Ink pressure controller for ink-jet head

A technology of pressure control and inkjet head, which is applied in printing and other directions, and can solve the problems of increasing the difficulty of manufacturing and assembly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

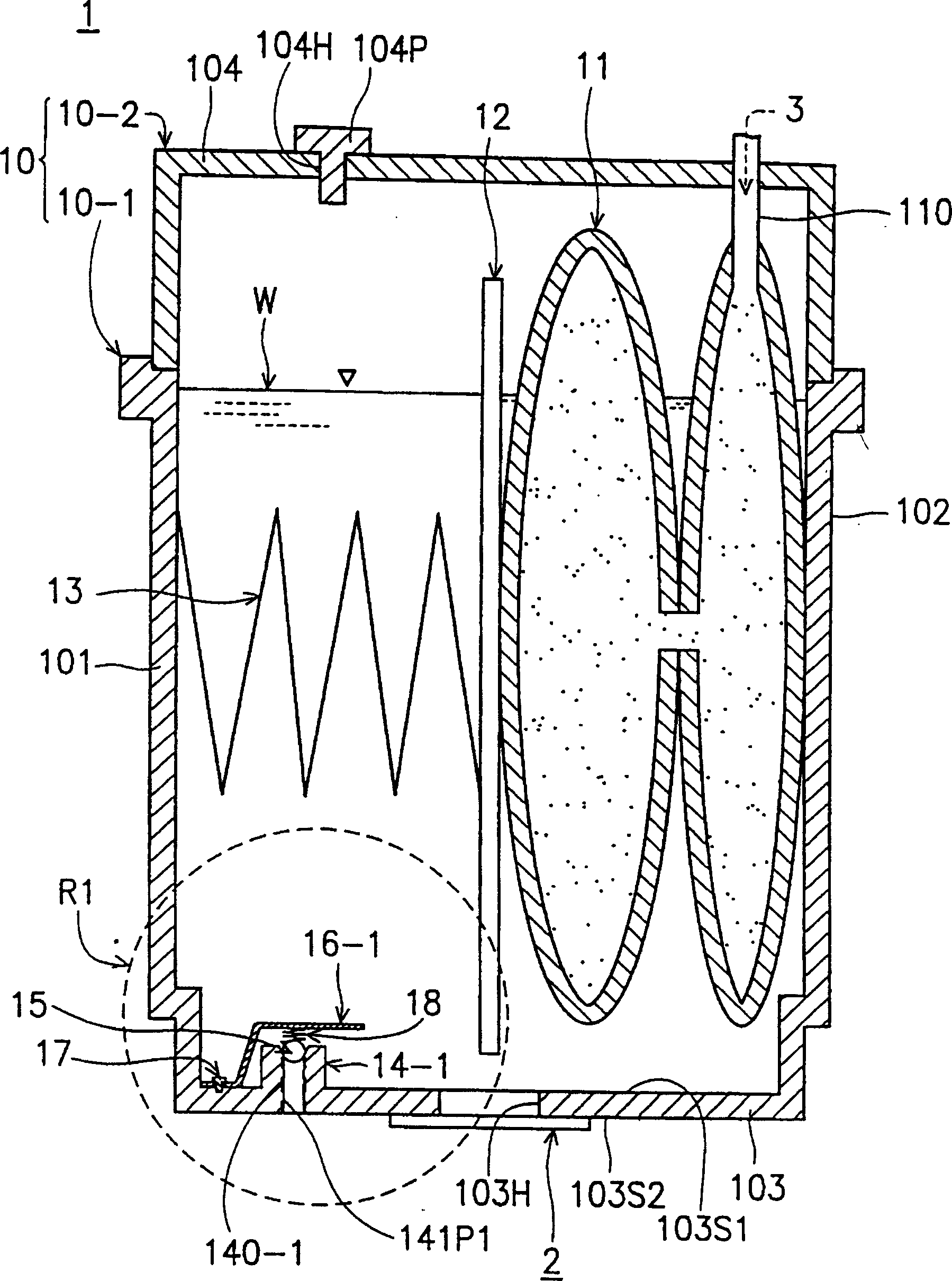

[0033] see Figure 1A , 1B shown.

