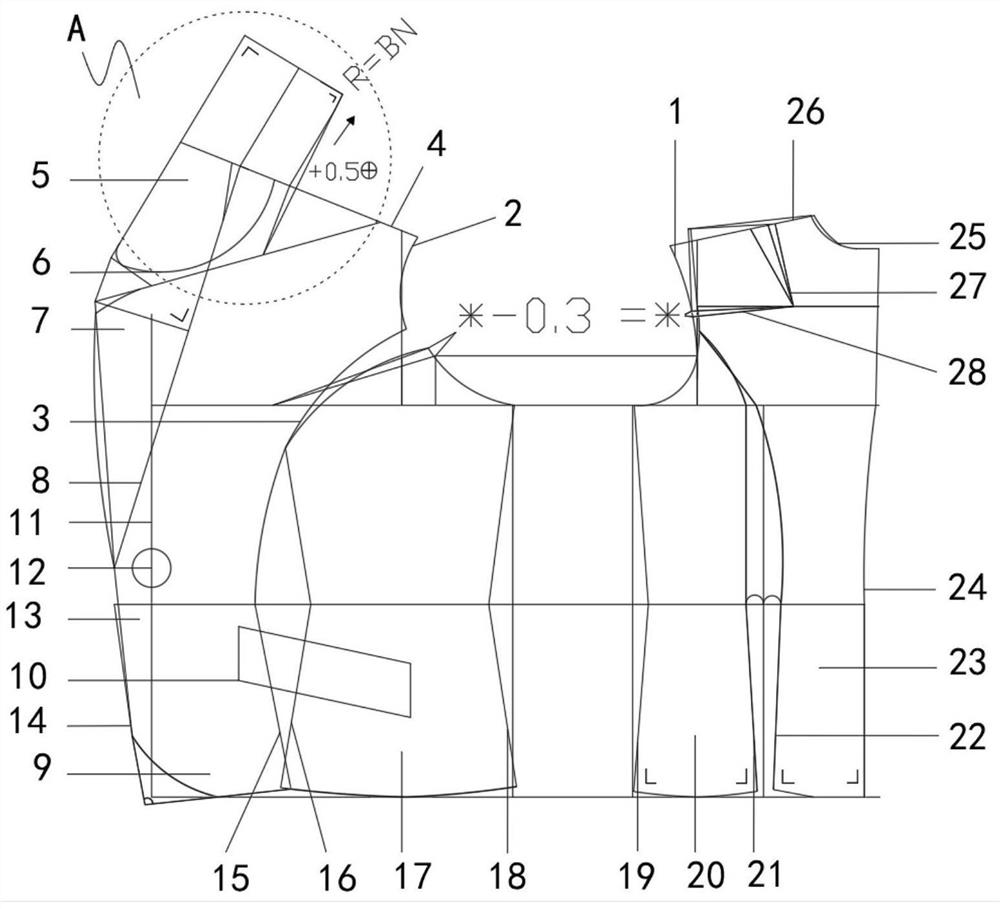

[0003] The technical problem to be solved by the present invention is to overcome the defects of the prior art. The present invention provides a round lapel suit, by first determining the position of the first dart according to the arc edge of the left front chest armhole, and

