Variable-gradient load mechanism

A load and gradient technology, applied in the direction of human manipulation, control start method, etc., can solve the problems of low yield rate, limited spring manufacturing precision, and inability to eliminate, so as to reduce the manipulation burden and improve the operation precision.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032]In order to make the objects, technical solutions, and advantages of the present application, the technical solutions in the present application embodiment will be described in more detail below in connection with the drawings in the present application embodiment.

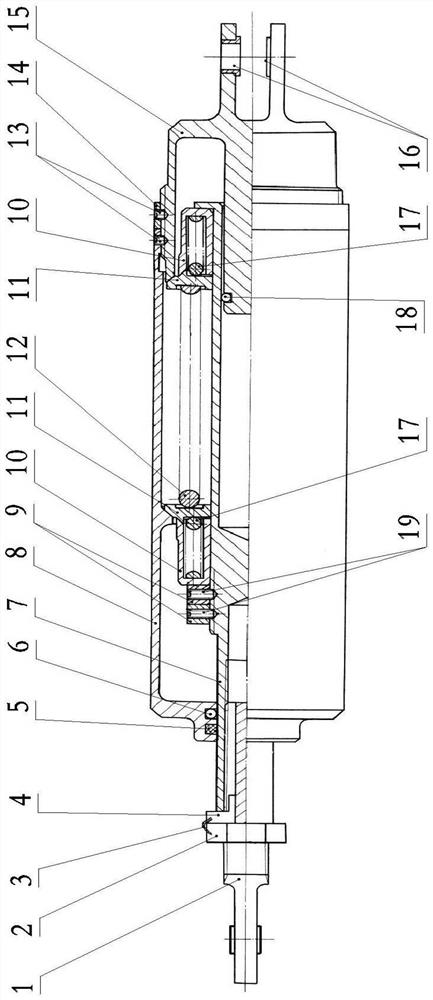

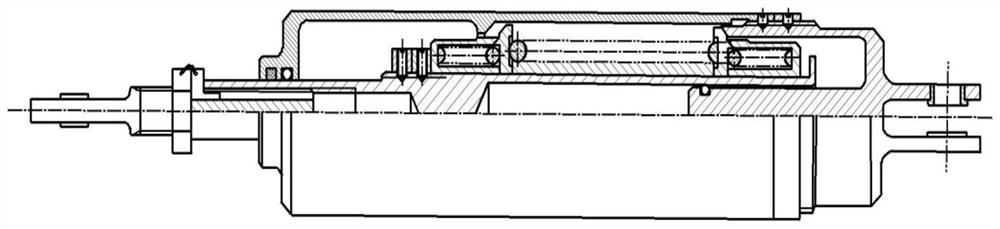

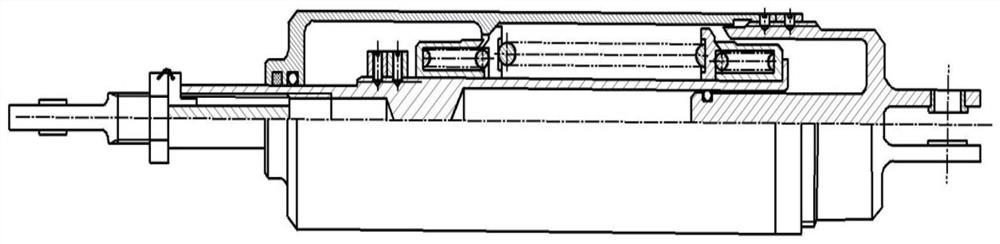

[0033]Such asFigure 1 to 9 As shown, the gradient load mechanism provided herein mainly includes: the earrings 1, the rear housing 15, the core rod 7, the bushing 10, the first spring 17, the second spring 12, and the main casing 8, and the like. The core rod 7 is disposed between the earrings 1 and the rear housing 15, the core rod 7 relative to the earrings 1, and the other end can be moved relative to the rear housing 15.

[0034]In one embodiment of the present application, the mandrel 7 and the earrings 1 are limited by the nut 2 that is screwed into the earrings 1. When installing, the earrings 1 is screwed into the thread of the core rod 7, and at the same time, with the limit key 4, the slot of the limit slot of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com