Seam beautifying device with internal corner seam beautifying function

A beautiful seam and functional technology, applied in the direction of architecture and building construction, can solve the problems of difficult manual work, time-consuming and labor-intensive, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

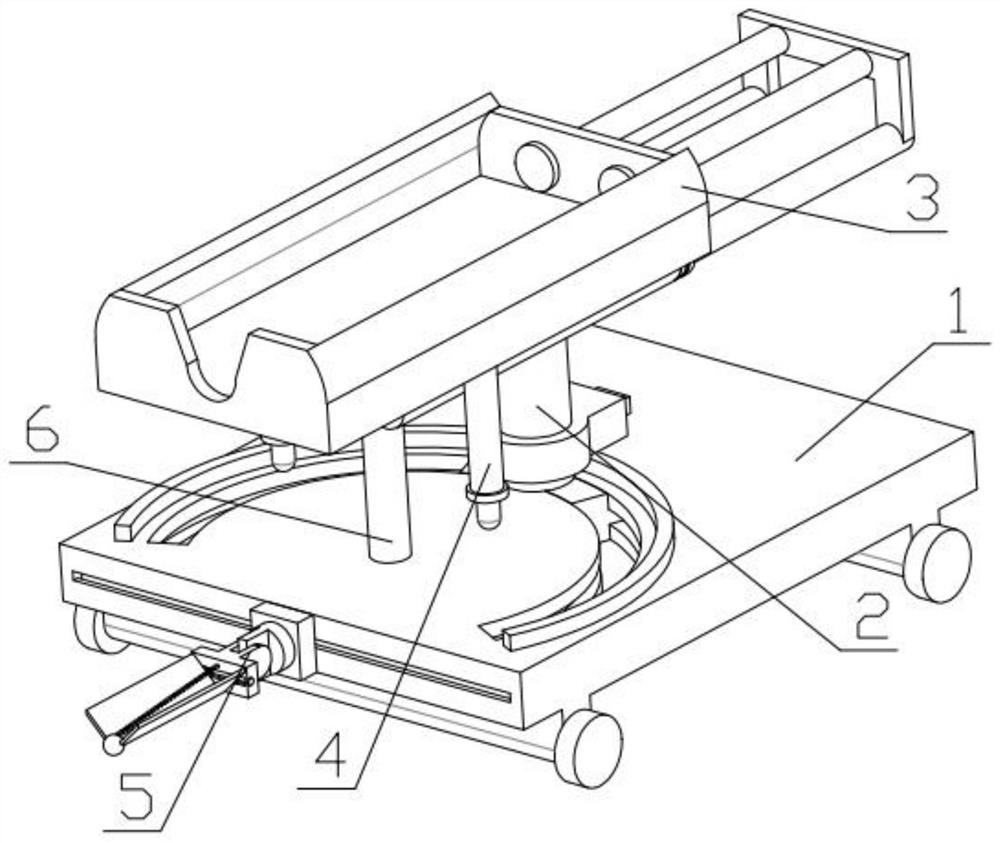

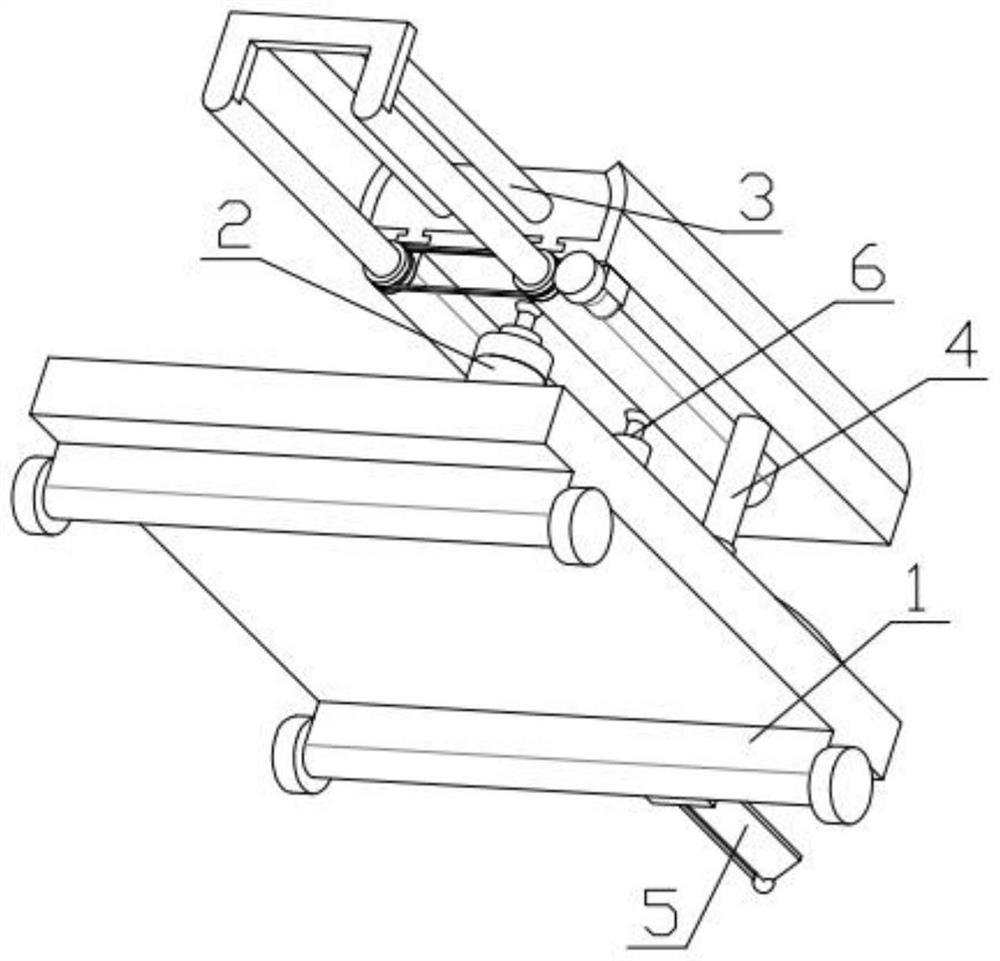

[0038] Combine below Figure 1-18 Describe this embodiment, a beautifying device with the function of beautifying inside corners, including a constant speed moving car 1, an angle adjustment mechanism 2, an automatic beautifying mechanism 3, a balance adjustment structure 4, an adjustable seam pressing mechanism 5 and a central support assembly 6. The adjustable seam pressing mechanism 5 is slidably installed in the groove provided on the constant speed moving car 1, the central support assembly 6 is fixedly installed on the constant speed moving car 1, and the angle adjustment mechanism 2 is slidably installed on the constant speed moving car 1 In the set groove, a central support assembly 6 is installed rolling in the groove of the automatic beautifying mechanism 3, an angle adjustment mechanism 2 is rolled and installed in the groove of the automatic beautifying mechanism 3, and a balance is fixedly installed on the automatic beautifying mechanism 3. Adjust the structure4. ...

specific Embodiment approach 2

[0040] Combine below Figure 1-18 Describe this embodiment, this embodiment will further explain the first embodiment, the angle adjustment mechanism 2 includes a toothed half ring 2-1, an arc-shaped slider 2-2, a fixed shell 2-3, and a pull handle 2-4 , Tooth pattern plug-in 2-5, internal thread shell 2-6, internal thread ring 2-7, internal thread rod 2-8, rolling ball one 2-9, internal spring 2-10, tooth pattern half ring 2-1 fixed Installed on the uniform speed mobile car 1, the arc-shaped slider 2-2 is slidably installed in the groove provided on the uniform-speed mobile car 1, and the arc-shaped slider 2-2 is fixedly installed with an internal thread housing 2-6, and the internal thread housing A fixed shell 2-3 is fixedly installed on the 2-6, and a pulling handle 2-4 is slidably installed in the groove of the fixed shell 2-3, and a tooth pattern plug-in 2-5 is fixedly installed on the pull handle 2-4, and the tooth pattern plug-in 2-5 passes through the fixed shell 2-3...

