A kind of preparation technology of packaging bag bopp heat sealing film

A preparation process and heat-sealing film technology, used in transportation and packaging, thin material processing, winding strips, etc., can solve the problem of unwinding operations, reduce packaging bag BOPP heat-sealing film cutting efficiency and quality, trouble, etc. problems, to achieve the effect of improving the efficiency and quality of winding, improving the efficiency and quality of wind shearing, and preventing sliding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

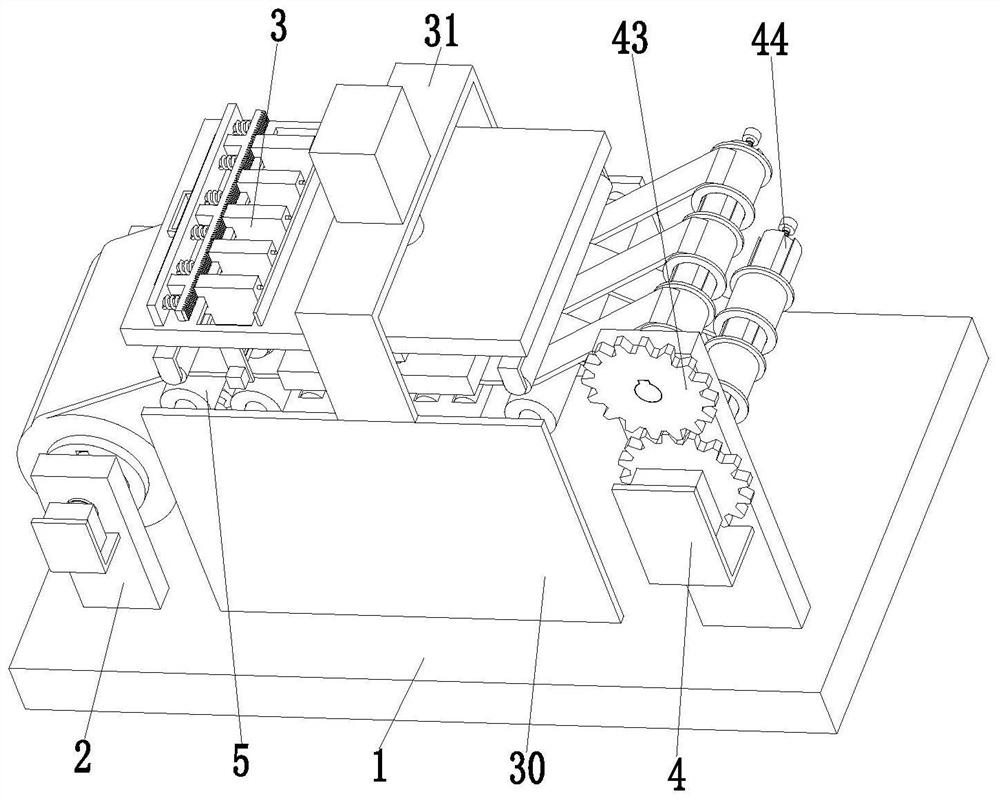

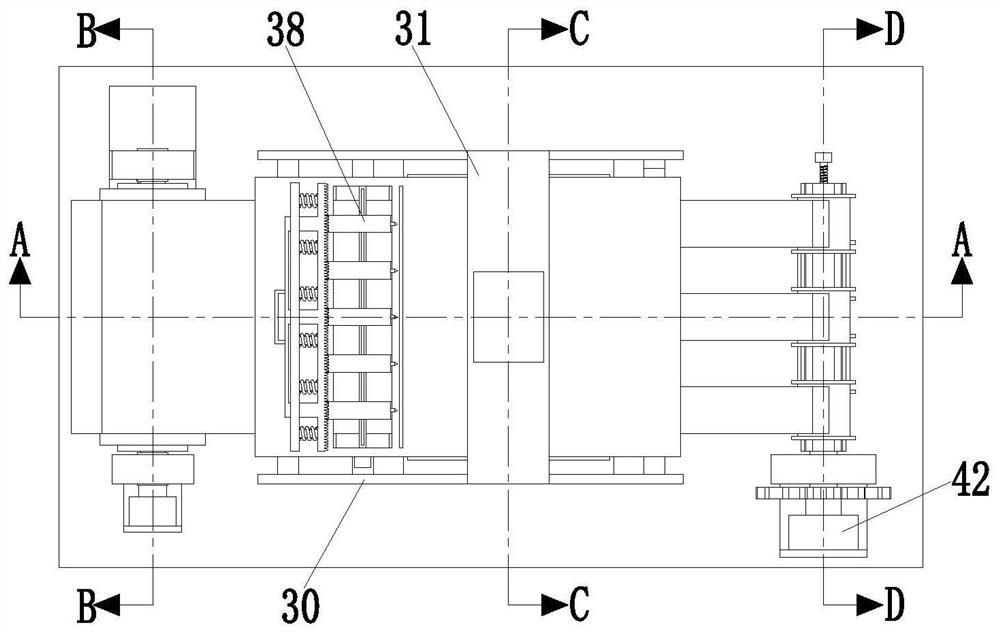

[0034] The embodiments of the present invention are described in detail below with reference to the accompanying drawings, but the present invention can be implemented in many different ways as defined and covered by the claims.

