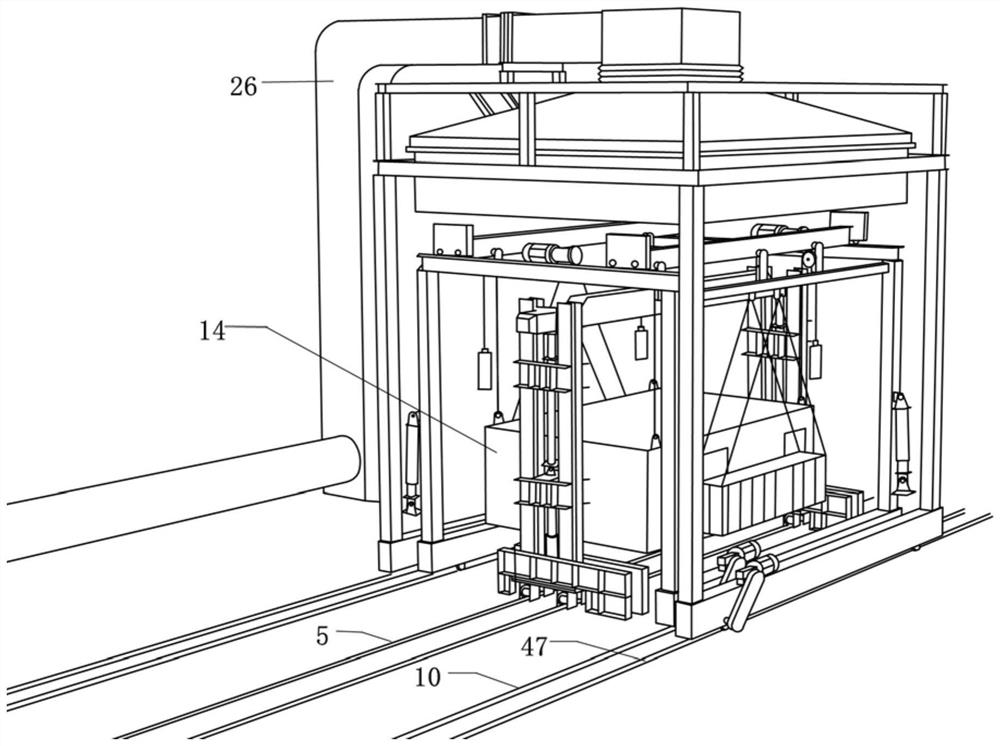

A Cascade High Energy Earthquake-Fire Coupling Test System

A test system and high-energy technology, applied in vibration testing, machine/structural component testing, instruments, etc., can solve problems such as unusable loading beams, high technical difficulties, and model damage, so as to avoid manual work at high altitudes and solve the problem of net height Effect of limitation and reduction of hoisting weight

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

[0091] This embodiment also provides an implementation method of a cascaded high-energy earthquake-fire coupling test system, taking the component "pseudo-static-fire" coupling test as an example, specifically including the following steps:

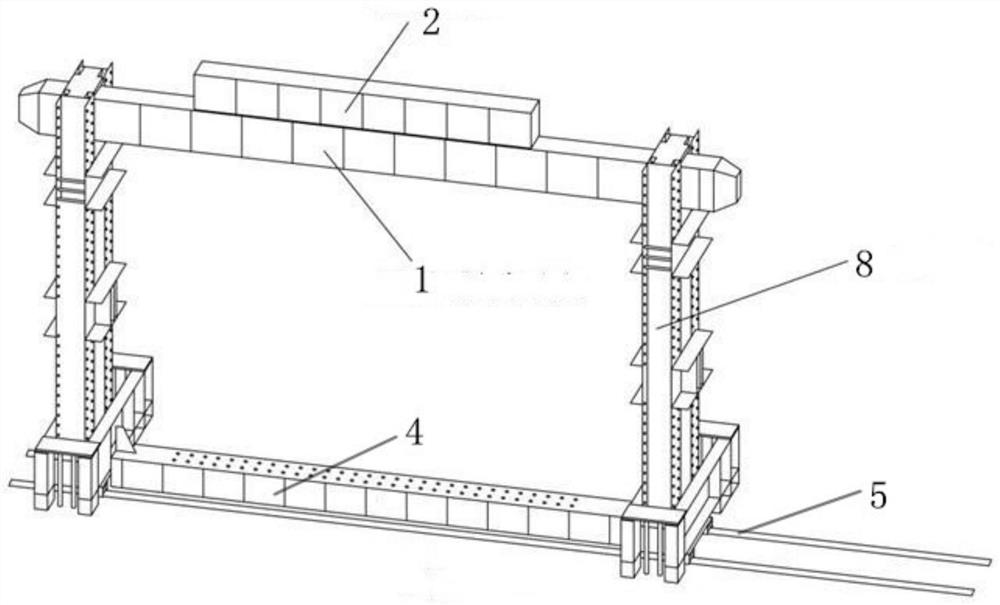

[0092] 1) Hoist the test piece into the self-balancing loading system, loosen the anchor bolts of the anchor steel beam 84, and raise each walking jacking cylinder 853 synchronously. After the walking jacking cylinder 853 is raised to the predetermined position, the steel beam walking device The frame pulley block 854 of 85 moves along the first track 5, and moves the two movable reaction force frames 8 to appropriate positions according to the size of the test piece;

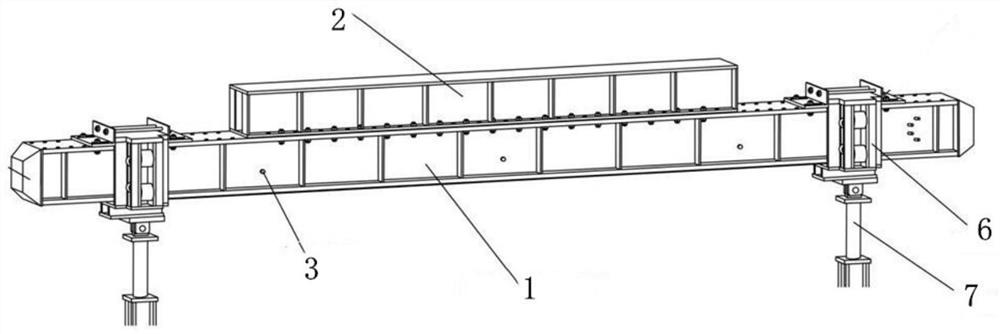

[0093] 2) Loosen the connection between the frame main beam 83 and the H-shaped steel column 81, drive the column lifting cylinder 99 to adjust the high-temperature self-sensing loading beam 1 to the specified height, and drive the actuator 7 to make the high-temperature se...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com