A simple laser bench clamping device with adjustable inclination angle

A technology of tilt angle and clamping device, which is applied in the direction of auxiliary equipment, laser welding equipment, auxiliary welding equipment, etc., can solve the problems that cannot meet the requirements of laser machining large-angle inclined hole processing technology research, unfavorable research funds, unfavorable experimental research, etc. Achieve the effects of simple and practical mechanical locking method, obvious economic superiority and improved stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be further described below in conjunction with the accompanying drawings.

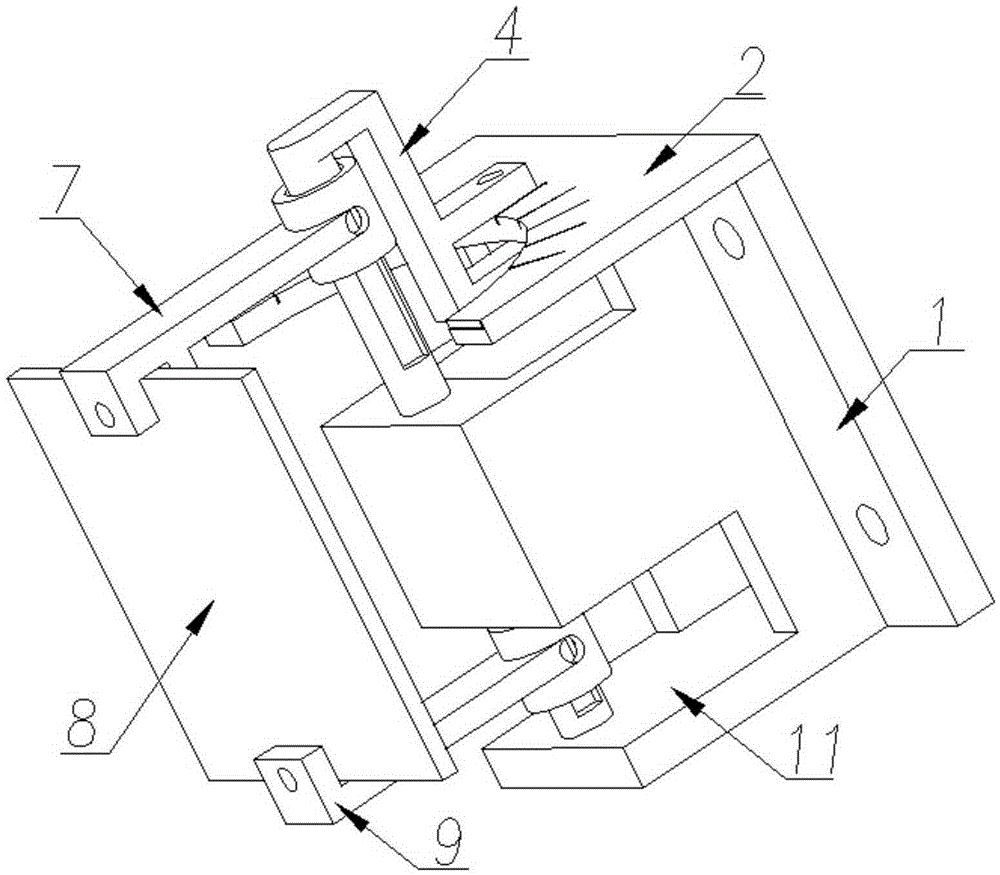

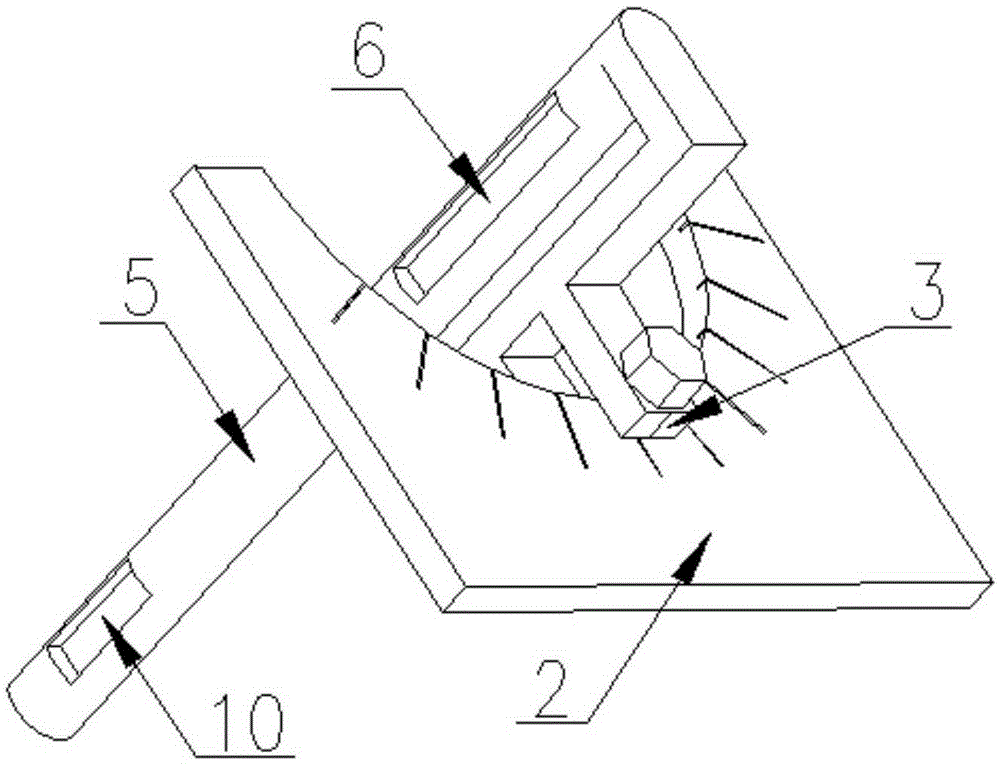

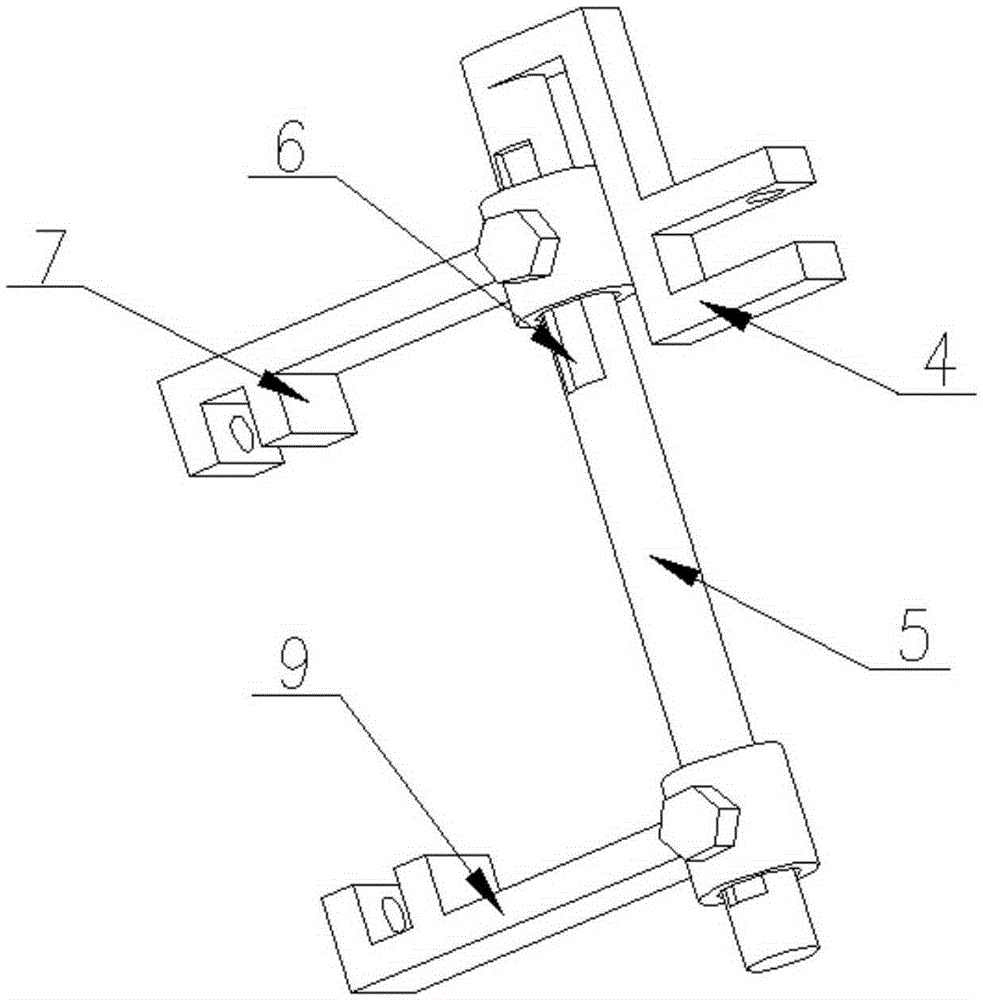

[0017] see figure 1 , a simple laser stand clamping device with adjustable inclination angle, including a base 1, with through holes on the four corners of the base 1, which are fixed on the moving table of the laser stand through bolt connection; the upper cover plate 2 is connected On the upper end of the base 1, the lower cover plate 11 is installed on the lower end of the base 1, the middle part of the main shaft 5 passes through the inner hole of the boss in the middle part of the base 1, the inner hole constrains the radial movement of the main shaft 5, and the lower end of the main shaft 5 is connected to the lower cover plate 11, so that the rotation of the main shaft 5 is more stable, and the upper end is connected with the upper cover plate 2 by bolts through the side clamp 4 welded on the main shaft 5 to constrain the axial movement of the main shaft 5, such...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com