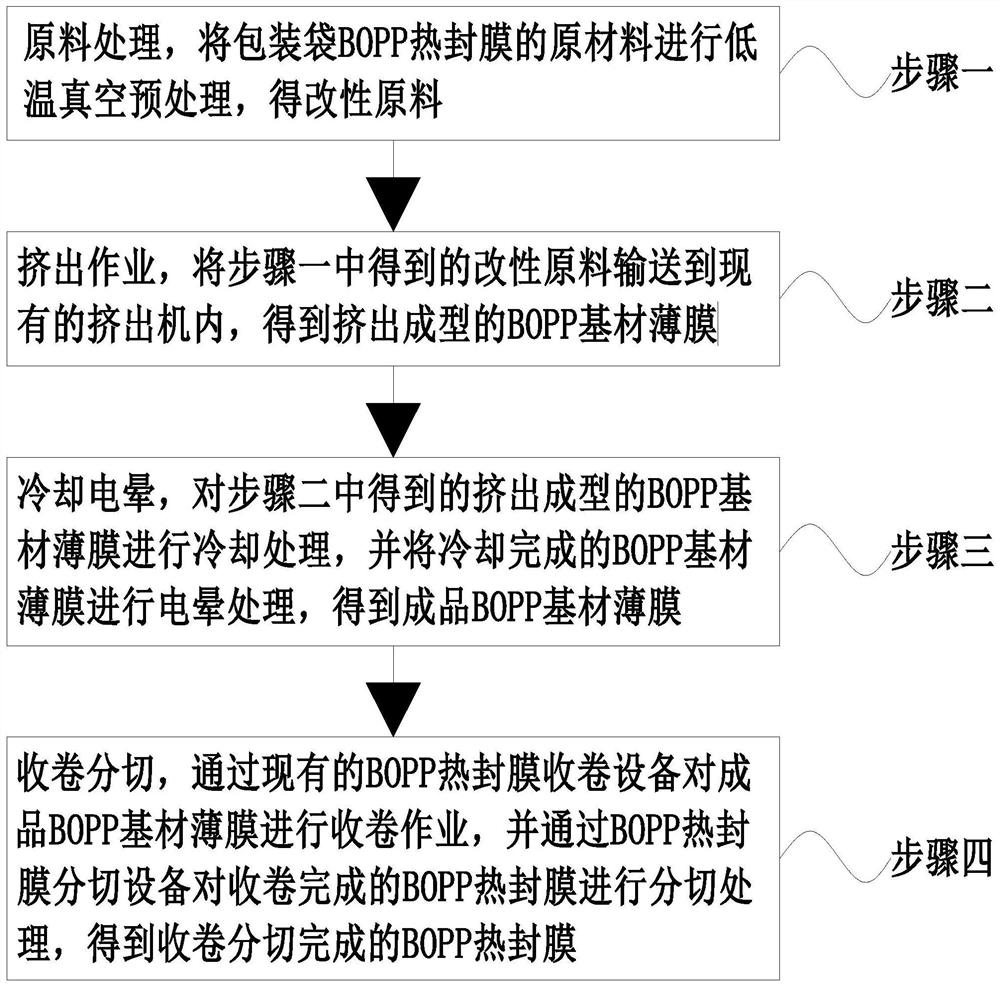

[0035] see figure 1 , a preparation process of BOPP heat-sealing film for packaging bags, mainly comprising the following steps:

[0036] Step 1, raw material treatment, carry out low temperature vacuum pretreatment on the raw material of the BOPP heat-sealing film of the packaging bag to obtain modified raw materials;

[0037] In step 2, extrusion operation, the modified raw material obtained in step 1 is transported into an existing extruder to obtain an extruded BOPP base film;

[0038] Step 3, cooling the corona, cooling the extruded BOPP base film obtained in the second step, and subjecting the cooled BOPP base film to corona treatment to obtain a finished BOPP base film;

[0039] Step 4: Rewinding and slitting, using the existing BOPP heat-se...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com