Multi-section roller brush machine for plastic glove production line

A production line, roller brushing machine technology, applied in applications, household components, household appliances, etc., can solve the problems of high noise, large workload of manual cleaning of hand molds, physical injury of workers, etc., and achieve the effect of avoiding damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Example Embodiment

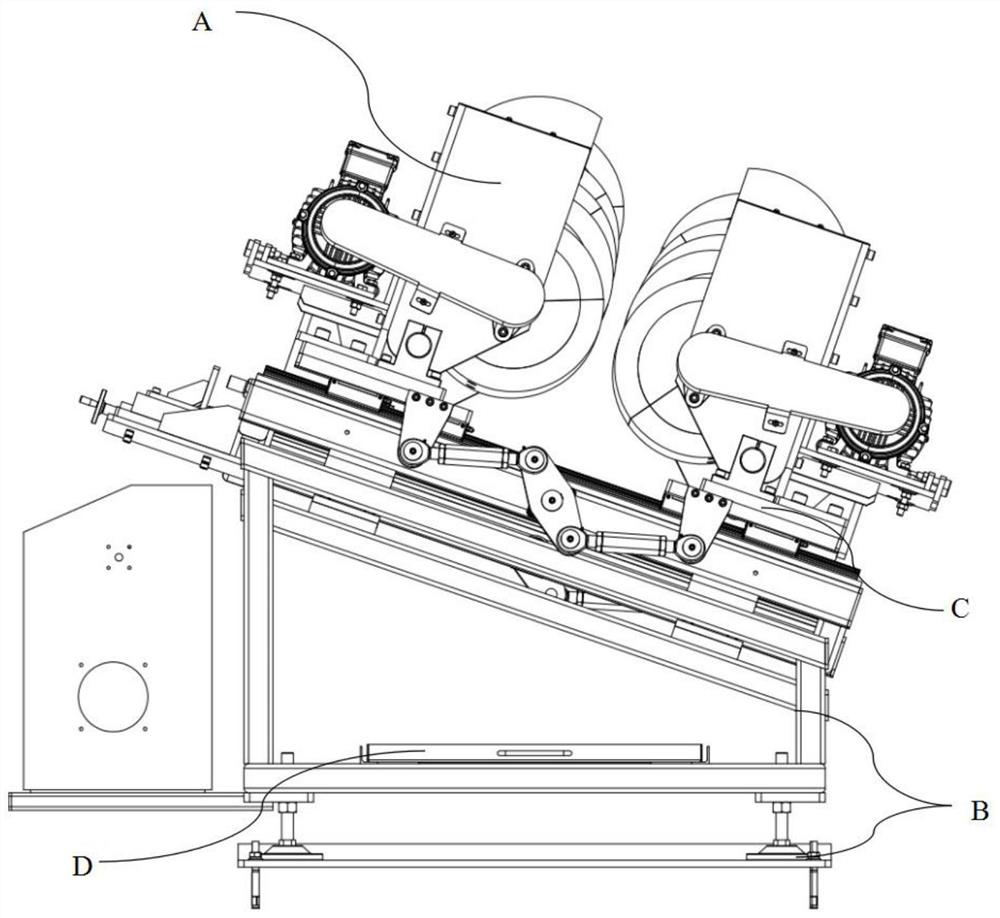

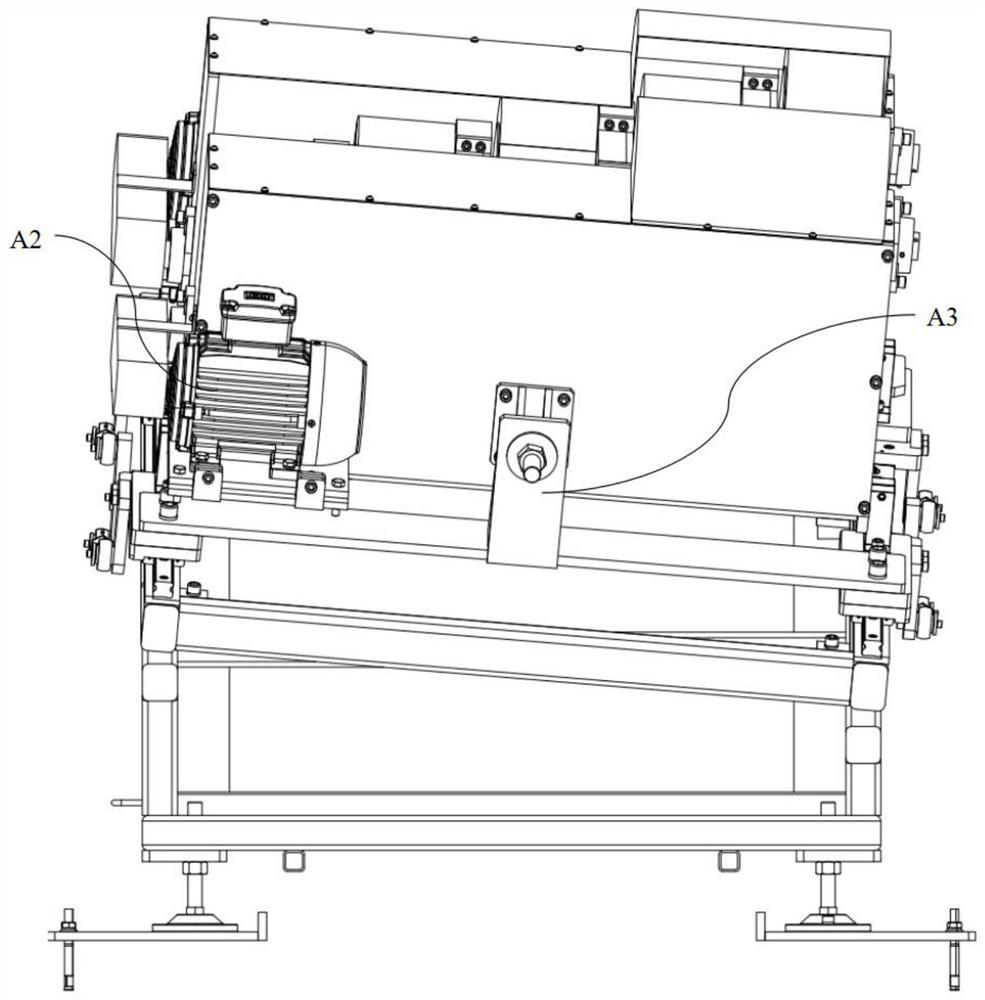

[0022]Such asfigure 1 As shown, the multi-segment roller brush for the present invention includes a roll brush assembly A, a bracket assembly B, and a drive mechanism C, and the roller brush assembly A is mounted on the bracket assembly B, and the roller brush assembly A includes two sides