Printing control method, device and computer readable storage medium

A printing control and printing head technology is applied in the fields of devices, computer-readable storage media, and printing control methods, and can solve problems such as the lifting of the printing head, the wrong number of pressing steps, and the wrong pressure control.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

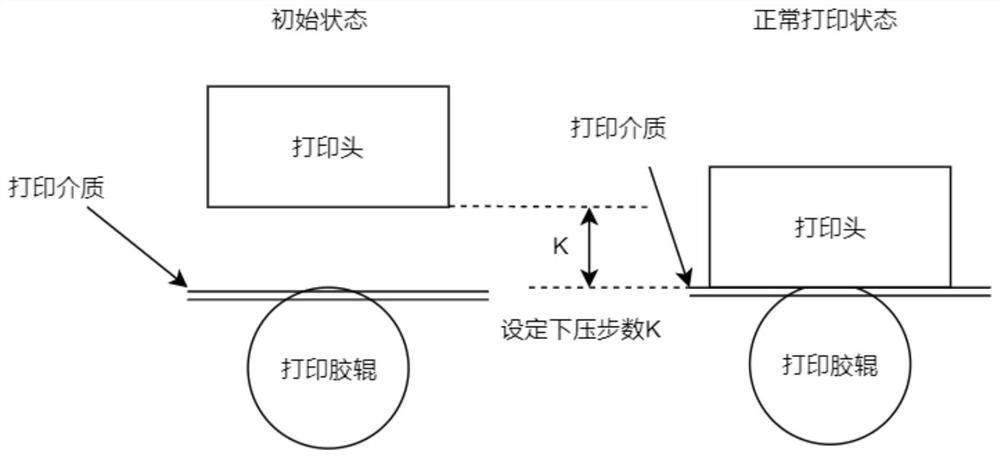

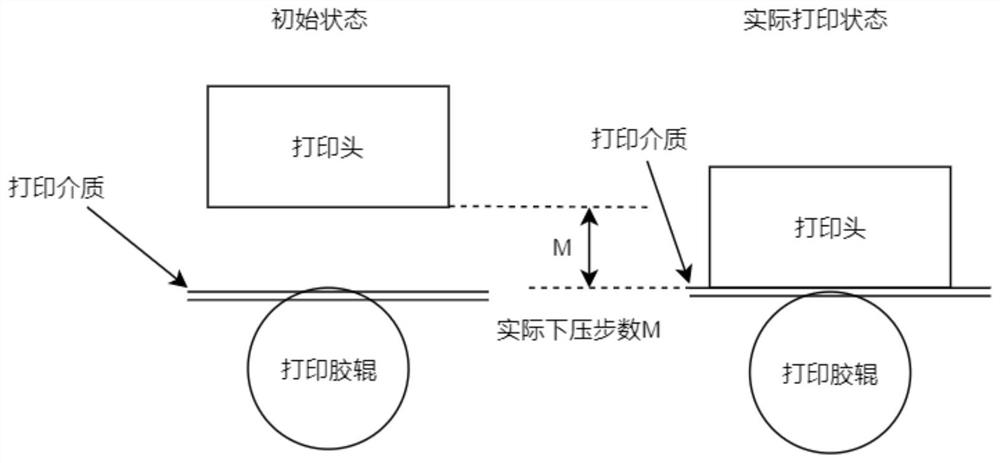

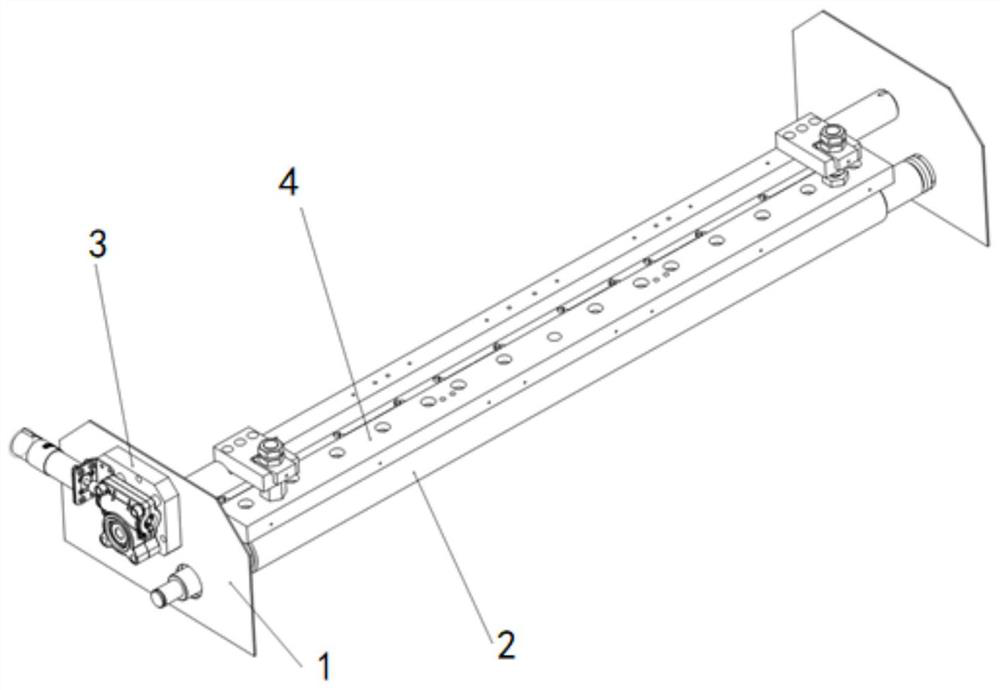

[0049] Such as Figure 1-7 As shown, a printing control method of the present invention includes:

[0050] S1. Obtain the signal data of the Hall sensor;

[0051] S2. Obtain a first parameter and a second parameter of the print head according to the signal data of the Hall sensor; wherein, the first parameter is the number of times the print head is pressed down, and the second parameter is the number of times the print head is lifted.

[0052] S3. According to the first parameter and the second parameter, determine whether to adjust the printing head to continue to press down.

[0053] S1 acquires the signal data of the Hall sensor, including: S11, acquires the relationship between phase A and phase B of the Hall sensor.

[0054] S2 Obtain the first parameter and the second parameter of the print head according to the signal data of the Hall sensor, including:

[0055] S21. According to the relationship between phase A and phase B, determine whether the movement of the pri...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com