Equipment abnormality handling timing determination system, equipment abnormality handling timing determination method, and storage medium

A technology for abnormal and abnormal equipment, applied in manufacturing computing systems, general control systems, control/regulation systems, etc., and can solve problems such as unconsidered margin time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0042] Hereinafter, an embodiment of an equipment abnormality handling timing determination system according to the present invention will be described with reference to the drawings.

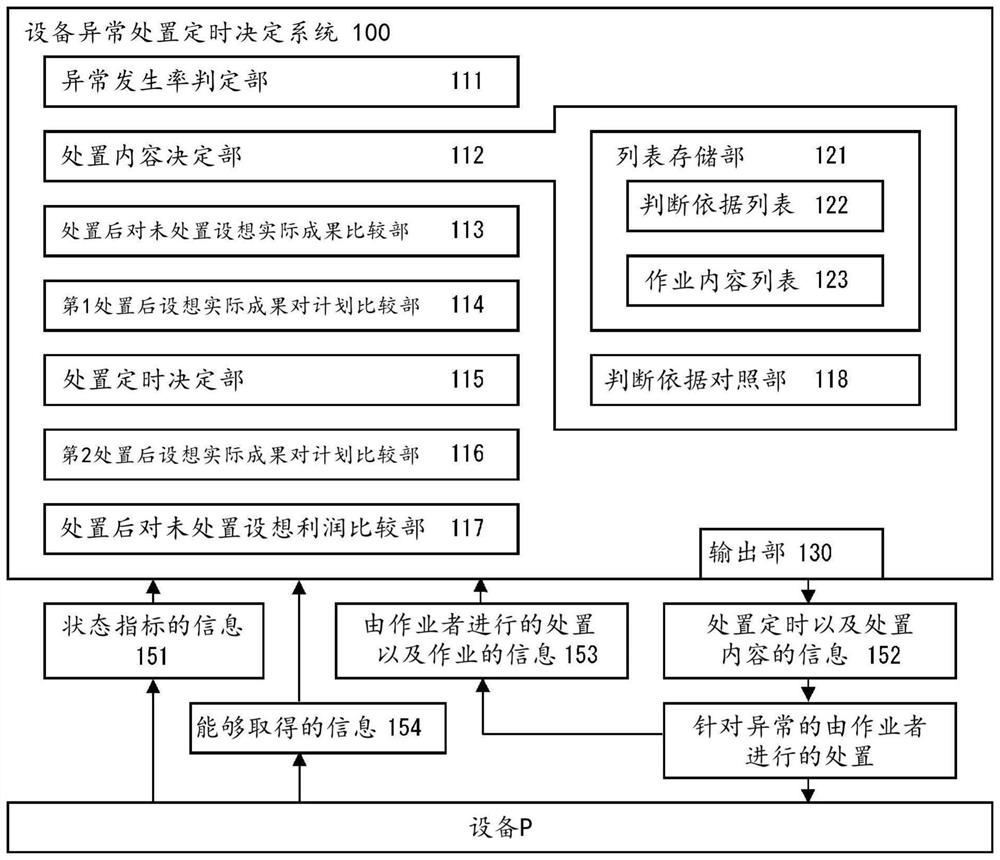

[0043] figure 1 It is a block diagram showing a schematic configuration of an equipment abnormality handling timing determination system 100 according to an embodiment of the present invention. The equipment abnormality handling timing determination system 100 can output the timing and action content information 152 from the output unit 130 when it is determined that action to the abnormality is necessary based on the state index information 151 about the equipment P.

[0044] In one embodiment, the equipment abnormality treatment timing determination system 100 includes: an abnormality occurrence rate determination unit 111, a treatment content determination unit 112, an assumed quantity comparison unit 113 after treatment versus an untreated period, and a first post-treatment assumption quant...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com