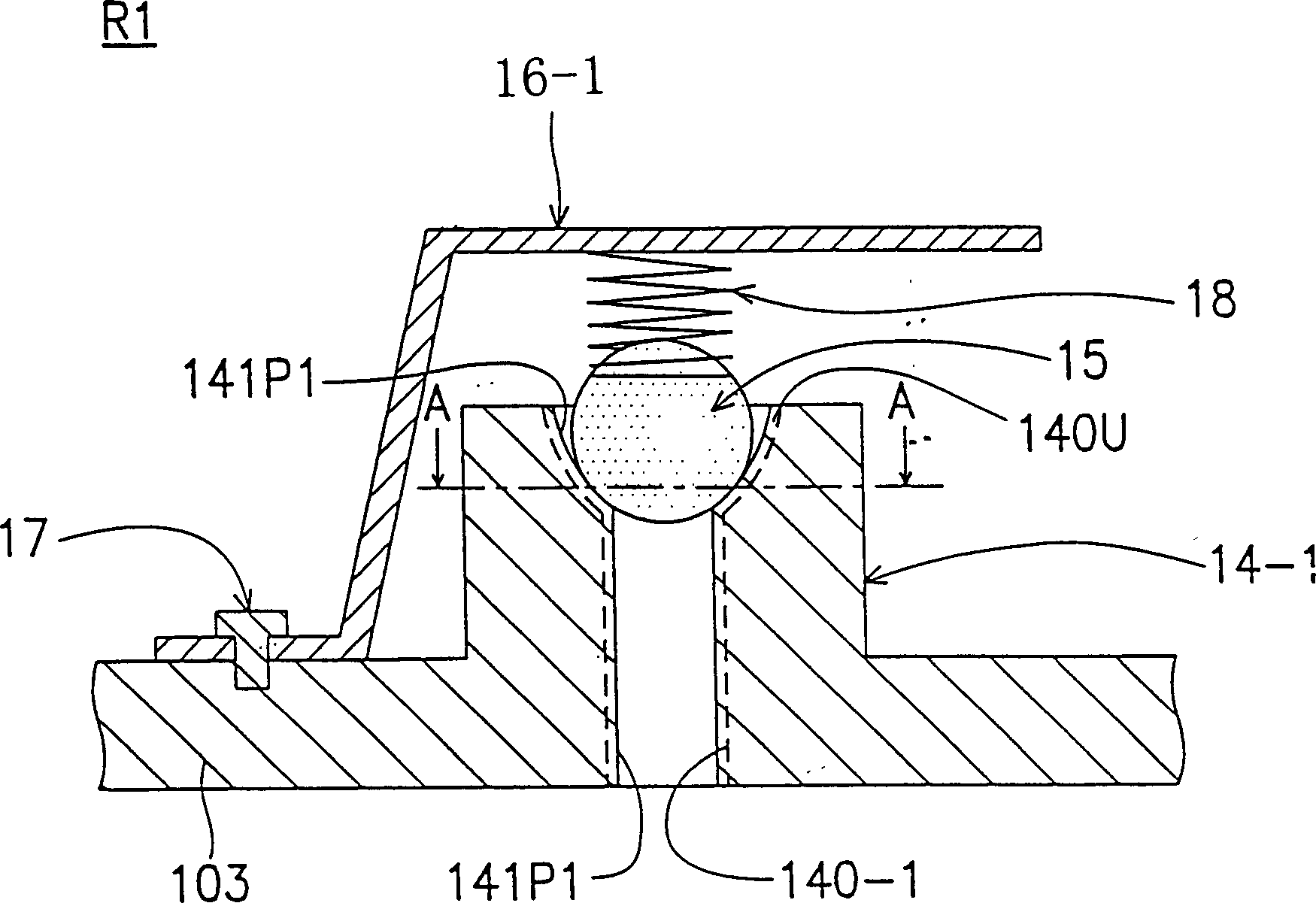

[0034] Figure 1A A schematic view showing an ink cartridge 1 according to a first embodiment of the present invention, Figure 1B According to Figure 1A An enlarged view of the regulator R1.

