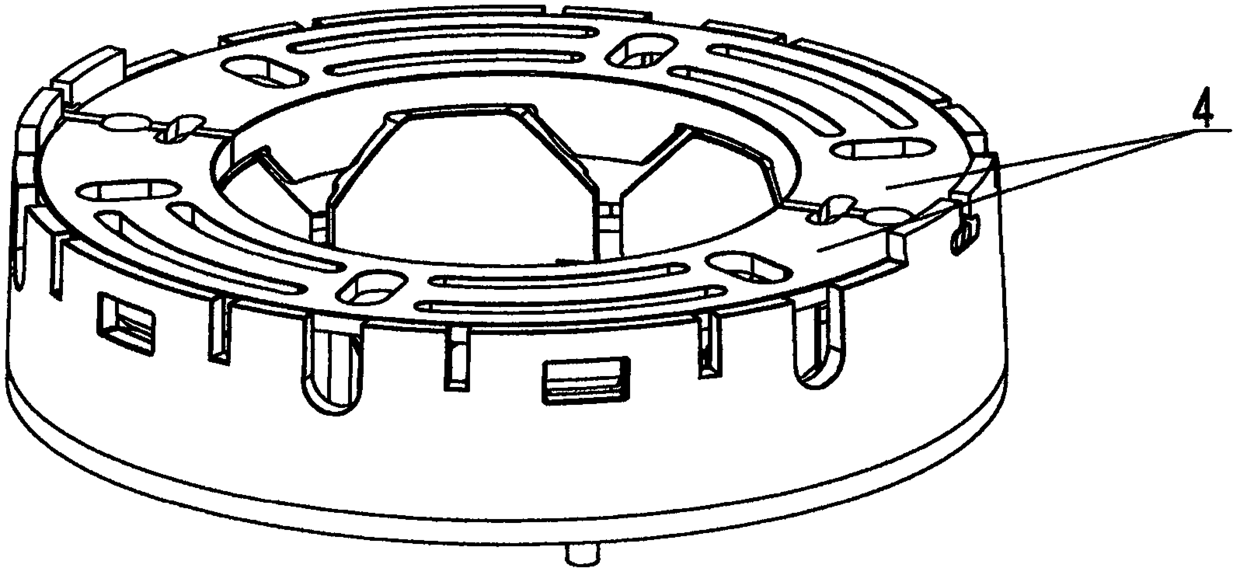

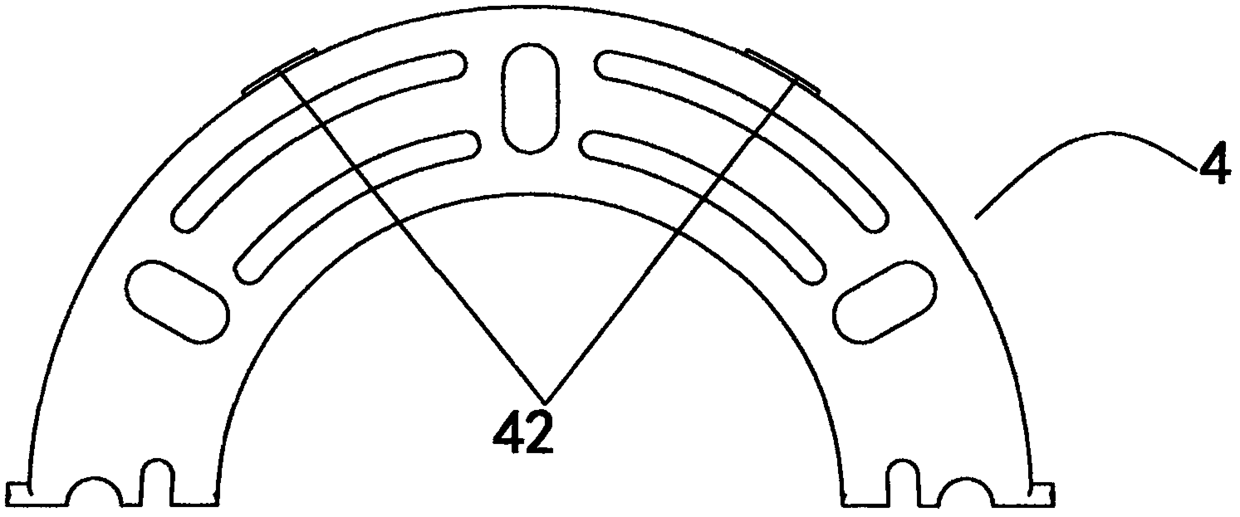

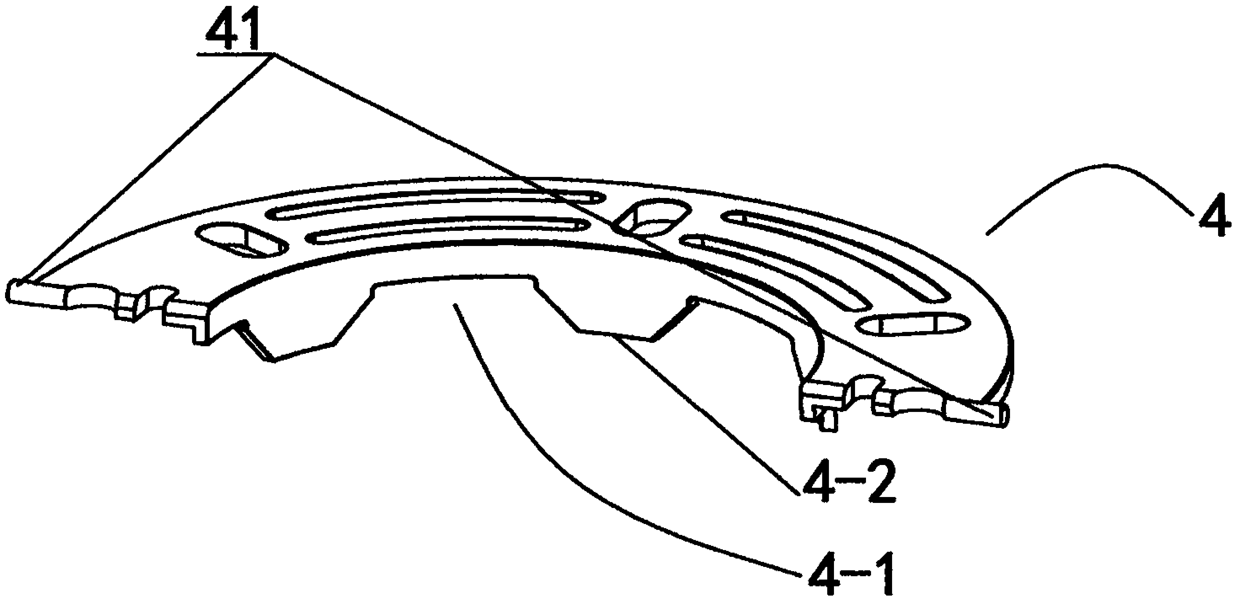

[0021] See Figure 1-7 As shown, an end insulation assembly of a straight-wound motor stator is protected by a coil insulation bracket K installed symmetrically up and down on both ends of the stator core G and a coil installed on at least one of the coil insulation brackets Composed of end caps, the coil protection end cap is composed of two semi-rings with symmetrical structures and 4 pairs. Wherein, each coil insulation support K includes an outer wall part 1 in the shape of a ring, an inner wall part 2 arranged at intervals in the circumferential direction, and a stator extending in the radial direction and connected with the inner wall part 2 and the outer wall part 1 for supporting the stator. A plurality of winding support parts 3 of the winding (known parts are not shown in the figure), there is a notch 20 between two adjacent inner wall parts 2, and the head ends 2-1 of the inner wall parts 2 are tongue-shaped, and adjacent Protrusions 21 and guiding slots 22 for ins...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com