Elastic composite polyester fiber filament processing device

A processing device and composite polyester technology, applied in fiber processing, filament forming processing, feeding solution to the spinneret, etc., can solve problems such as unfavorable use, inconvenient observation, troublesome proportioning, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

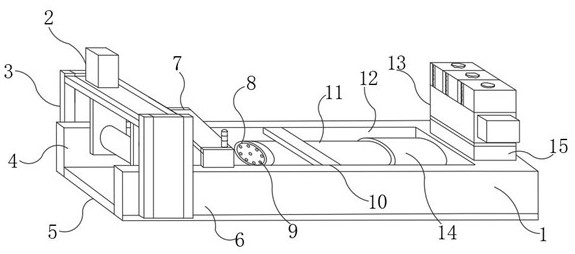

[0028] like Figure 1-3 As shown, an elastic composite polyester fiber filament processing device includes a processing device main body 1, a No. 1 seat 4 and a No. 2 seat 6 are installed on one side of the processing device main body 1, and a device is installed on the bottom of the processing device main body 1. Bottom plate 5, No. 1 base body 4 and No. 2 base body 6 are provided with a processing groove 12 inside, an extruder driving seat 14 is installed on the inside of the processing groove 12, and a screw extruder is installed on one end of the extruder driving seat 14 11. An extruder 8 is installed at one end of the screw extruder 11, and the inner side of the extruder 8 is provided with a filamentary forming port 9, and a support rod 10 is installed at the position where the upper end of the processing tank 12 contacts the screw extruder 11.

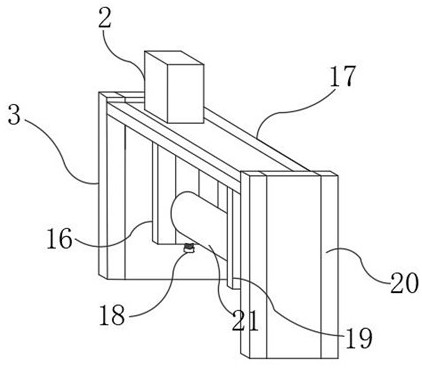

[0029] Further, a No. 1 support frame plate 3 is installed on the outside of the No. 1 seat body 4, and a No. 2 support frame p...

Embodiment 2

[0032] On the basis of Example 1, as figure 1 , 4 As shown, an elastic composite polyester fiber filament processing device includes a processing device main body 1, a No. 1 seat 4 and a No. 2 seat 6 are installed on one side of the processing device main body 1, and a device is installed on the bottom of the processing device main body 1. Bottom plate 5, No. 1 base body 4 and No. 2 base body 6 are provided with a processing groove 12 inside, an extruder driving seat 14 is installed on the inside of the processing groove 12, and a screw extruder is installed on one end of the extruder driving seat 14 11. An extruder 8 is installed at one end of the screw extruder 11, and the inner side of the extruder 8 is provided with a filamentary forming port 9, and a support rod 10 is installed at the position where the upper end of the processing tank 12 contacts the screw extruder 11.

[0033] Further, the upper end of the processing device main body 1 is equipped with a feeding seat 1...

Embodiment 3

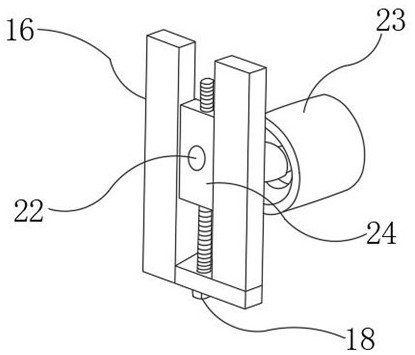

[0036] On the basis of Example 2, such as figure 1 , 5 , shown in 6, a kind of elastic composite polyester fiber filament processing device, comprises processing device main body 1, and one side of processing device main body 1 is installed No. 1 seat body 4 and No. 2 seat body 6, and the bottom of processing device main body 1 is installed There is a device bottom plate 5, and the inner side of No. 1 seat body 4 and No. 2 seat body 6 is provided with a processing groove 12, and the inner side of the processing groove 12 is installed with an extruder drive seat 14, and one end of the extruder drive seat 14 is installed with a screw extruder. Extruder 11, one end of the screw extruder 11 is equipped with an extrusion head 8, the inner side of the extrusion head 8 is provided with a filamentary forming port 9, and the upper end of the processing tank 12 is in contact with the screw extruder 11. A support rod is installed 10.

[0037] Further, a No. 1 positioning connector 31 a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com