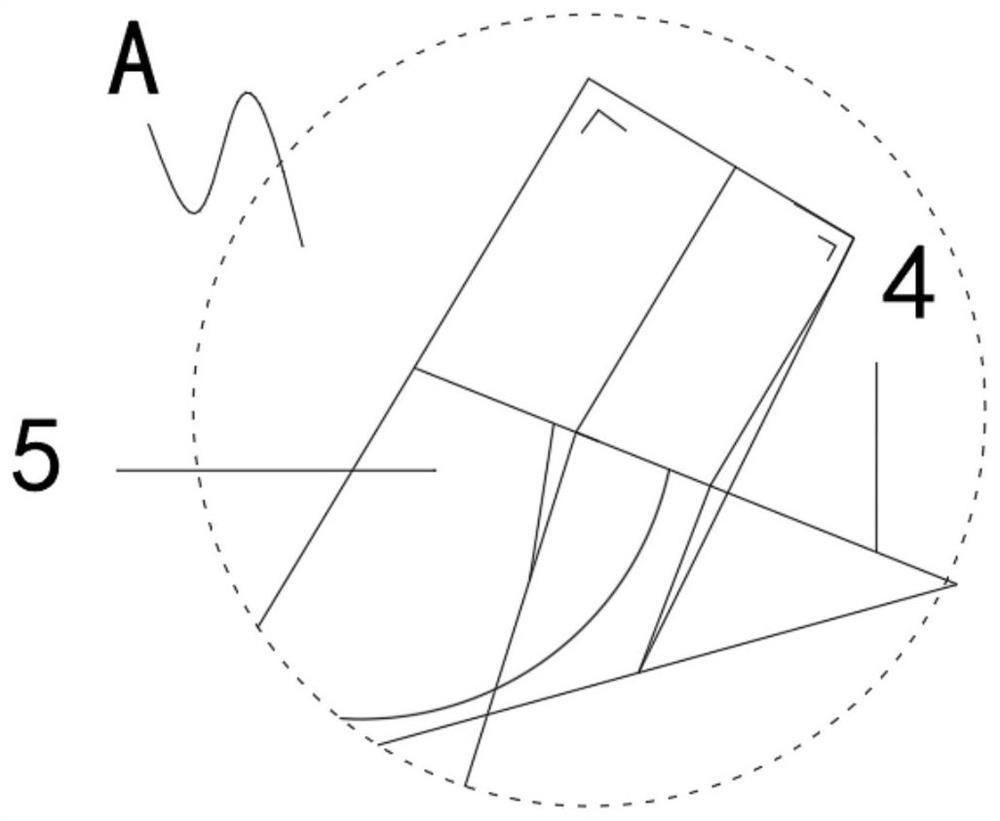

cutting on the surface of the front chest piece Exit the first dart, and then determine the position of the seam edge of the front shoulder according to the first dart, and the first dart makes the arc of the left front armhole more three-dimensional, so that the arc of the left front armhole fits the wearer better body, and

cut along the seam edge of the front shoulder, and then determine the position of the front neckline according to the seam edge of the front shoulder, and the seam edge of the front shoulder is designed according to the shoulder of the

human body. The wearer's shoulders have enough room to move, and then determine the position of the upper left collar and the lower left collar through the front neckline, and

cut out the upper left collar and the lower left collar, and the upper left collar and the lower left collar play a decorative role. At the same time, the upper left collar piece and the lower left collar piece can make the front chest piece more fit the

human body, and the collar piece fold line is formed by folding the left upper collar piece and the left lower collar piece, and then the collar piece fold line determines the position of the pocket patch , and

cut a pocket patch on the surface of the front chest piece, and the pocket patch can allow the wearer to carry small items, which brings convenience to the wearer; determine the position of the welt

contour line according to the pocket patch, and follow the The welt outline is cut, and the position of the button is determined according to the welt outline. On the one hand, the button plays a role of connection, on the other hand, it plays a role of decoration, and buttons are sewn on the surface of the front chest piece. Then determine the position of the laminated placket according to the buttons, and cut out the laminated placket, determine the position of the placket opening and closing line through the laminated placket, and cut along the placket opening and closing line, and the placket opening and closing The line can outline the line of the front chest of the

human body; determine the position of the stitching line of the front chest according to the front chest, and then determine the position of the front side piece according to the stitching line of the front chest, and cut out the front side piece, and then according to the front side The seams of the first front side panel and the second front side panel are determined by the seam, and the design of the front side panel can fully highlight the wearer's chest line, and at the same time, it can also make the front chest of the round lapel suit It has a more three-dimensional effect, thereby arousing consumers' enthusiasm for appreciation, and then the position of the first rear side panel seam is determined by the second front side panel seam line, and then the position of the rear side panel is determined by the first rear side panel seam line. Position, and cut out the back side piece, and then determine the seam line of the second back side piece through the back side piece, and the design of the back side piece can fully highlight the back line of the wearer, and at the same time make the back of the lapel collar suit The back piece has a more three-dimensional effect; determine the position of the back piece seam line according to the second back side piece seam line, then determine the position of the back piece according to the back piece seam line, and cut out the back piece, and then according to The back piece determines the middle trace of the back, and then the position of the back neckline is determined by the middle trace of the back, and the back piece is designed to fit the wearer's back better, and is cut along the back neckline; according to the back neckline line to determine the position of the back shoulder seam edge, and cut along the back shoulder seam edge, then determine the position of the second dart according to the back shoulder seam edge, and cut out the second dart on the surface of the back piece , and the second dart can make the seam edge of the back shoulder more fit the wearer's shoulder, then determine the position of the third dart according to the second dart, and cut out the third dart on the surface of the back panel , and then determine the position of the arc edge of the left back armhole through the third dart, and cut along the arc edge of the left back armhole, and the third dart can make the arc edge of the left back armhole fit, so that the left The curved edge of the back armhole has a more three-dimensional effect; the position of the convex line of the left armhole seam and the concave line of the left armhole seam are determined by the curved edge of the left front chest armhole, and along the convex line of the left armhole seam and the left The concave line of the armhole seam is cut, and the convex line of the left armhole seam and the concave line of the left armhole seam can make the

