Garbage can assembly structure with universal can body

A technology for assembling structures and trash cans, which is applied in the field of daily necessities, can solve the problems of increasing the burden on enterprises, increasing the cost of users, and damage to the opening mechanism, so as to reduce the burden on enterprises, reduce the cost of upgrading, and simplify the overall structure.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

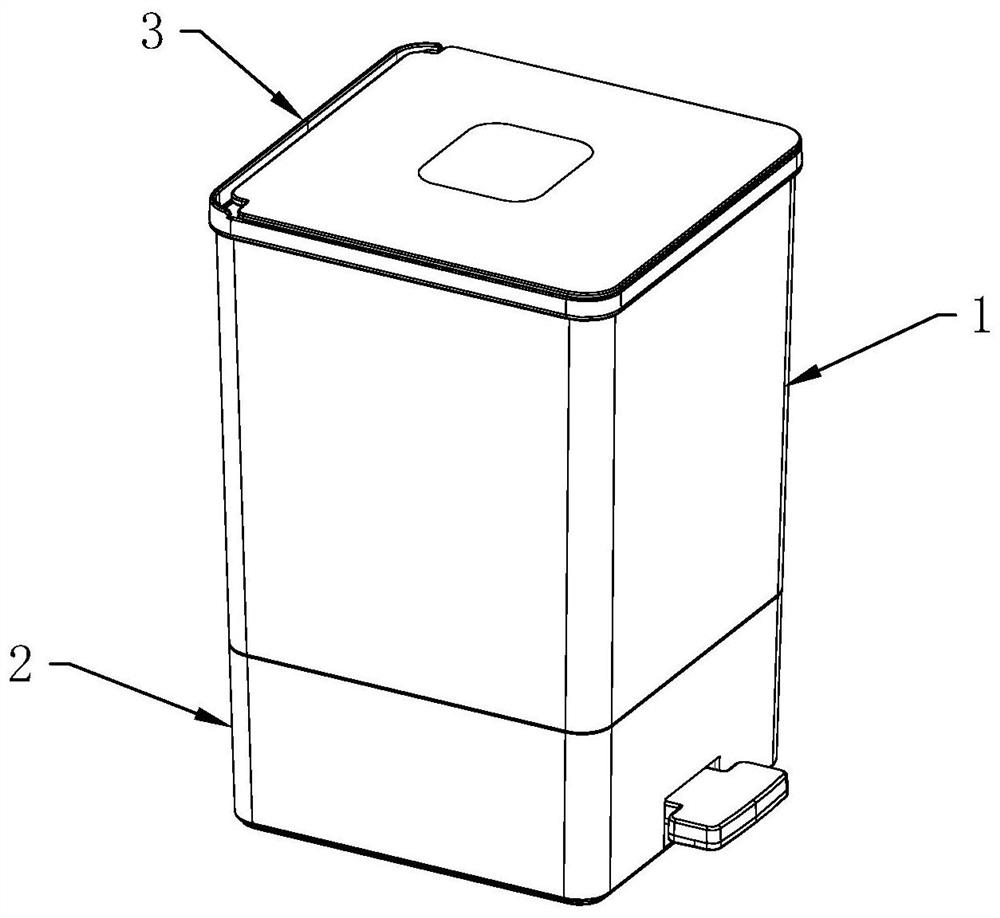

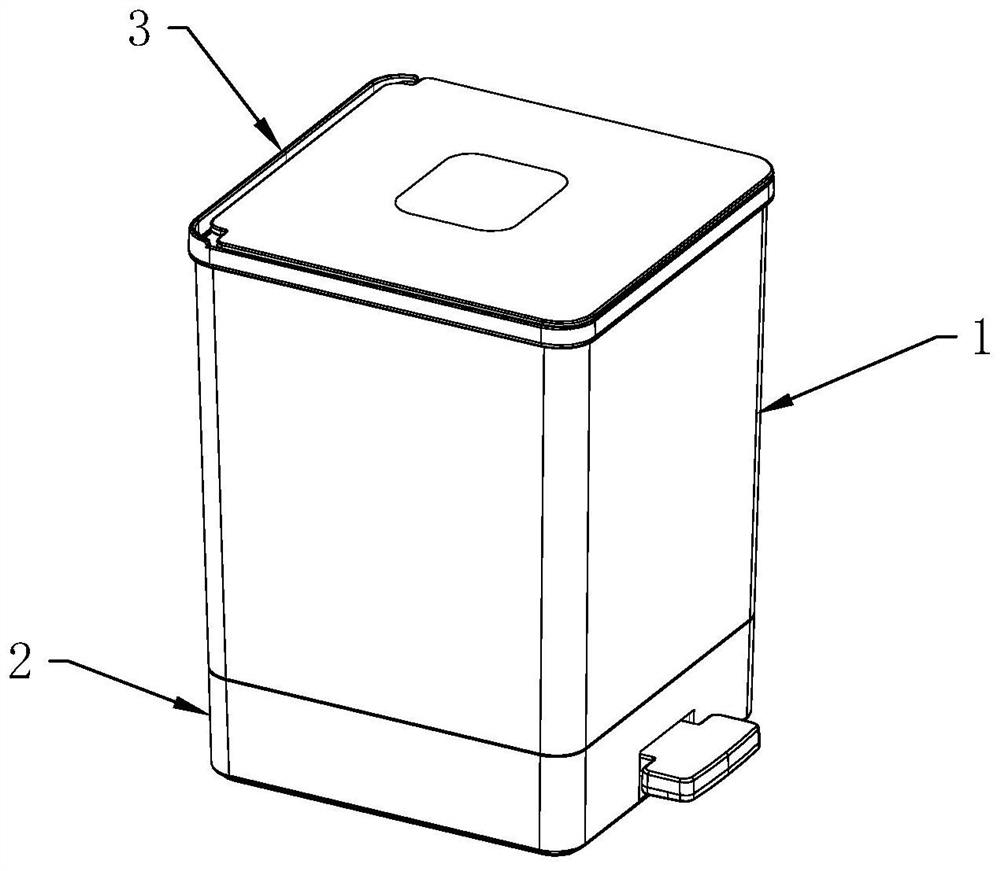

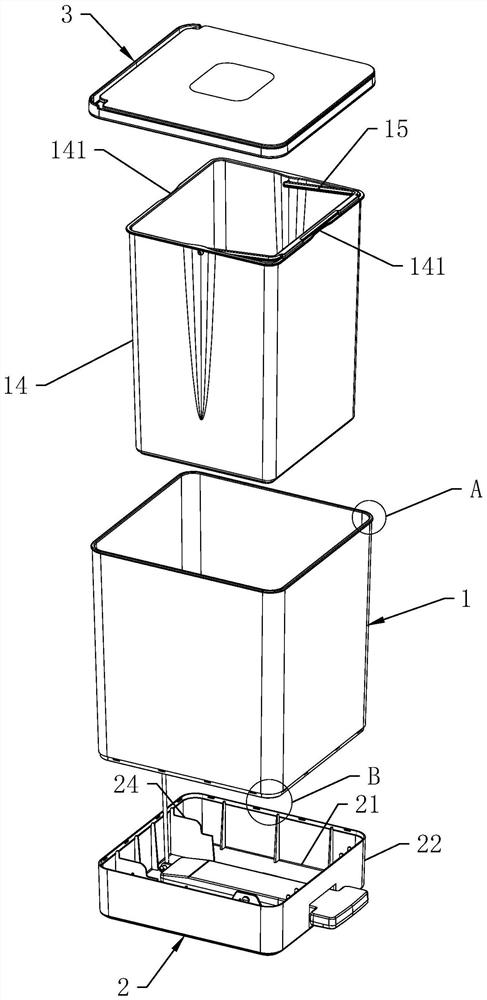

[0034] Such as figure 1As shown, a trash can assembly structure with a universal barrel body according to the present invention includes a universal barrel body 1, a barrel bottom 2, and a lid assembly 3, wherein the universal barrel body 1 is a barrel structure that penetrates up and down, so The bucket bottom 2 is detachably mounted on the lower port of the universal bucket body 1 , and the bucket lid assembly 3 is detachably mounted on the upper port of the universal bucket body 1 . The garbage can assembly structure of the present invention includes a general bucket body 1, a bucket bottom 2, and a bucket lid assembly 3, and the bucket lid assembly 3 and the bucket bottom 2 are respectively detachably mounted on the upper and lower ports of the universal bucket body 1. By adopting the universal barrel body 1, this can meet the general demand of not using a trash can, and because the upper part of the existing trash can body does not need to be upgraded or redesigned for a ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com