Device for comminuting loose feed material

An equipment and grinding technology, applied in the field of feeding equipment, can solve the problem that the grinding equipment is not fully utilized, and achieve the effect of optimizing the possibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

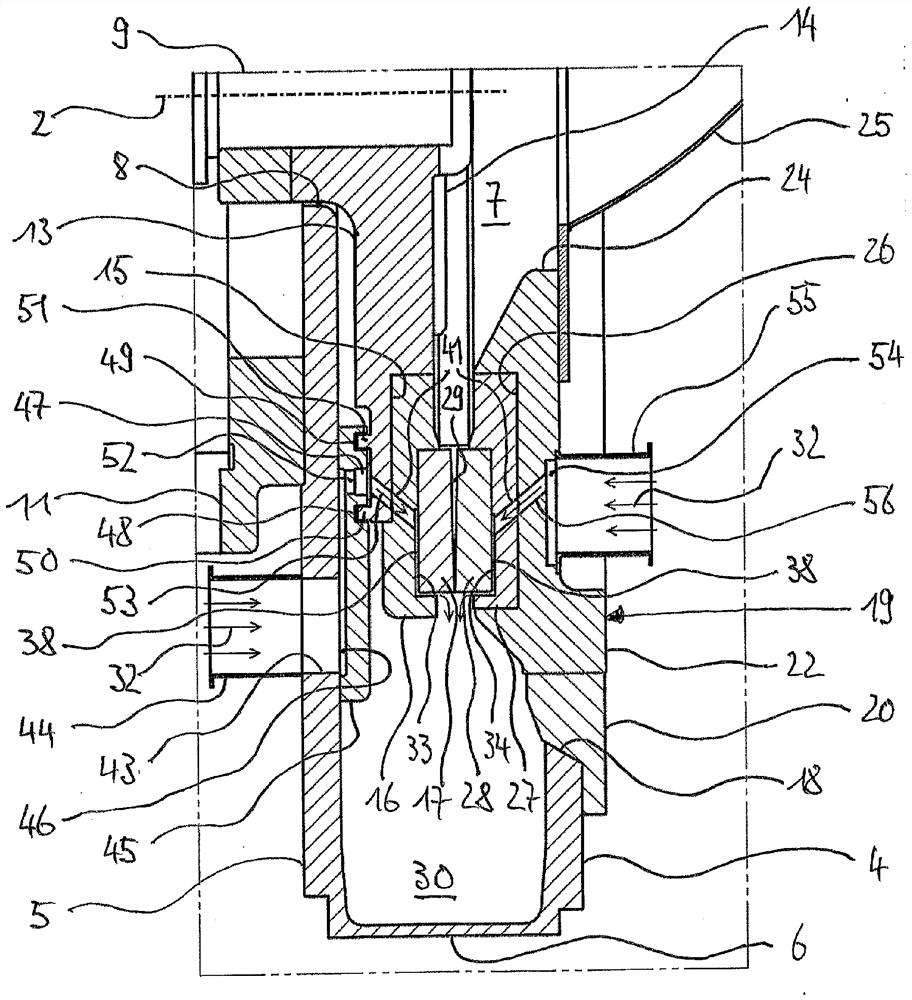

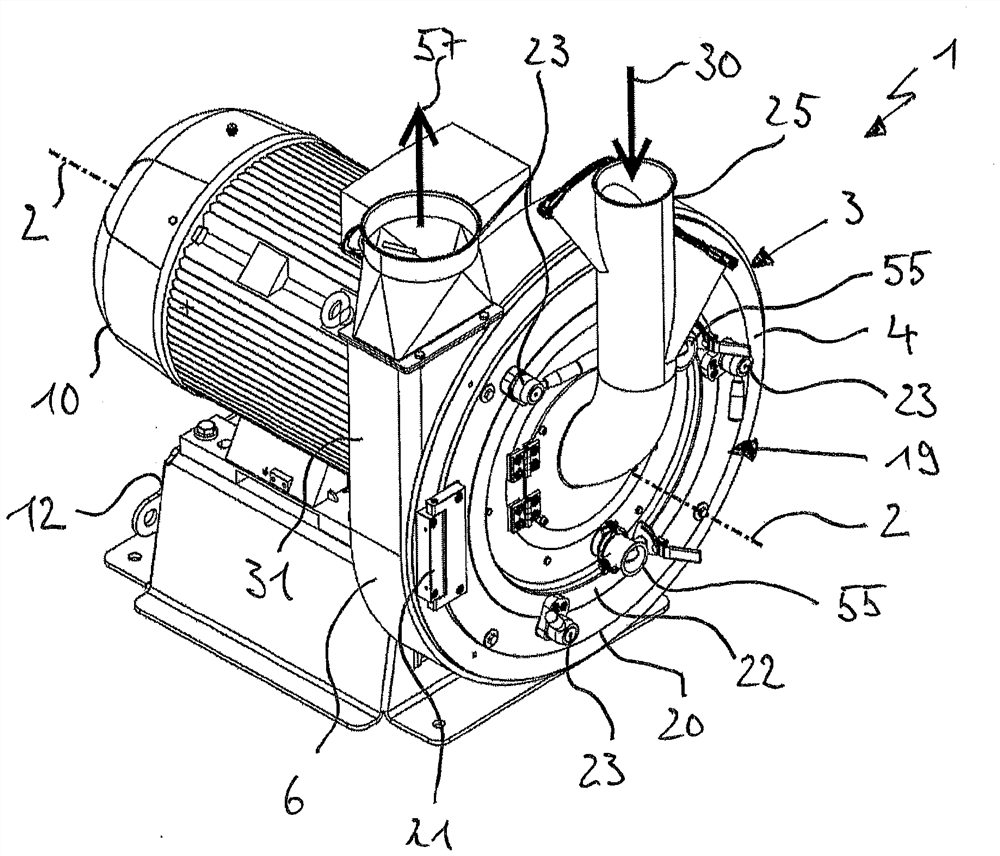

[0023] Figures 1 to 3 The basic structure of the device according to the invention in the form of a disc refiner 1 is shown. The disc refiner 1 has a substantially drum-shaped housing 3 surrounding an axis 2 with a front wall 4, a rear wall 5 axially spaced therefrom and a housing casing 6 connecting the front wall 4 and the rear wall 5, which Surround the crushing space 7 together.

[0024] In the region of the axis 2 , the rear wall 5 has a housing opening 8 coaxial with respect to the axis 2 , through which the end of the drive shaft 9 of the drive unit extends. In the present embodiment, the drive shaft 9 is formed directly by the rotor shaft of the electric motor 10 , but it can also be driven as a separate shaft indirectly via a belt drive or other transmission means. The housing 3 is rigidly connected via an annular flange 11 concentrically surrounding the housing opening 8 to an electric motor 10 , which in turn rests on a stationary base 12 .

[0025] especially f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com