[0035] Such as Figure 1A As shown, the ink cartridge 1 includes a container 10, an air chamber 11, a plate 12, a spring 13 and a print head 2, wherein the container 10 is used to hold ink W, and the ink cartridge 1 can provide a printing device (not shown) Shown) the required ink W, and there is a negative pressure in the gas inside the container 10. The container 10 has a through hole 140 - 1 (at the bottom of the container 10 ), and the through hole 140 - 1 is an air hole of the container 10 .

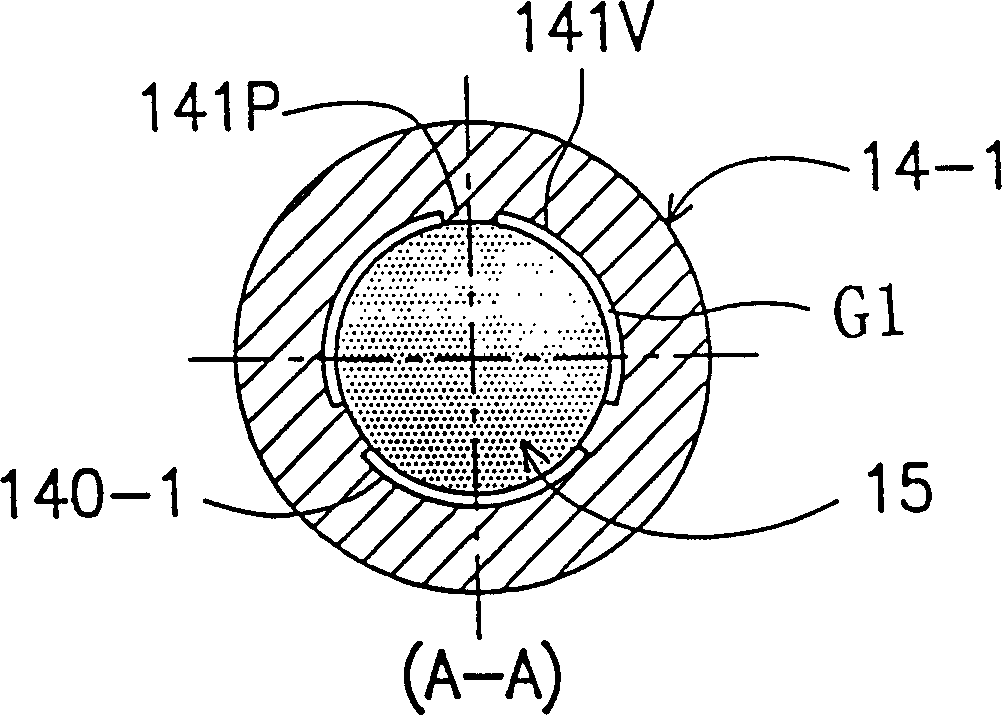

[0036] The ink pressure control device of the inkjet head of the present invention is arranged on the ink cartridge 1, and the ink pressure control device of the inkjet head mainly includes a base 14-1 and a regulating device R1 (the dotted line positio...

Embodiment 2

[0059] see Figure 3A , 3B .

[0060] Figure 3A A schematic view showing an ink cartridge 1' according to a second embodiment of the present invention, Figure 3B According to Figure 3A Enlarged view of the regulator R2.

[0061] Such as Figure 3A , 3B As shown, the difference from the first embodiment is that the ink cartridge 1' is replaced by an elastic element 16' to replace the plate 16-1, and the elastic element 16' presses the stuffing element 15 into contact with several protrusions Above 141P2.

[0062] The elastic element 16' is composed of a reed, and the elastic element 16' is bonded and fixed on the bottom plate 103 by means of a bonding material 17 or by thermal fusion. The elastic element 16' can be divided into a first section 16'-1 and a second section 16'-2, wherein the first section 16'-1 is used to abut the stuffing element 15 against several protrusions in the accommodation chamber 140U On the portion 141P, the second section 16 ′ - 2 abuts aga...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com