Two-sided release paper and production method thereof

A production method and release paper technology, applied in the production of microfiber leather, leather, and synthetic leather, can solve the problems of affecting the appearance of leather, high import cost of release paper, and increase the manufacturing cost of patterned leather products, etc. Tensile strength and flexural resistance, ease of winding operation and repeated use, and the effect of improving the reuse rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] Embodiments of the present invention will be further described below in conjunction with accompanying drawings:

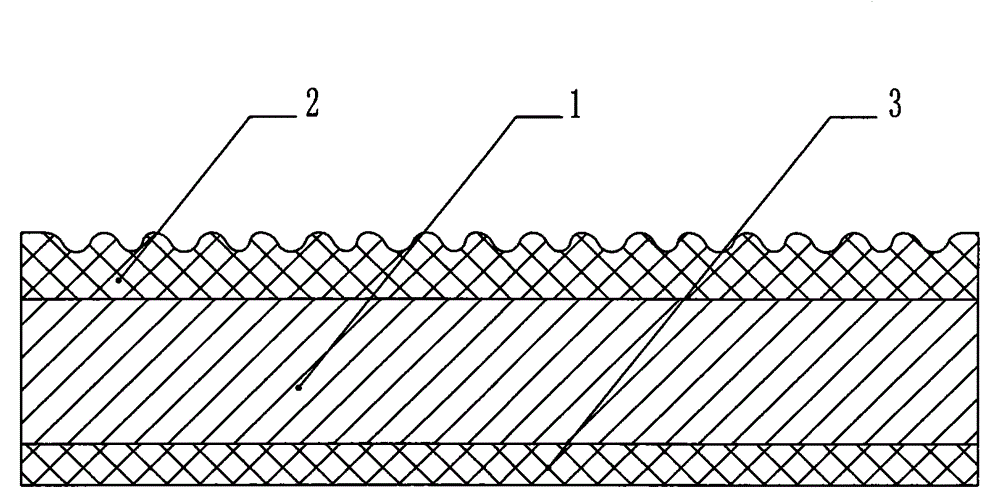

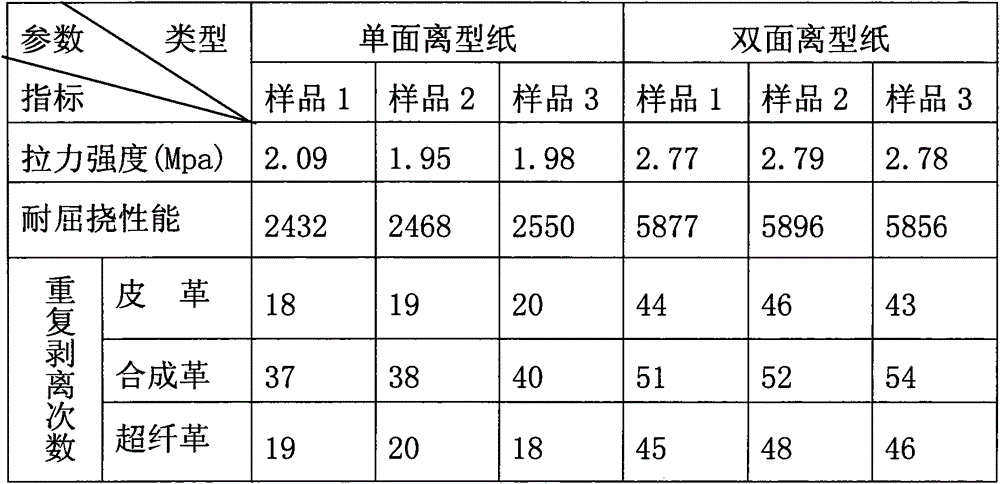

[0018] Such as figure 1 As shown, the present invention is a double-sided release paper, comprising a base paper base 1, a patterned resin layer 2 is arranged on the surface of the base paper 1, the patterned resin layer 2 is arranged on the front side of the base paper 1, and the base paper There is a balance resin layer 3 on the back of the base layer 1; the pattern resin layer 2 and the balance resin layer 3 are spray-coated on the front and back of the base paper base 1, so that the tensile strength and flex resistance of the release paper can be greatly improved performance, so that the peeling times of the release paper can be significantly increased, the reuse rate of the release paper is greatly improved, and the delamination of the patterned resin layer can be effectively avoided, and the longitudinal and transverse tearing degree and longitudinal t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com