specific Embodiment approach 3

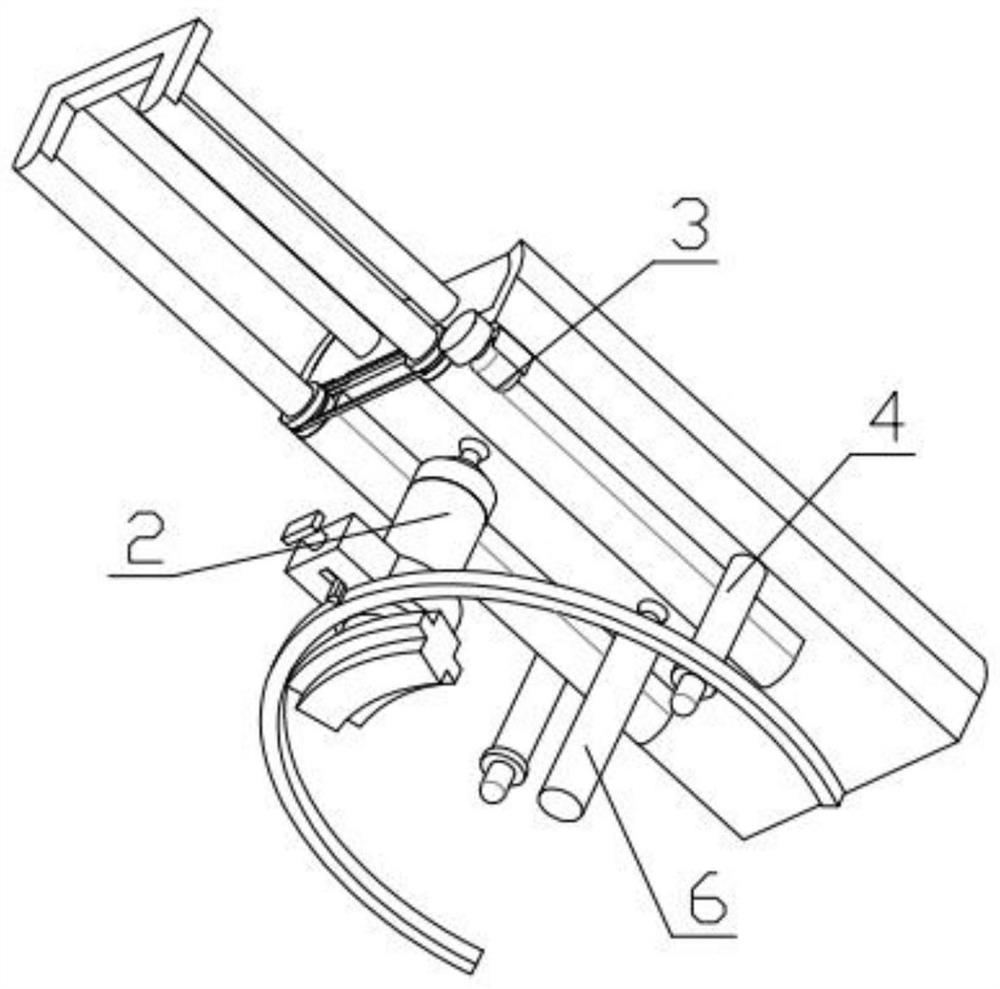

[0042] Combine below Figure 1-18 Describe this embodiment, this embodiment will further explain the second embodiment, the automatic beautifying mechanism 3 includes a glue gun shell 3-1, a track cylinder 3-2, a push motor 3-3, a push gear 3-4, Internally threaded sprocket 3-5, chain 3-6, threaded push rod 3-7, glue gun push rod 3-8, glue gun shell 3-1 is fixedly installed with track tube 3-2, track tube 3-2 Internally threaded sprocket 3-5 is installed in the groove, internally threaded sprocket 3-5 meshes with chain 3-6, internally threaded sprocket 3-5 meshes with push gear 3-4, pushes gear 3-4 Fixedly installed on the output end of the push motor 3-3, the push motor 3-3 is fixedly installed on the glue gun shell 3-1, the threaded push rod 3-7 is slidably installed in the groove provided on the track cylinder 3-2, the thread The push rod 3-7 is threadedly connected with the internally threaded sprocket 3-5, and the threaded push rod 3-7 is fixedly equipped with a glue gun...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com