Substrate conveyance robot, and method for teaching edge position of target body

一种边缘位置、示教方法的技术,应用在机械手、输送机物件、运输和包装等方向,能够解决难基板应用等问题

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

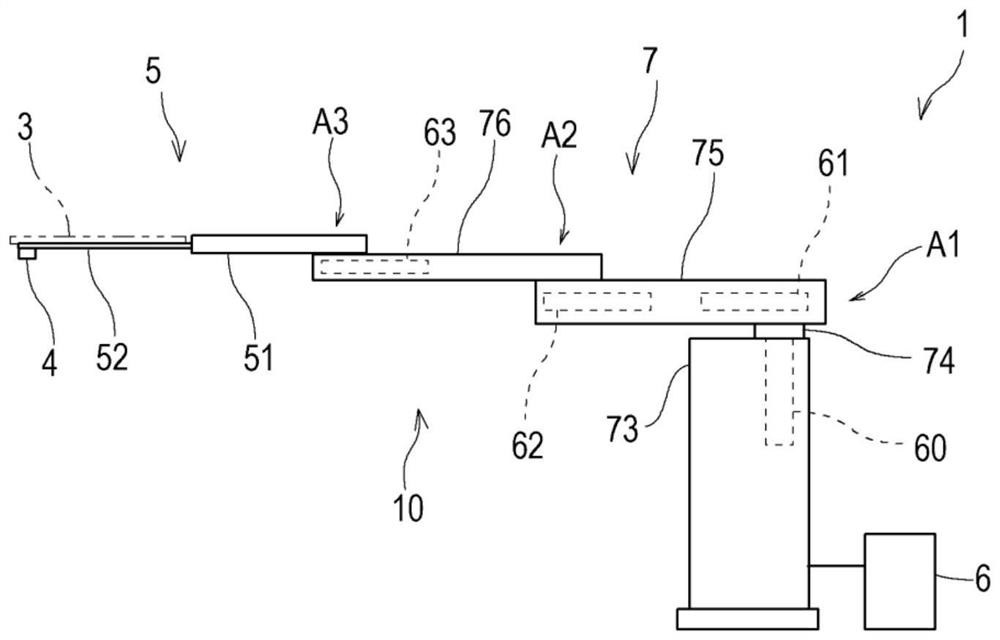

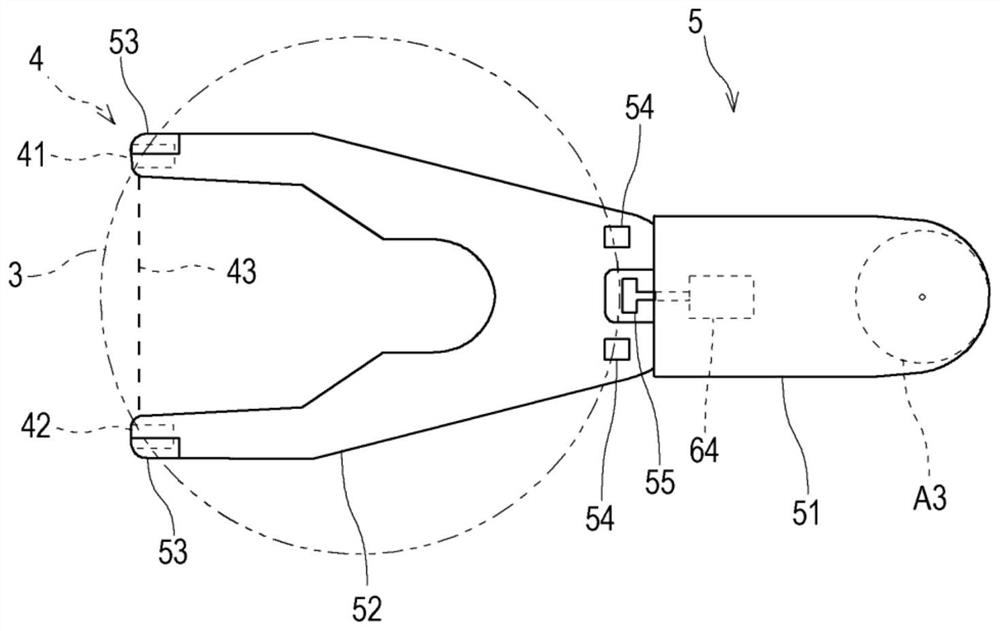

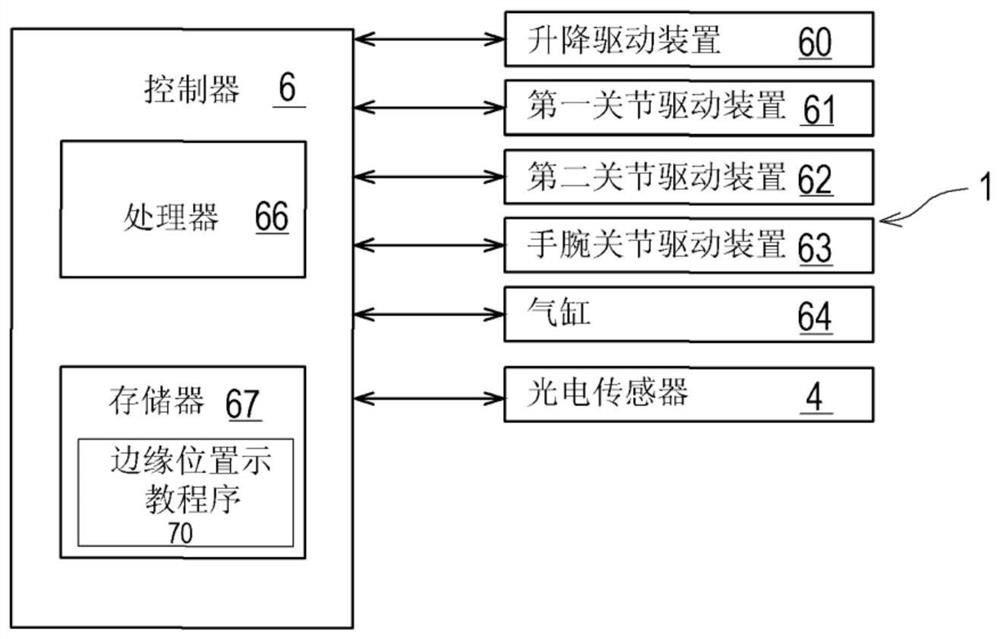

[0027] [Schematic structure of substrate transfer robot 1]

[0028] figure 1 It is a schematic side view of the substrate transfer robot 1 according to one embodiment of the present invention, figure 2 Yes figure 1 A plan view of the hand 5 included in the substrate transfer robot 1 shown. figure 1 as well as figure 2 The illustrated substrate transfer robot 1 includes a robot main body 10 and a controller 6 for controlling the operation of the robot main body 10 . The substrate transfer robot 1 is used to carry in (load) and carry out a substrate 3 from a substrate mounting section not shown. For example, the substrate transfer robot 1 may be provided in a system for transferring various substrates 3 such as EFEM (Equipment Front End Module), a sorter, and a substrate processing system.

[0029] [Structure of robot main body 10]

[0030] The robot main body 10 has: a base 73; a horizontal articulated robot arm (hereinafter referred to as "arm 7") supported on the base...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com