Novel rolling-drawing die frame

A roll-pulling and die-set technology, applied in the field of roll-pull die set, can solve the problems of limiting the use range of profiles, the disc shape of profiles, the flatness, and the difficulty of stable control of ring diameter, so as to improve the processing quality and improve the stretching effect. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

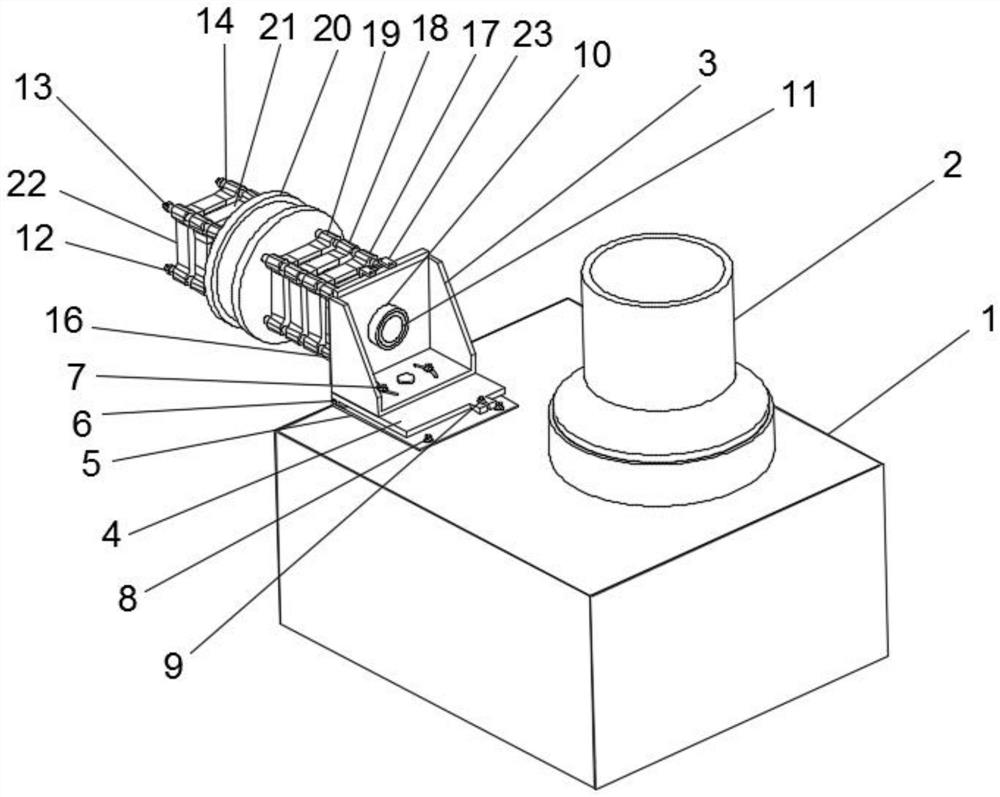

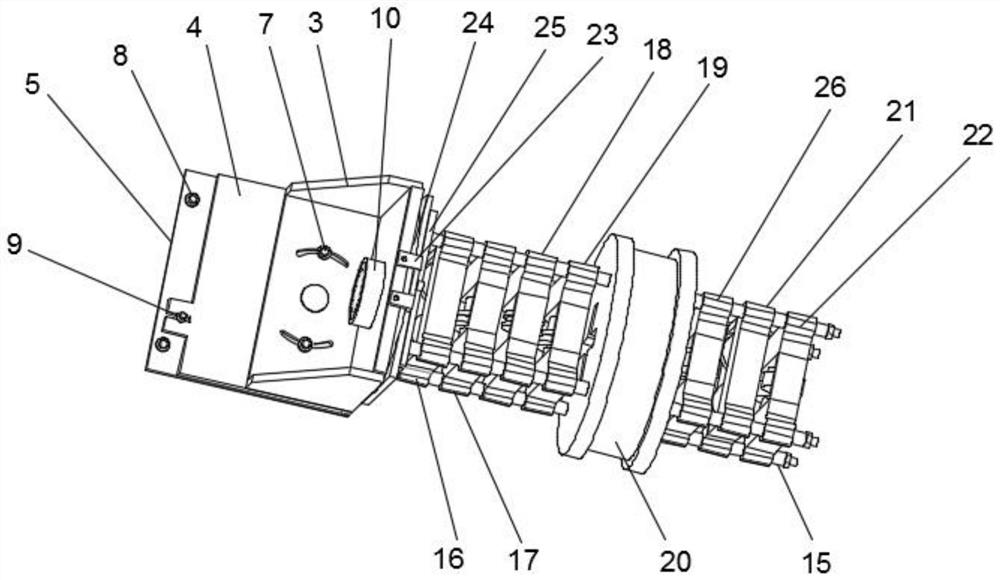

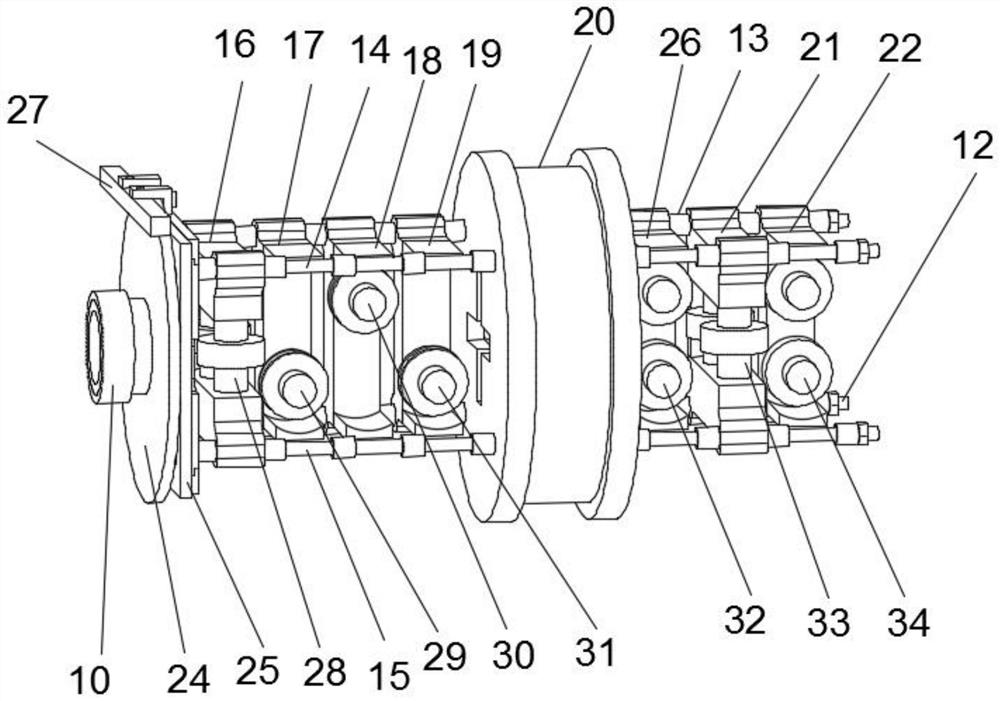

[0034] Such as Figure 1-5As shown, a new type of rolling formwork includes a support base 1, a roller 2, a connecting frame 3, a rotating plate 24, a first screw 12, a second screw 13, a third screw 14, a fourth screw 15 and a rolling mechanism 20. The roller 2 is installed on the upper end of the support base 1 near the front, the connecting frame 3 is connected to the upper end of the supporting base 1 near the rear, and the rotating plate 24 is rotatably connected to the rear end of the connecting frame 3 close to In the middle position, the middle position of the rear surface of the connecting frame 3 is provided with a connecting groove, the front end of the rotating plate 24 is fixedly connected with the limit ring 11, and the outer surface of the connecting frame 3 is fixedly equipped with a connecting ring 10;

[0035] The rear end of the rotating plate 24 is fixedly connected with a fixed plate 25, and the first screw 12, the second screw 13, the third screw 14 and t...

Embodiment 2

[0044] The working method of this novel rolling formwork comprises the following steps:

[0045] Step 1: pass the processing material between several fifth straightening rollers 34, between the second vertical rollers 33 and between the fourth straightening rollers 32, and pass through the rolling mechanism 20 through the rolling groove, and pass through the first A rolling wheel 35, a second rolling wheel 36, a third rolling wheel 37 and a fourth rolling wheel 38 roll the processing material, and the processing material is passed through the third straightening roller 31, the second straightening roller 30 and the straightening wheel on the first straightening roller 29 straighten the processed material;

[0046] Step 2: Pass the processing material through the positioning wheels on several first vertical rollers 28 for positioning, pass through the rotating plate 24 and the limit ring 11 and the drum 2 to wind and take up the wire, and after the processed material is taken u...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com