Method for producing cooled power electronics module

A technology for power electronic modules and cooling channels, applied in semiconductor/solid-state device manufacturing, circuits, electrical components, etc., can solve problems such as damage to eddy currents, and achieve stable manufacturing or connection effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

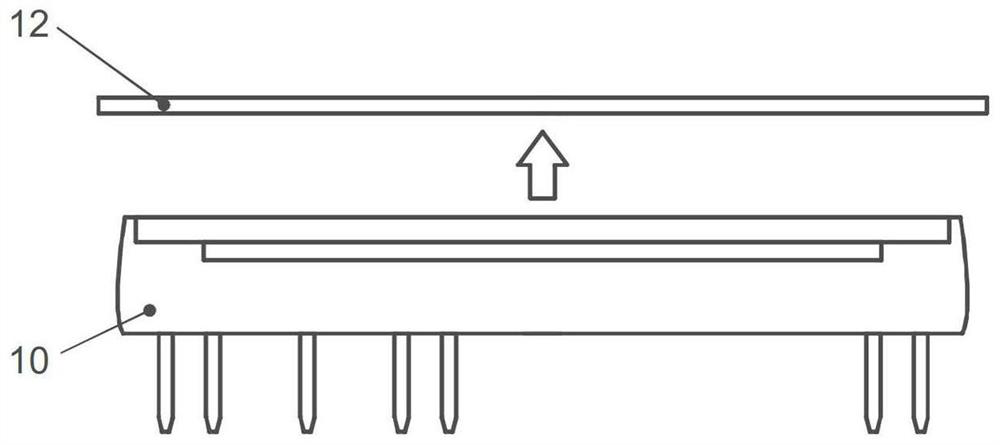

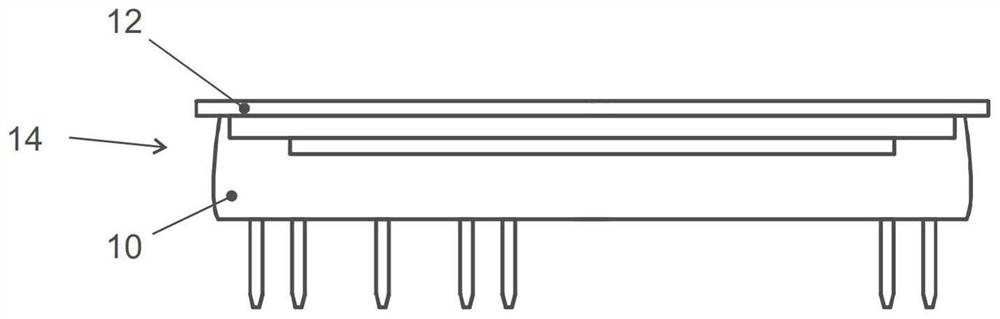

[0028] figure 1 The thermal and mechanical connection of the electronic component 10 to the cooling channel cover 12 designed as a flat sheet metal is schematically shown. The details of the electronic component 10 are not important in the context of the present invention. In particular, however, it may be a switching element for power electronics for the operation of a traction machine of a motor vehicle. Preferably, the electronic component 10 is in its figure 1 The upper side shown in the middle pointing upwards has a sinterable coating which is sintered with the corresponding material on the lower side of the cooling channel cover 12 in order to thereby produce a tight, material-bonded thermal and mechanical connection. connect. produced as in figure 2 The prefabricated modules 14 shown schematically in .

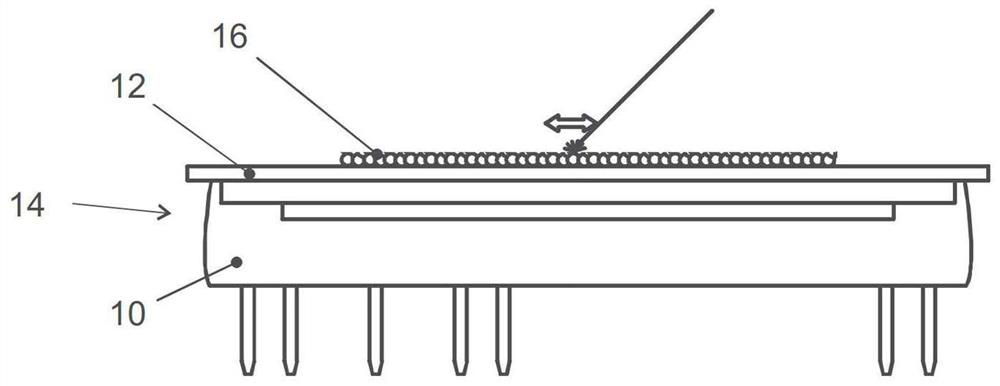

[0029] Next, in image 3 In the method steps shown, the swirler structure 16 is applied to the upper side of the cooling channel cover 12 by means of 3D printing...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com