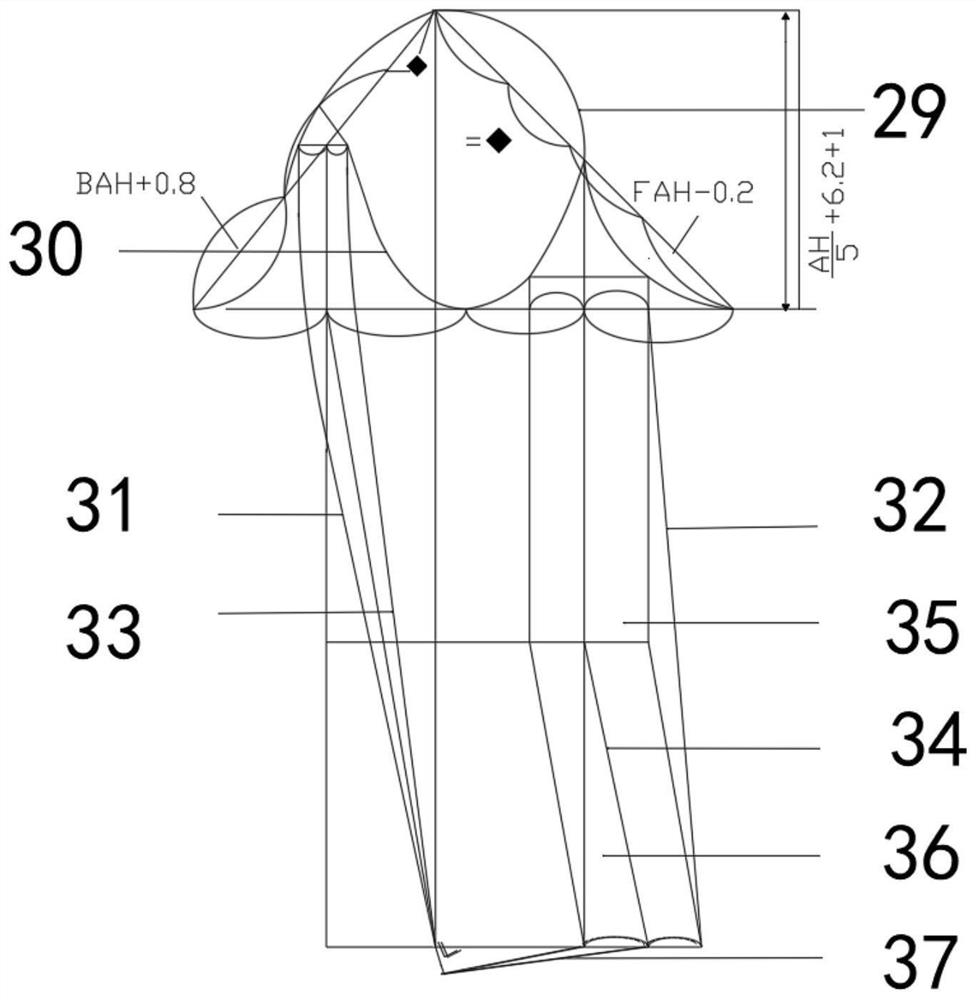

scapula part of the human body have enough room for movement, and then determine according to the convex line of the left armhole seam The position of the inner edge of the first left armhole seam and the outer edge of the first left armhole seam, and then determine the inner edge of the second left armhole seam and the second left armhole seam according to the inner concave line of the left armhole seam Then determine the position of the first sleeve according to the inner edge of the first left armhole seam and the outer edge of the first left armhole seam, and cut out the first sleeve, and the first sleeve is based on the It is designed so that the arms have enough room to move, and then the position of the second sleeve is determined according to the inner edge of the second left armhole seam and the outer edge of the second left armhole seam, and the second sleeve is cut out. And the second sleeve piece can make the sleeve part have a three-dimensional effect, and finally determine the position of the

cuff through the second sleeve piece, and cut out the

cuff; finally through the arc edge of the left back armhole, the arc edge of the left chest armhole, the second dart collar, upper left collar piece, lower left collar piece, front chest piece, pocket patch, buttons, laminated placket, front side panel, back side panel, back back piece, 2nd dart, 3rd dart, left armhole The combined splicing structure of the convex line of the seam, the concave line of the left armhole seam, the first sleeve piece, the second sleeve piece and the

cuff forms a round lapel suit, and through such combination stitching, the round lapel suit can be made It is more exquisite and delicate, and solves the problem mentioned in the above background technology. Nowadays, most of the round lapel suits are only designed with front chest and back. Such round lapel suits cannot fully highlight the wearer's body line. This invisibly reduces consumers' enthusiasm for appreciating round lapel suits. Not only that, some round lapel suits are designed with front chest, back and side panels, which can increase the appeal of round lapel suits. However, it is still unable to fully highlight the body shaping effect of the wearer, and it also limits the enthusiasm of some consumers for appreciating round lapel suits.

Login to view more

Login to view more