along the hand mold. Distributed, and multiple roll brushes arranged in each side. The multi-segment roller brush provided in this embodiment also includes a tape cartridge D, a tape cartridge D is disposed on the bottom bracket and the hand mold is applied to a glove of the roller brush.

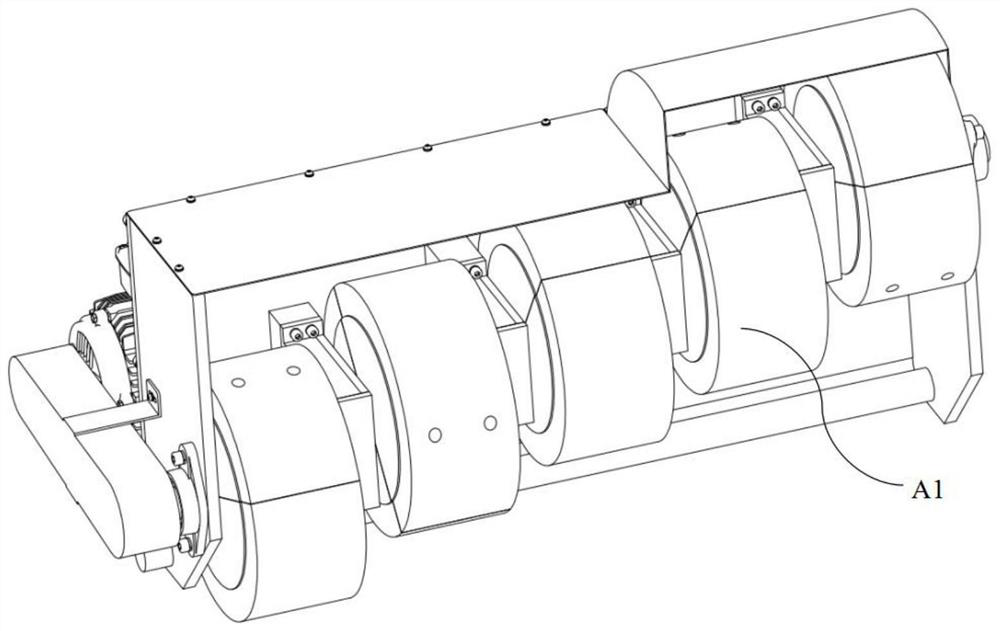

[0023]Seefigure 2 Each roll brush in the stepped roller brush is installed separately, and each roll brush A1 can be separately disassembled. If used during use, it is necessary to replace a single roller brush, exemption of overall demolition. The plurality of roller brush A1 coincides with high to low in the direction of motion and the direction of rotation, from the top to the lower one, and then brush the wris...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com