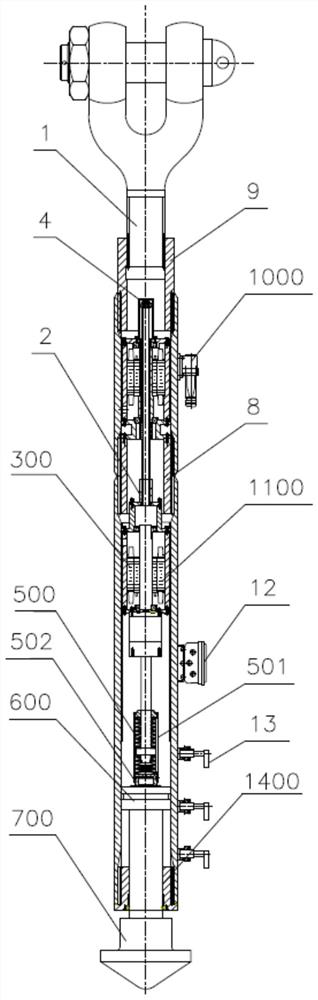

Electric telescopic and spin-locked windproof pull rod

A technology of electric telescopic and twist lock, which is applied in the direction of transportation and packaging, load hanging components, traveling mechanism, etc., and can solve problems such as incompatibility, time-consuming and labor-intensive, and inability to realize automation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

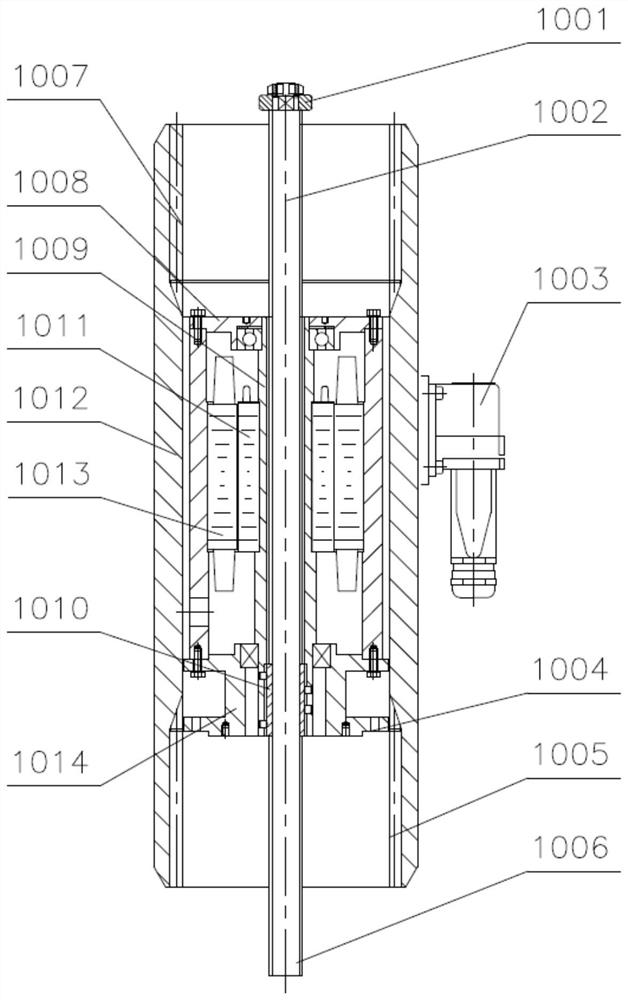

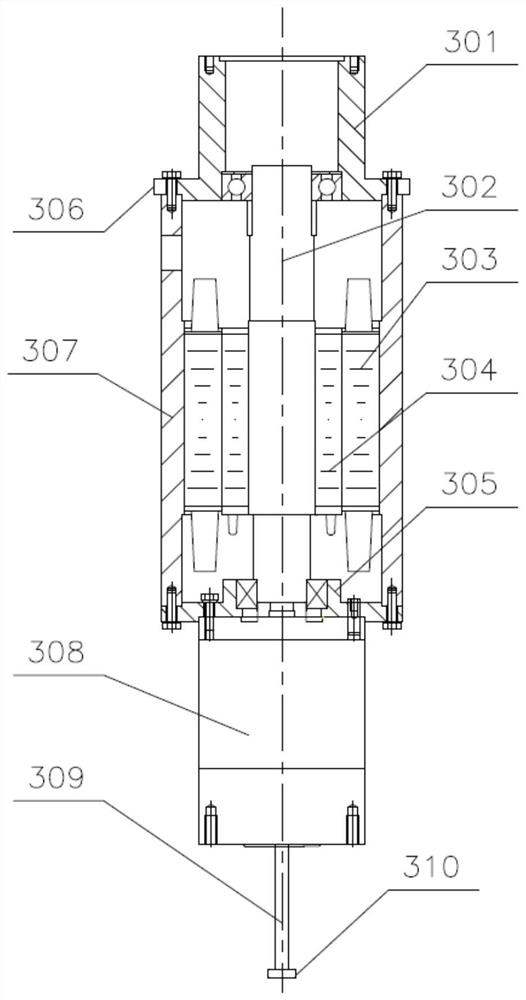

[0055] Embodiment 1, when the ground anchorage is an open type in the running direction of a large mechanical cart (the lock shaft telescopic motor 1000 works, and the lock rotation reduction motor 300 does not work):

[0056] The large-scale machinery in the container terminal is positioned by the induction limit or the encoder, and walks to the side of the anchor position; the lock shaft telescopic motor 1000 in the embodiment of the present invention is started, and the motor shaft 1009 drives the nut 1010 in the shaft hole to rotate, driving the telescopic screw shaft 1002 moves downward, drives the rotating motor 300 to slide downward together, and makes the lock head of the lock head shaft 700 vertically drop to the middle of the ground anchor seat lock body through the buffer coupling 500, and the lock head of the lock head shaft 700 spins the lock hook anchor When the surface 705 is lower than the articulated surface of the lock body of the anchor seat, the telescopic m...

Embodiment 2

[0058] Embodiment 2, when the ground anchorage is plug-in type:

[0059] The large-scale machinery in the container terminal is positioned by the induction limit or the encoder, and walks above the anchor position insertion hole; the lock shaft telescopic motor 1000 in the embodiment of the present invention is started, and the motor shaft 1009 drives the nut 1010 in the shaft hole to rotate, driving the telescopic wire The rod shaft 1002 moves downwards, drives the rotating motor 300 to slide down together, and through the buffer coupling 500, the lock head of the lock head shaft 700 is vertically dropped and inserted into the middle of the ground anchor lock body, and the lock head hook of the lock head shaft 700 When the anchor surface 705 is lower than the articulated surface of the anchor seat lock body, the lock shaft telescopic motor 1000 stops automatically according to the position information detected by the position sensor 13; 500 makes the lock of the lock shaft 70...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com